High pressure washdown system with multiple sets of mechanical seals

A mechanical seal and flushing system technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of centrifugal pumps not working normally, centrifugal pumps unable to withstand high pressure, centrifugal pump leakage, etc., to achieve small footprint , improved pressure bearing capacity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

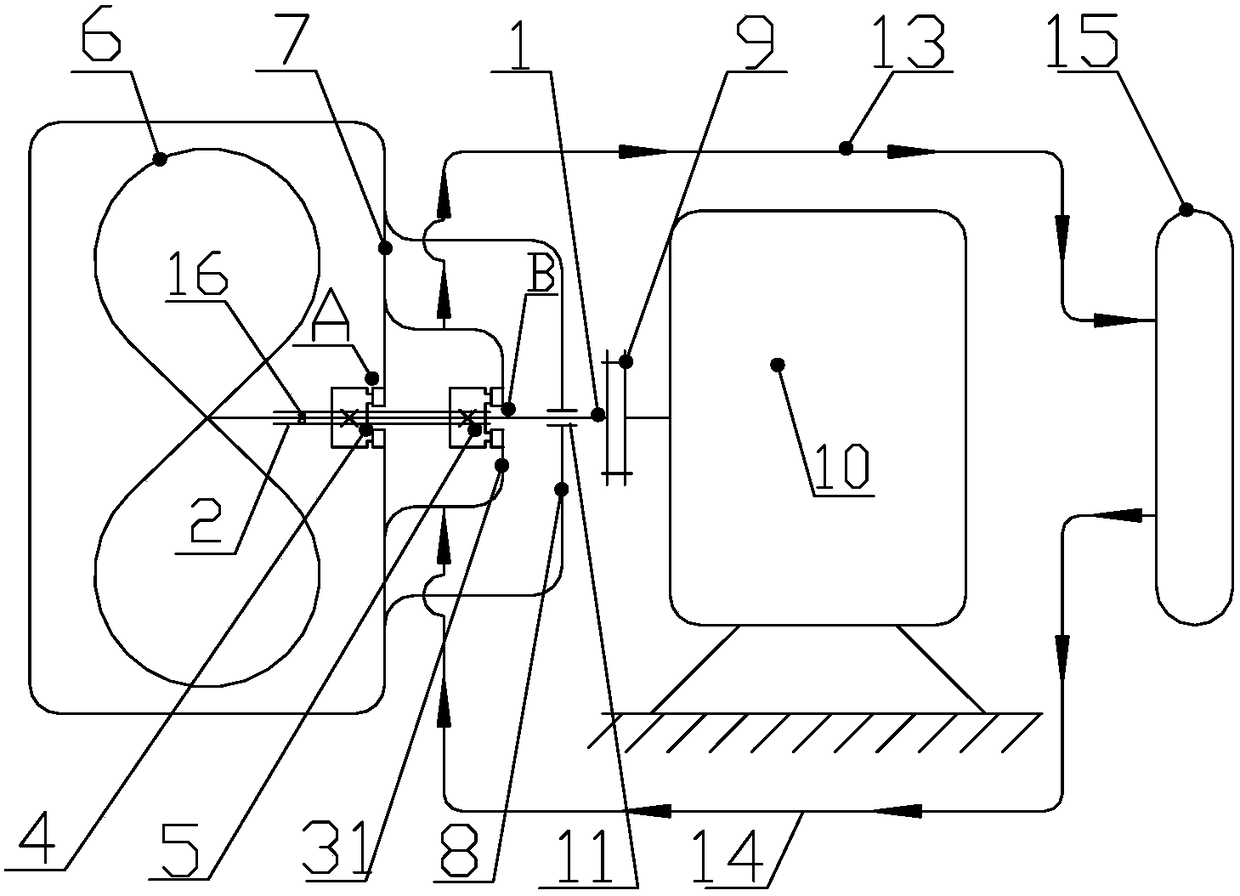

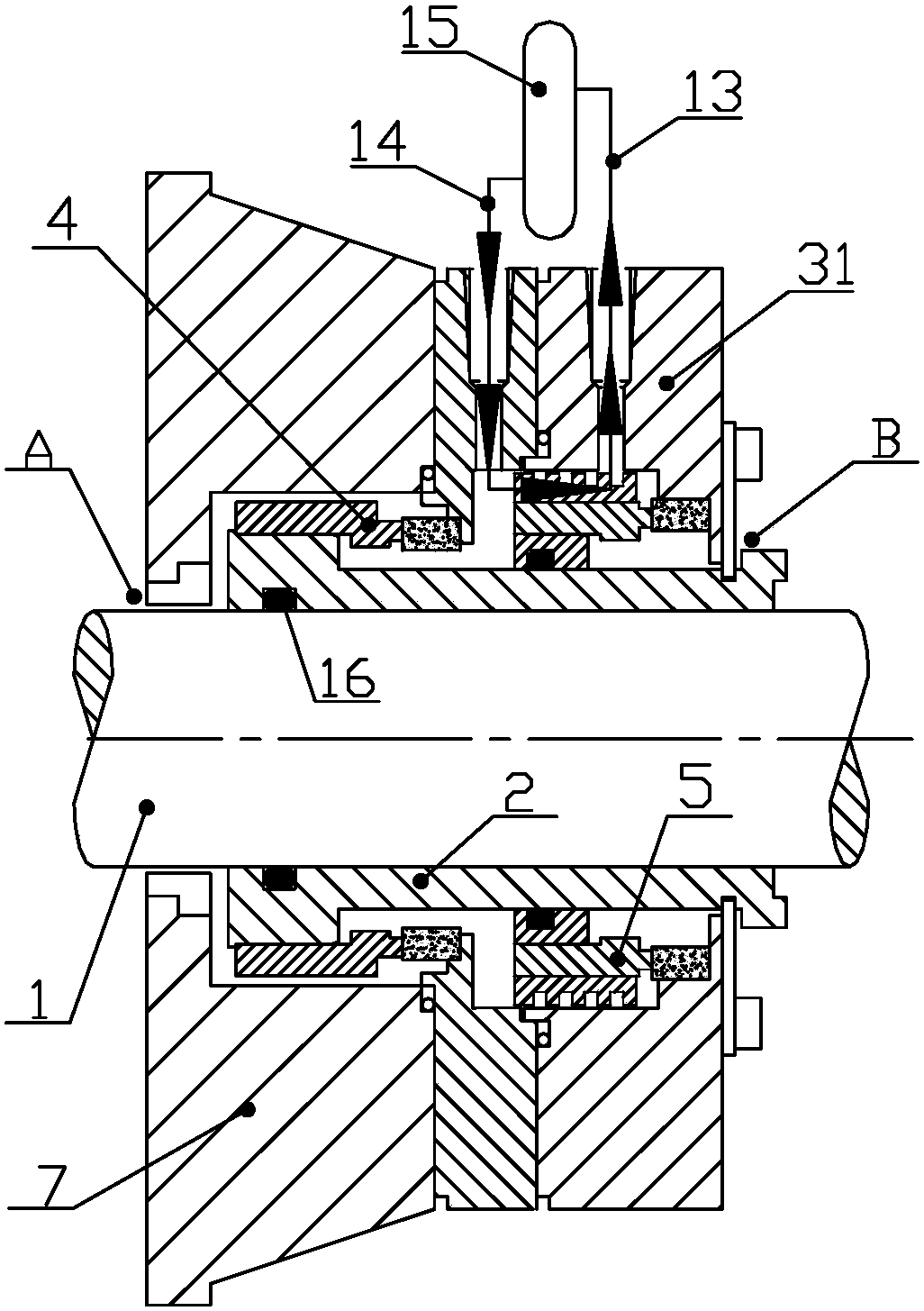

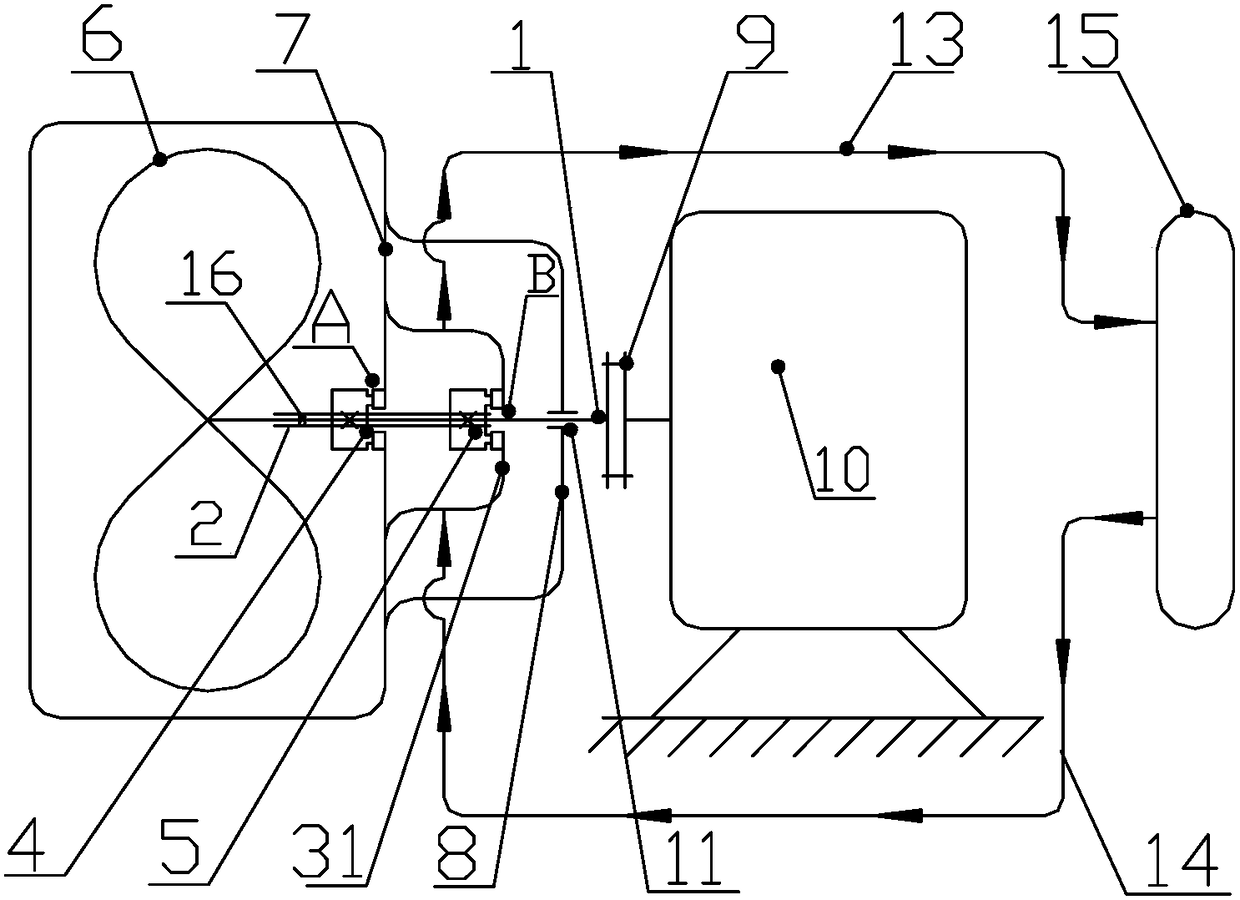

[0055] The high-pressure flushing system with multiple sets of mechanical seals of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0056] like Figure 5 , Image 6 As shown, the high-pressure flushing system with multiple sets of mechanical seals of the present invention includes a centrifugal pump composed of a pump casing 7, an impeller 6 arranged in the pump casing 7, and a pump shaft 1 connected to the impeller 6 at one end. The other end of the pump shaft 1 extends out of the pump casing 7 through the high-pressure end mechanical seal 4 arranged on the shaft outlet hole of the pump casing 7, and the end is connected to the motor 10 for driving the impeller 6 to rotate through a coupling 9. The end of the pump shaft 1 connected to the shaft coupling 9 is positioned through the bearing 11 arranged on the bearing seat 8, and the outside of the pump shaft 1 is covered with a shaft sleeve 2, and the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com