Method for obtaining surface contact rigidity based on system characteristic frequency, and detection apparatus thereof

A characteristic frequency and surface contact technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as the difficulty in contact stiffness of the contact pair surface, and achieve the effects of ensuring repeatability, easy positioning, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the working principle and the structural drawings.

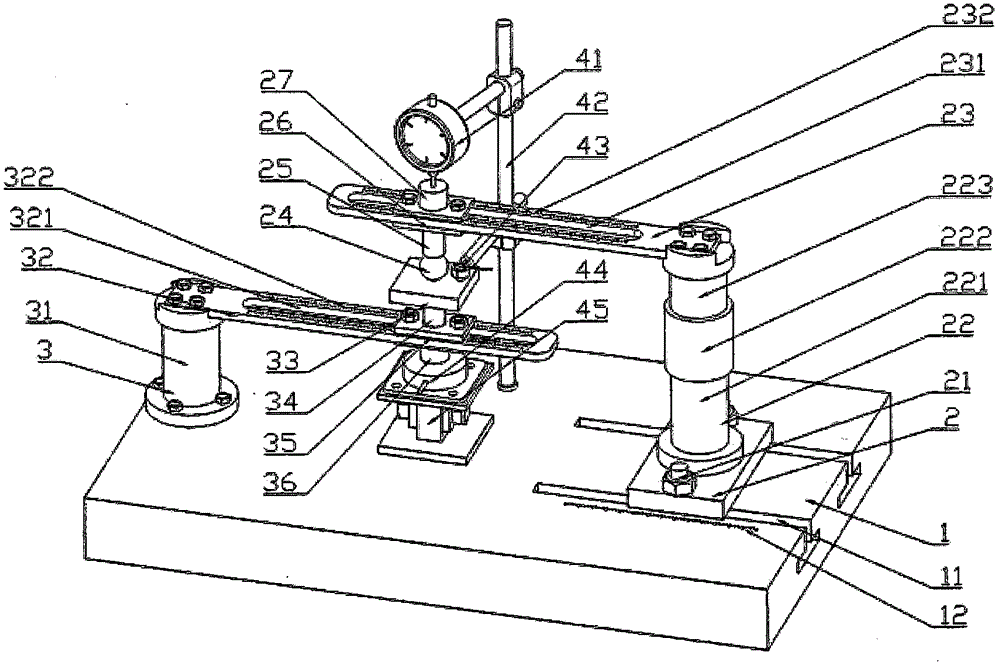

[0030] Such as figure 1 , the surface contact stiffness detection device of the present invention includes a base (1), an upper elastic mechanism (2), a lower elastic mechanism (3), a contact sample alignment mechanism (not marked in the figure), an initial condition testing mechanism ( Not marked), vibration information collection mechanism (not marked in the figure) and computer (not shown in the figure) and other components.

[0031] The upper single-degree-of-freedom elastic mechanism consists of a T-shaped block (21), a movable support column (22), an upper elastic beam (23), an upper guide groove (231), a sample one (24), a sample one fixed seat (25 ), the upper beam fastening slide (26), etc., wherein the movable support column (22) includes an upper column (223) with an external thread, a lower column (221) and a sleeve (222) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com