Horizontal and vertical type hydraulic regulating motor regulator

A technology for adjusting motors and regulators, which is applied in the direction of electrical components, electromechanical devices, and electric components. It can solve the problems of time-consuming and laborious replacement of motor installation belts and affect the normal production of oil fields, etc., and achieve fast and convenient motor installation and debugging. Ergonomic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

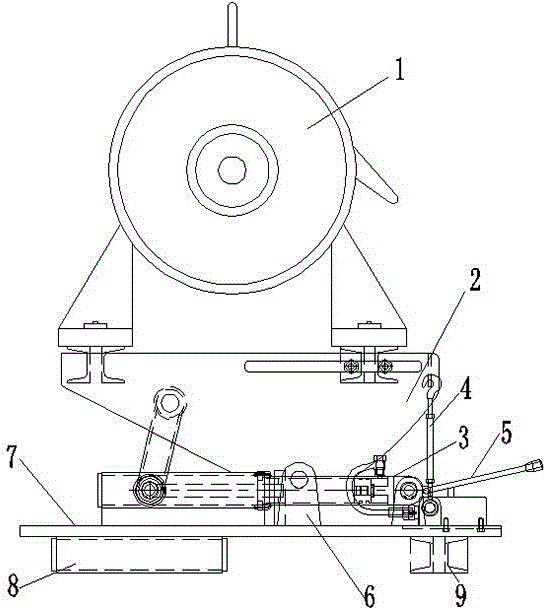

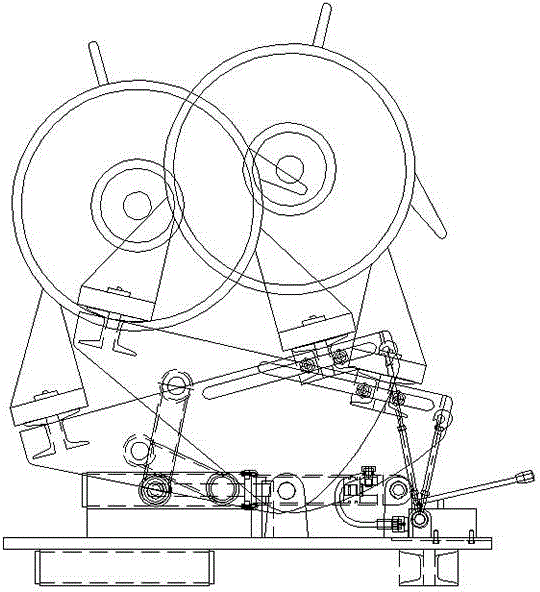

[0014] Example 1 Horizontal Motor Regulator

[0015] Such as figure 1 and figure 2 As shown, a motor regulator is mainly composed of a frame plate 2, a motor fixed base, a base plate 7 and a hydraulic rotation adjustment mechanism. The motor 1 is placed on the motor fixed base, and the motor fixed base is installed on the frame plate 2. The frame plate 2 The two sides are respectively connected to the bottom plate 7 through support ears 6. The hydraulic rotation adjustment mechanism includes a hydraulic cylinder 3 and an oil volume control valve 5. The oil volume control valve 5 is connected to the hydraulic cylinder 3. The hydraulic cylinder 3 is horizontally arranged at the bottom of the frame plate 2. The top end of the piston rod of the hydraulic cylinder 3 is connected to the front end of the frame plate 2, and a locking device 4 is provided between the other end of the frame plate 2 and the bottom plate 7. The longitudinal channel steel 8 and the transverse channel ste...

example 2

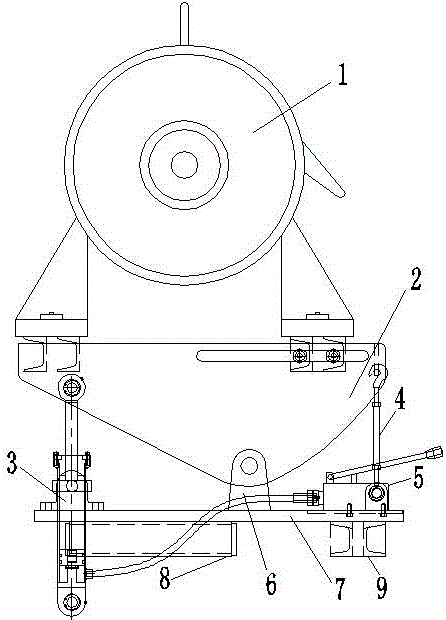

[0016] Example 2 Vertical Motor Regulator

[0017] Such as image 3 and Figure 4 As shown, a motor regulator is mainly composed of a frame plate 2, a motor fixed base, a base plate 7 and a hydraulic rotation adjustment mechanism. The motor 1 is placed on the motor fixed base, and the motor fixed base is installed on the frame plate 2. The frame plate 2 The two sides are respectively connected to the bottom plate 7 through support ears 6. The hydraulic rotation adjustment mechanism includes a hydraulic cylinder 3 and an oil volume control valve 5. The oil volume control valve 5 is connected to the hydraulic cylinder 3. The hydraulic cylinder 3 is vertically arranged at the bottom of the frame plate 2. , the top end of the piston rod of the hydraulic cylinder 3 is connected to the front end of the frame plate 2, a locking device 4 is provided between the other end of the frame plate 2 and the bottom plate 7, and the longitudinal channel steel 8 and the transverse channel steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com