Process for making confections

A sweet food and composition technology, applied in the confectionary industry, confectionery, application, etc., can solve the problem of time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

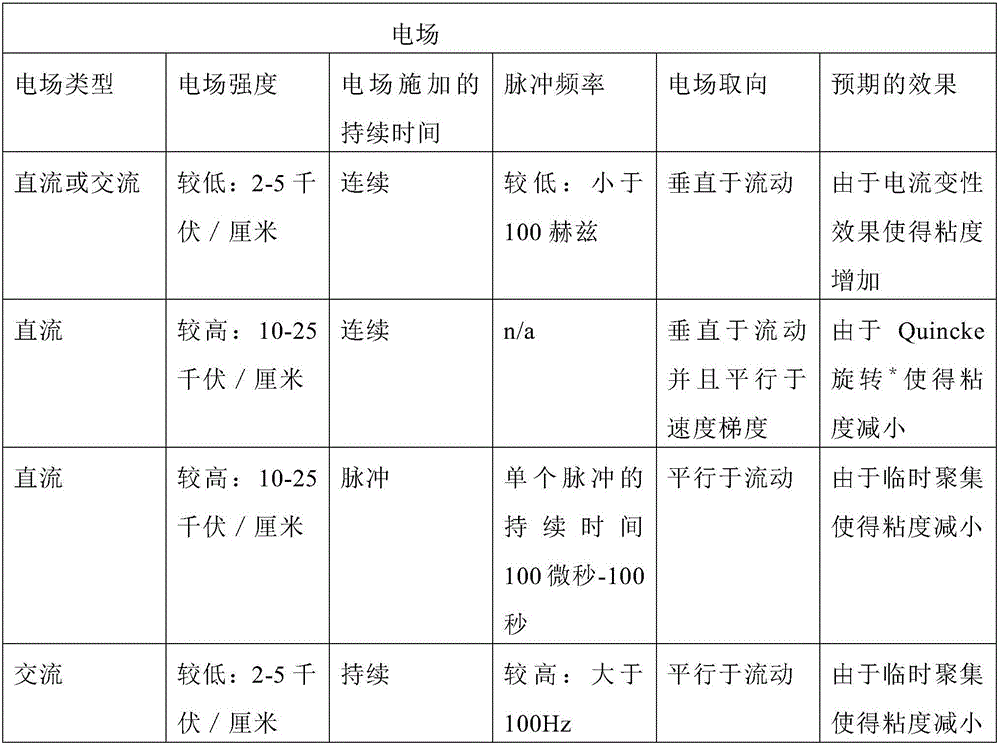

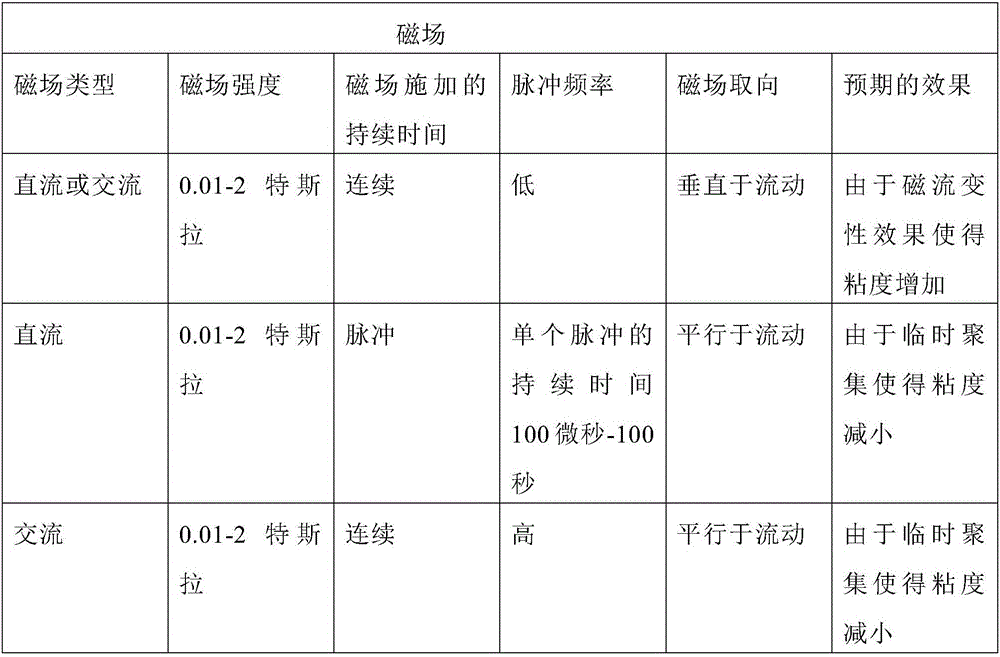

Method used

Image

Examples

Embodiment 1

[0066] A DC current electric field of 1 kV / cm was applied parallel to the flow direction to the melted chocolate for 60 s. Melted chocolate is obtained by melting commercial chocolate bars on a double boiler. The melted chocolate had an average particle size of 0.1 to 100 microns and a total protein content between 5% and 9% by weight, and an initial viscosity at ambient temperature (70°F, 21°C). After exposure to an electric field, the viscosity of the melted chocolate will decrease to about 20% of its initial value. After the electric field is removed, the viscosity will increase to its original viscosity over time. After about 30 minutes, the viscosity of the melted chocolate will increase to within about 5% of the original viscosity. The rate of viscosity increase is expected to drop substantially after the first 30 minute application period.

Embodiment 2

[0068] A DC current electric field of 1 kV / cm was applied perpendicular to the direction of flow to the melted chocolate for 60 s. Melted chocolate is obtained by melting commercial chocolate bars on a double boiler. The melted chocolate had an average particle size of 0.1 microns to 100 microns and a total protein content of between 2% and 9% by weight, and an initial viscosity at ambient temperature (70°F, 21°C). After exposure to an electric field, the viscosity of the melted chocolate will increase by about 20% of its initial value. After the electric field is removed, the viscosity will decrease to its original viscosity over time. After about 30 minutes, the viscosity of the melted chocolate will drop to within about 5% of the original viscosity. The rate of viscosity loss is expected to drop substantially after the first 30 minute application period.

example 3

[0070]A DC current electric field of 1 kV / cm was applied parallel to the direction of flow to the melted caramel for 60 s. Melted caramel is obtained by melting commercial caramel on a double boiler. The melted caramel had an average particle size of 0.1 microns to 100 microns and a total protein content between 2 weight percent and 9 weight percent, and an initial viscosity at ambient temperature (70°F, 21°C). After exposure to an electric field, the viscosity of the melted caramel will decrease to about 20% of its initial value. After the electric field is removed, the viscosity will increase to its original viscosity over time. After about 30 minutes, the viscosity of the melted caramel will increase to within about 5% of the original viscosity. The rate of viscosity increase is expected to drop substantially after the first 30 minute application period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com