A kind of carbon dioxide electrochemical reduction catalyst and its preparation and application

A carbon dioxide and catalyst technology, which is applied in the field of carbon dioxide electrochemical reduction catalyst and its preparation and application, can solve the problem of low reduction current density, achieve the effects of solving the problem of low reduction current density, improving energy efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

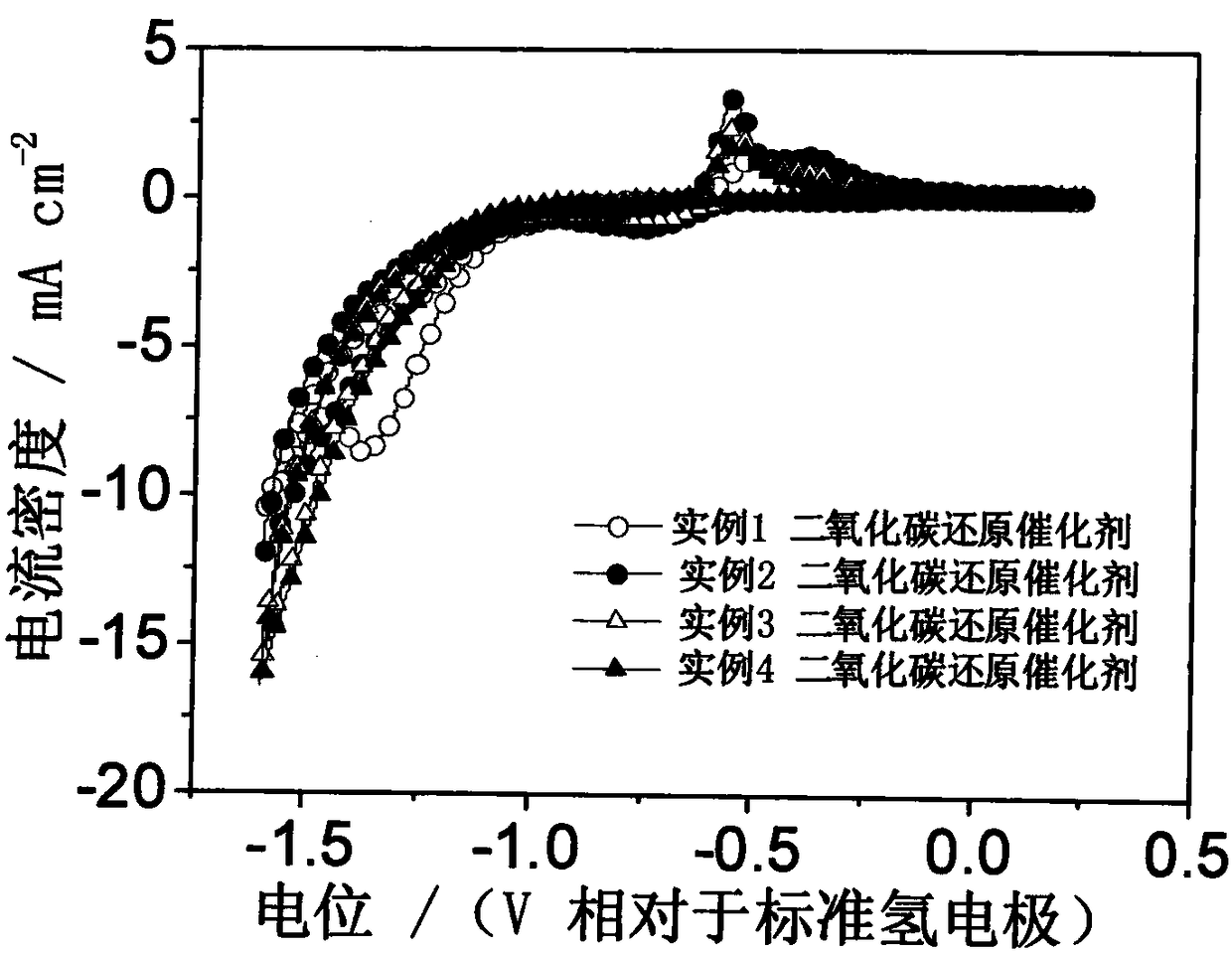

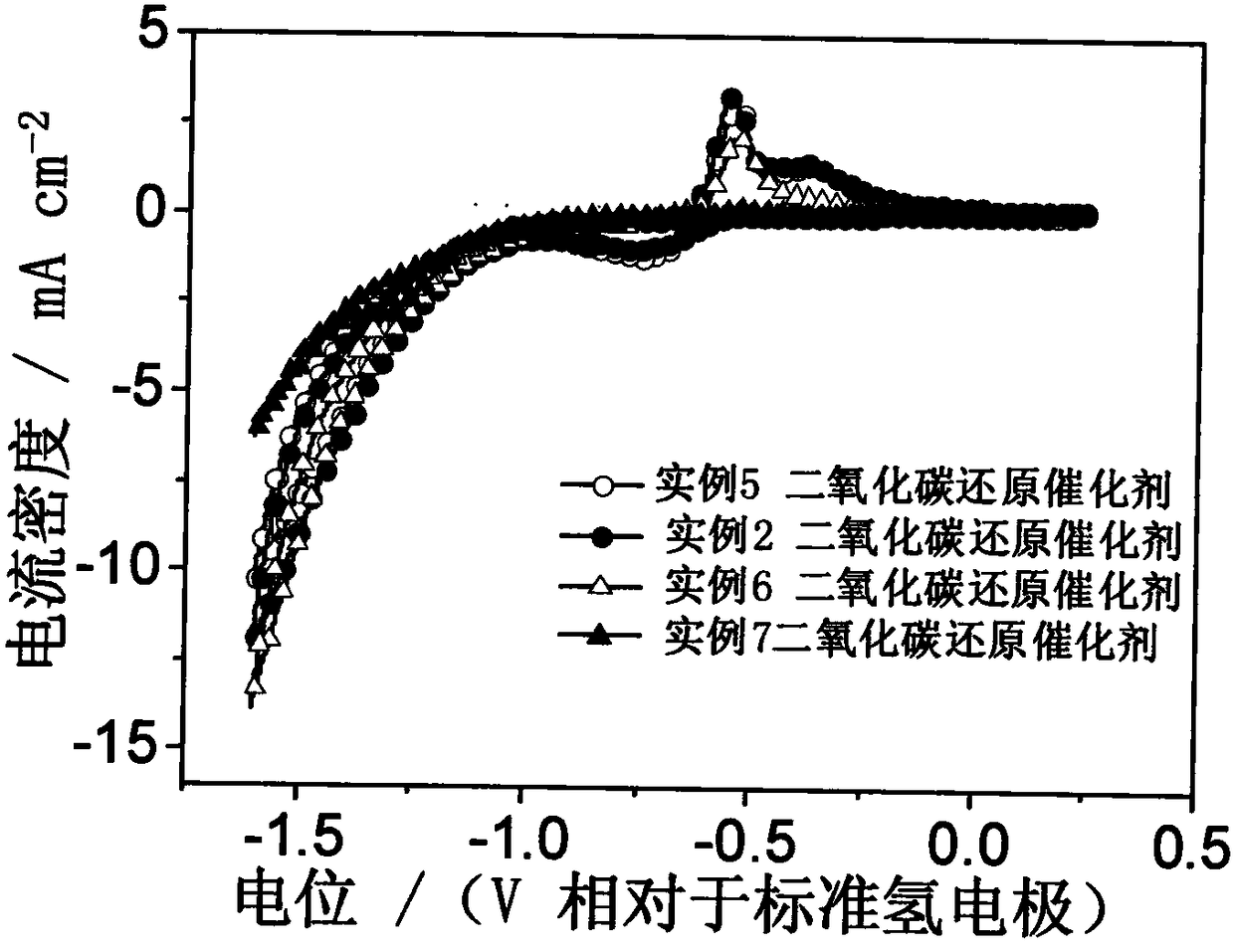

Embodiment 1

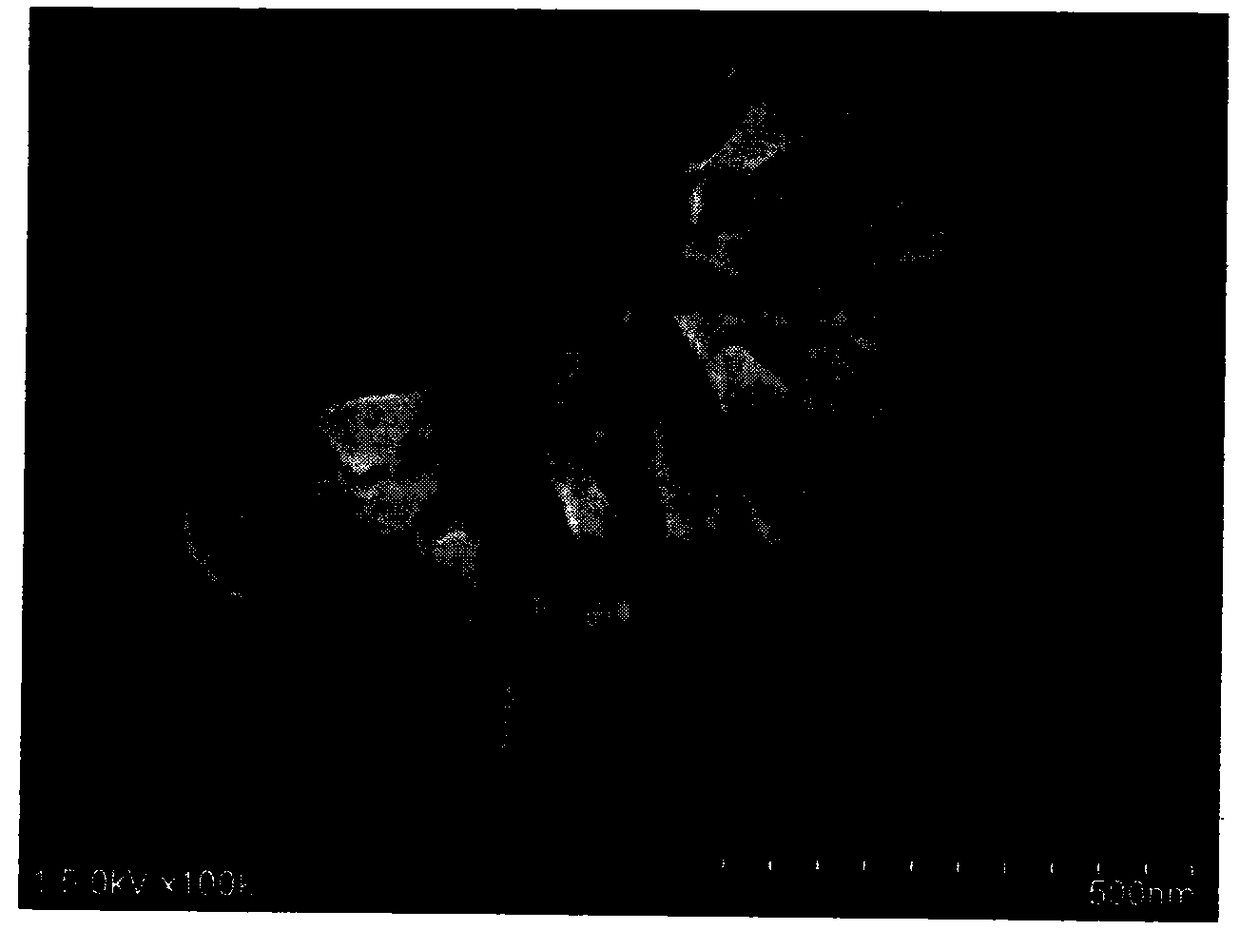

[0031]A carbon dioxide electrochemical reduction catalyst, which is composed of multi-level structure coral-shaped nano-tin oxide, the preparation method of the multi-level structure coral-shaped nano-tin oxide is a hydrothermal method, and the specific steps are: taking 12 mmol of urea and 2 mmol of The tin dichloride is mixed and dissolved in 50 mL of deionized water to form a uniform milky white solution, which is the catalyst precursor. The 80mL hydrothermal reaction kettle of the jacket was placed in an oven at 85°C for hydrothermal reaction for 12 hours, the obtained solid was washed with deionized water and absolute ethanol for several times to neutrality, centrifuged, and the obtained solid was placed in a After drying in an oven at 60 °C for 8 hours, a multi-level structure coral-like nano-tin stannous oxide (SnO) was obtained. 85-12 ) as a catalyst for the electrochemical reduction of carbon dioxide.

Embodiment 2

[0033] A carbon dioxide electrochemical reduction catalyst, which is composed of multi-level structure coral-shaped nano-tin oxide, the preparation method of the multi-level structure coral root-shaped nano-tin oxide is a hydrothermal method, and the specific steps are: taking 12 mmol of urea and 2mmol of tin dichloride is mixed and dissolved in 50mL of deionized water to form a uniform milky white solution, which is a catalyst precursor, and the catalyst precursor is placed in a reaction kettle, and the reaction kettle has a polytetrafluoroethylene liner, An 80mL hydrothermal reaction kettle with a stainless steel jacket was placed in an oven at 100°C for hydrothermal reaction for 12 hours, the obtained solid was washed with deionized water and absolute ethanol for several times to neutrality, centrifuged, and the obtained solid was separated by centrifugation. After drying in an oven at 60 °C for 8 hours, a multi-level structure coral-like nano-tin stannous oxide (SnO) was ob...

Embodiment 3

[0035] A carbon dioxide electrochemical reduction catalyst, which is composed of multi-level structure coral-shaped nano-tin oxide, the preparation method of the multi-level structure coral root-shaped nano-tin oxide is a hydrothermal method, and the specific steps are: taking 12 mmol of urea and 2mmol of tin dichloride is mixed and dissolved in 50mL of deionized water to form a uniform milky white solution, which is a catalyst precursor, and the catalyst precursor is placed in a reaction kettle, and the reaction kettle has a polytetrafluoroethylene liner, An 80mL hydrothermal reaction kettle with a stainless steel jacket was placed in an oven at 120°C for hydrothermal reaction for 12 hours, the obtained solid was washed several times to neutrality with deionized water and absolute ethanol, centrifuged, and the obtained solid was separated by centrifugation. After drying in an oven at 60 °C for 8 hours, a multi-level structure coral-like nano-tin stannous oxide (SnO) was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com