Vertical single eccentric shaft radial equipartition multi-connection reciprocating pump

A single eccentric, shaft radial technology, used in the field of reciprocating pumps, can solve the problems of limited elastic force, difficulty in lubricating and cooling the eccentric wheel and bearing bush, and short life, and achieve the effect of increasing the contact surface, compact structure, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

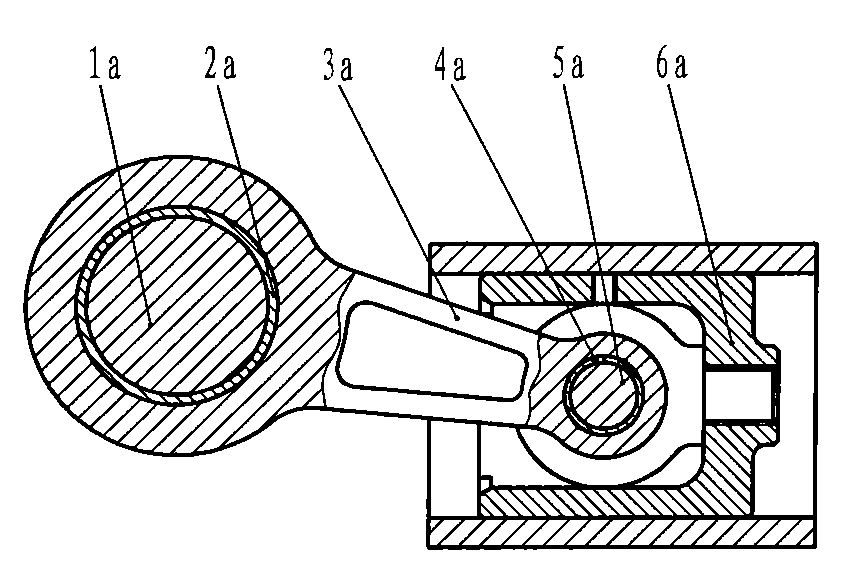

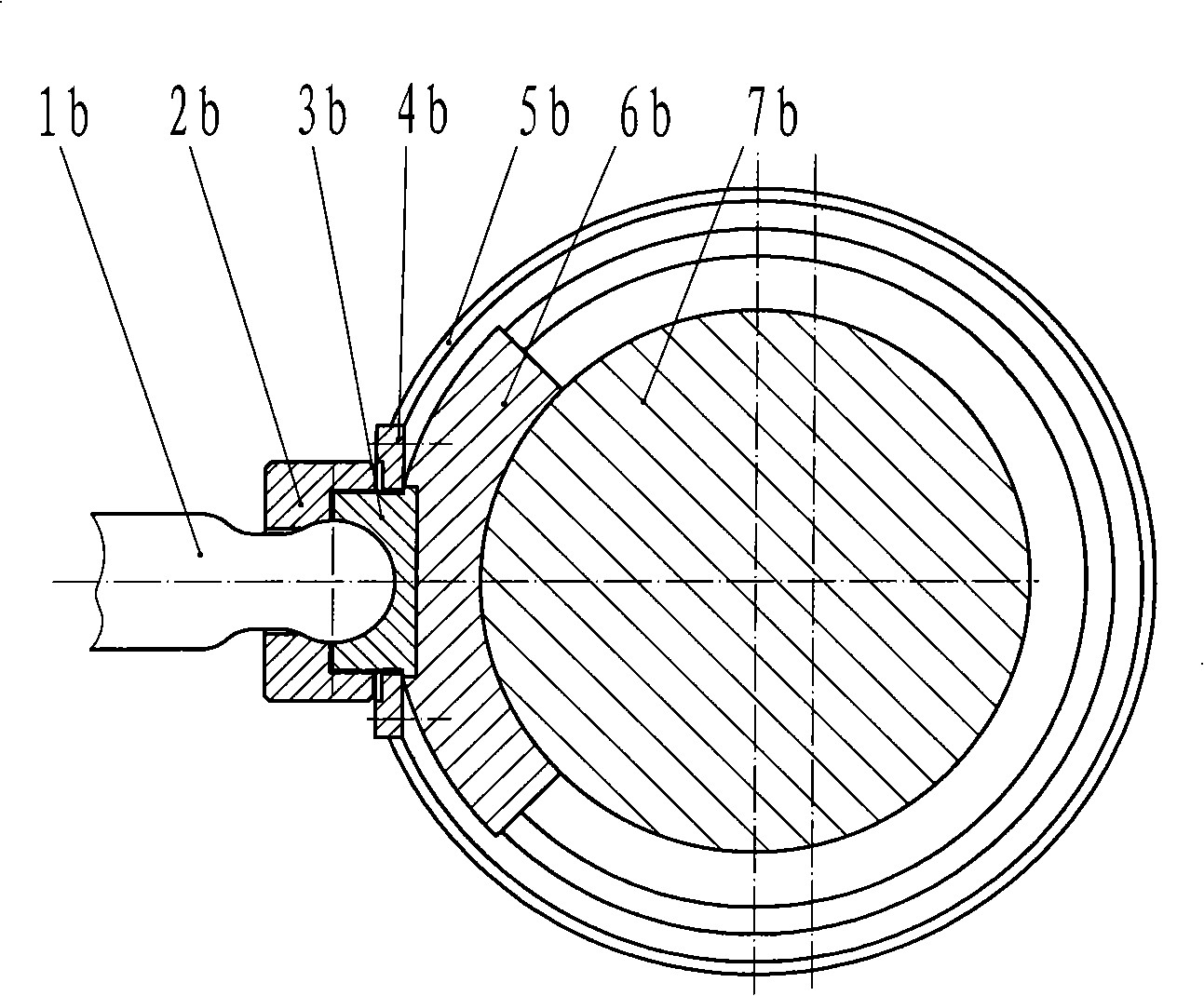

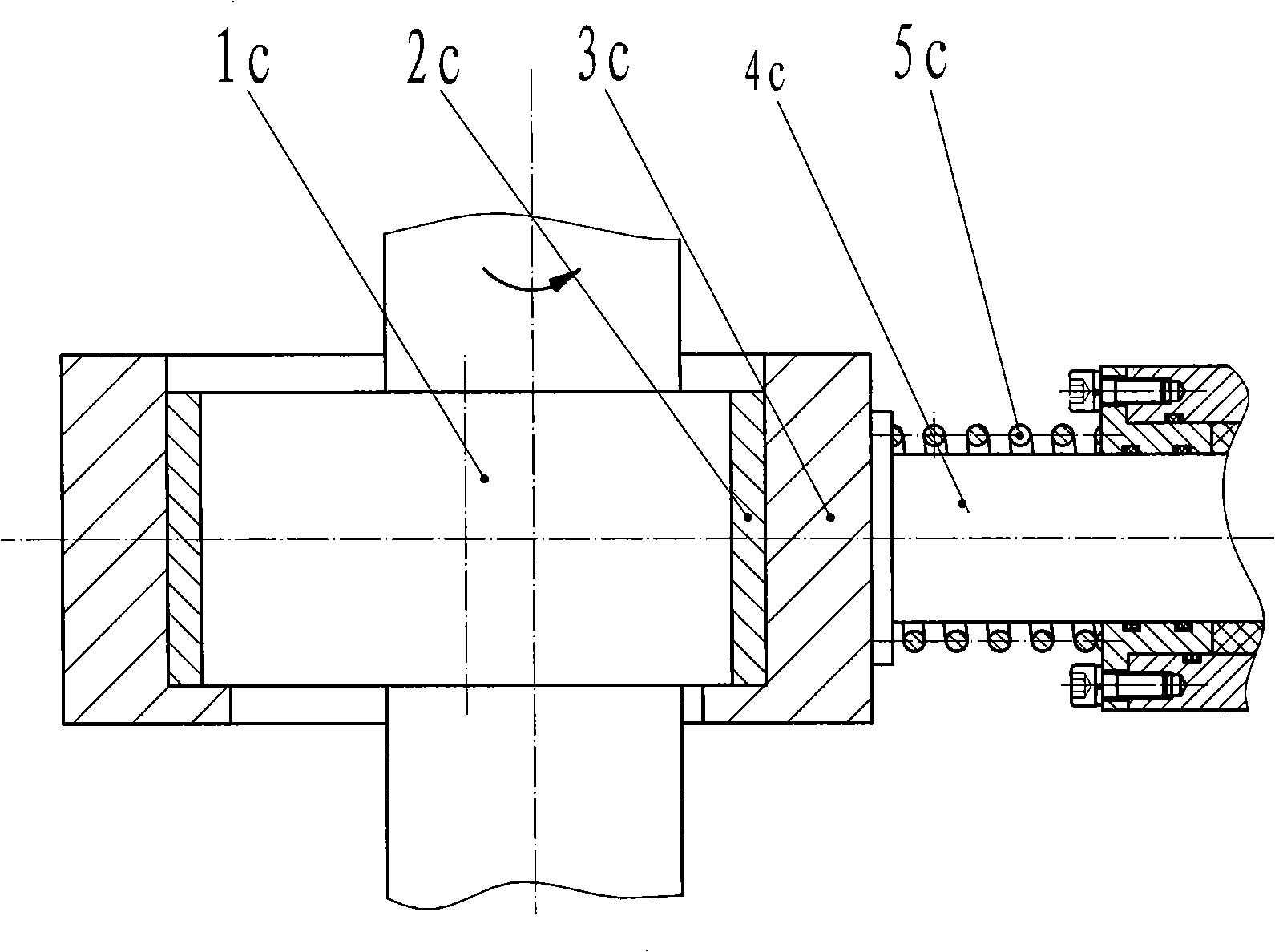

[0015] see Figure 4-5 : a vertical single eccentric shaft radially evenly distributed multi-connected reciprocating pump, including a pump body 1, a plurality of plunger grooves are uniformly distributed along the circumferential direction on the pump body 1, and the plunger 8 can be radially slidably arranged on the In the plunger groove, the pump cavity of the pump body 1 is provided with a rotating body that drives the plunger 8 to move. The rotating body includes an eccentric wheel 5 that rotates eccentrically. 3 is sleeved on the guide sleeve 7 outside the eccentric wheel 5, the rolling bearing 3 includes an inner ring 11, balls, and an outer ring 13, the inner ring 11 is fixed on the eccentric wheel 5, and the outer ring 13 is fixed to the bearing sleeve 2 , the bearing sleeve 2 is fixedly connected with the guide sleeve 7, an annular groove 14 is formed between the inner wall 15 of the guide sleeve 7 and the outer wall 6 of the bearing sleeve 2, and the head of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com