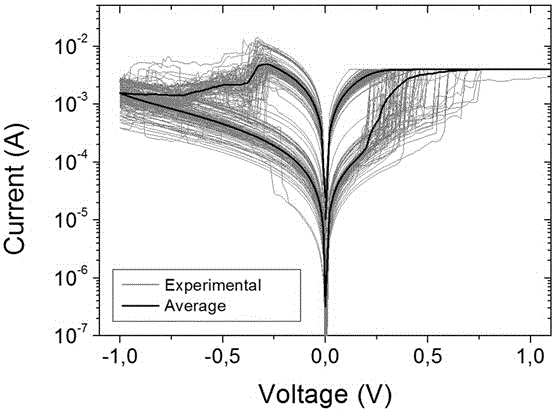

Multi-layer boron nitride based RRAM device and preparation method therefor

A multi-layer boron nitride and boron nitride technology, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of random resistive memory with unstable electrical properties and easy decay, so as to prevent pollution and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

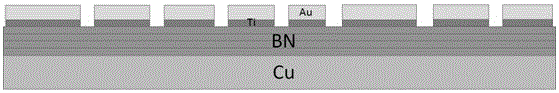

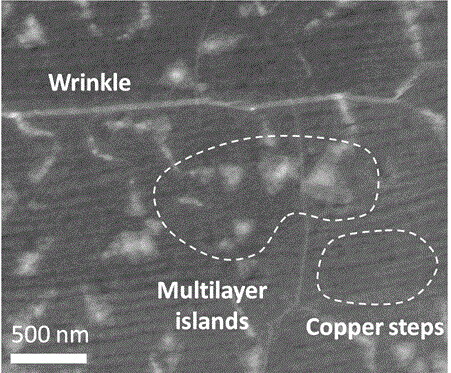

[0029] (1) Boron nitride is grown by chemical vapor deposition, using borazane as a precursor, annealing the copper foil for 30 minutes in a hydrogen environment of 10 sccm and a low pressure of 1000 ° C, and the growth temperature of boron nitride is kept at 750°C, the time is controlled at 15 minutes, the flow rate of borazane is 3sccm, and the flow rate of hydrogen gas is 2000sccm; after the growth is completed, the boron nitride / copper foil is annealed in 100sccm hydrogen and 100sccm nitrogen environment for 1 hour, and the annealing temperature is 1000°C , that is, the final boron nitride / copper foil sample is obtained, and the substrate copper foil grown on boron nitride is used as the lower electrode of the device;

[0030] (2) Evaporate titanium electrodes and gold electrodes using an electron beam evaporation apparatus and a mask plate: slowly increase the electron beam power, the metal begins to evaporate, then increase the electron beam power until it reaches 0.5? / s ...

Embodiment 2

[0034] (1) Boron nitride is grown by chemical vapor deposition, using borazane as a precursor, annealing the copper foil for 30 minutes in a hydrogen environment of 10 sccm and a low pressure of 1000 ° C, and the growth temperature of boron nitride is kept at 750°C, the time is controlled at 15 minutes, the flow rate of borazane is 3 sccm, and the flow rate of hydrogen gas is 2000 sccm; after the growth is completed, the boron nitride / copper foil is annealed in an environment of 100 sccm hydrogen and 100 sccm nitrogen for 1 hour, and the annealing temperature is 1000 °C , that is, the final boron nitride / copper foil sample is obtained, and the substrate copper foil grown on boron nitride is used as the lower electrode of the device;

[0035] (2) Evaporate titanium electrodes and gold electrodes using an electron beam evaporation apparatus and a mask: slowly increase the electron beam power, and the metal begins to evaporate, then increase the electron beam power until it reache...

Embodiment 3

[0037] (1) Boron nitride is grown by chemical vapor deposition, using borazane as a precursor, annealing the copper foil for 30 minutes in a hydrogen environment of 10 sccm and a low pressure of 1000 ° C, and the growth temperature of boron nitride is kept at 750°C, the time is controlled at 15 minutes, the flow rate of borazane is 3 sccm, and the flow rate of hydrogen gas is 2000 sccm; after the growth is completed, the boron nitride / copper foil is annealed in an environment of 100 sccm hydrogen and 100 sccm nitrogen for 1 hour, and the annealing temperature is 1000 °C , that is, the final boron nitride / copper foil sample is obtained, and the substrate copper foil grown on boron nitride is used as the lower electrode of the device;

[0038] (2) Evaporate titanium electrodes and gold electrodes using an electron beam evaporation apparatus and a mask: slowly increase the electron beam power, and the metal begins to evaporate, then increase the electron beam power until it reache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com