Plunger ported axial plunger hydraulic pump

A hydraulic pump and plunger technology, applied in the field of positive displacement pumps, can solve the problems of high production cost, poor lubricity, high noise, etc., to reduce manufacturing difficulty and production cost, improve work reliability and service life, and improve rating The effect of outgoing traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation state of the present invention is further described below in conjunction with accompanying drawing:

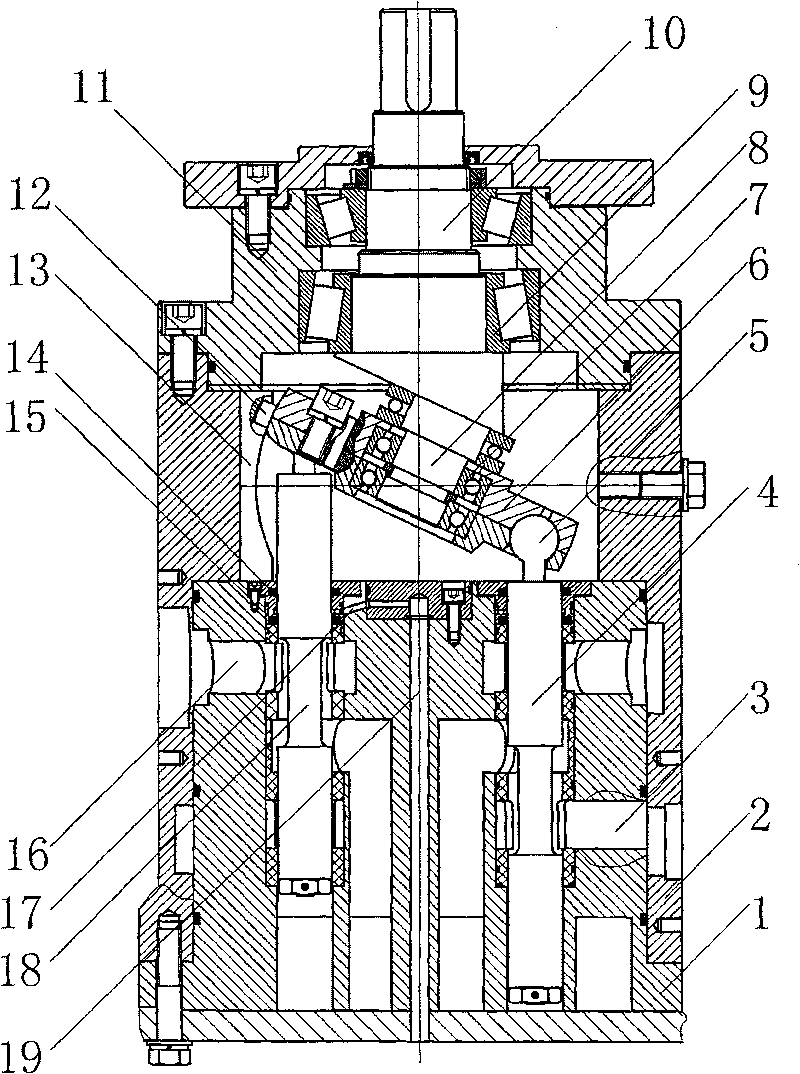

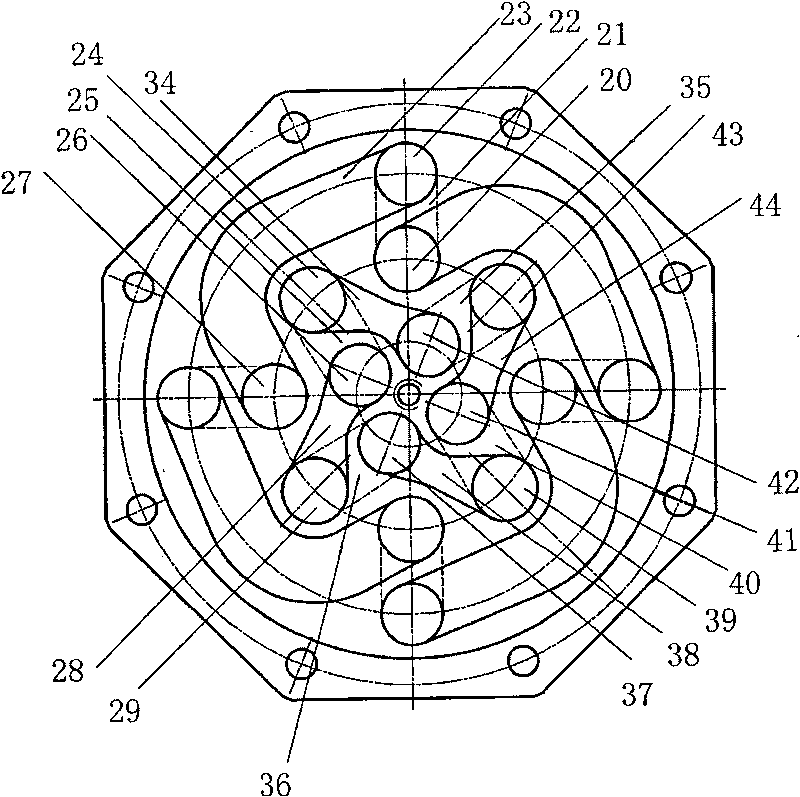

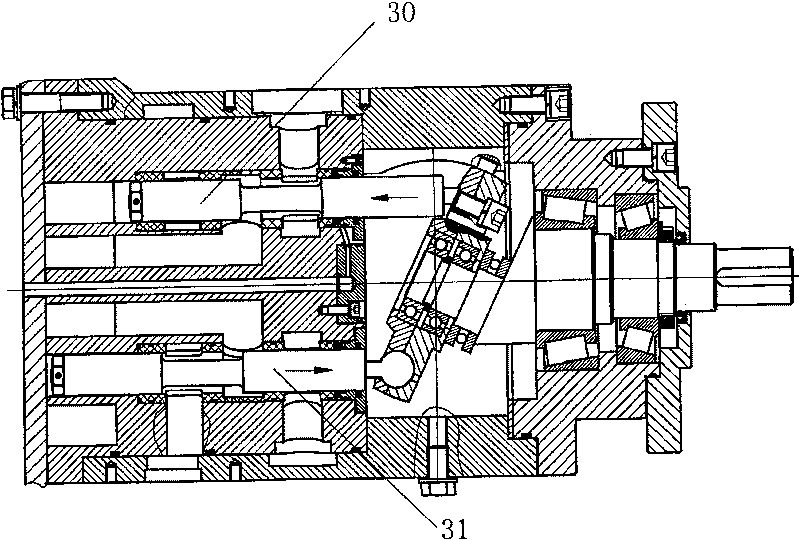

[0025] figure 1 Shown is an embodiment of the present invention, which adopts the end face spiral swash plate connecting rod crankshaft axial plunger structure. The crankshaft 10 is installed on the end cover 11 through the tapered roller bearing 9, and the axis of the crankshaft 8 of the crankshaft forms an acute angle of 25° with the axis of the crankshaft 10; the swash plate 6 is installed on the crankshaft 8 of the crankshaft through the angular contact bearing 7; 6 is installed with a guide and positioning slider 12, and the guide and positioning slider 12 slides back and forth axially in the guide chute 13 fixed on the pump housing 2; On the index circle of the ball joint rod, the other ball head of the ball joint rod is connected with the plunger 4; the ball joints formed by the ball heads on both sides adopt combined ball socket limit; the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com