Method for manufacturing semiconductor package and semiconductor package thereof

A manufacturing method, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as fracture, peeling, and the influence of electrical characteristics of semiconductor components, so as to improve adhesion and enhance Effects of joint strength and suppression of influence of electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0031] (semiconductor package)

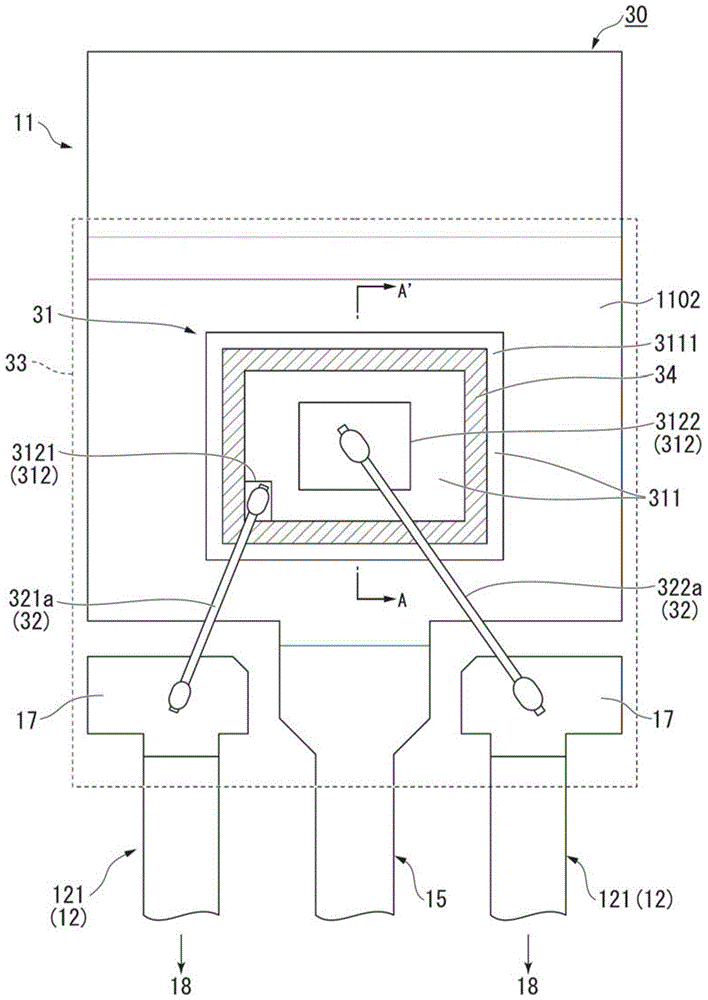

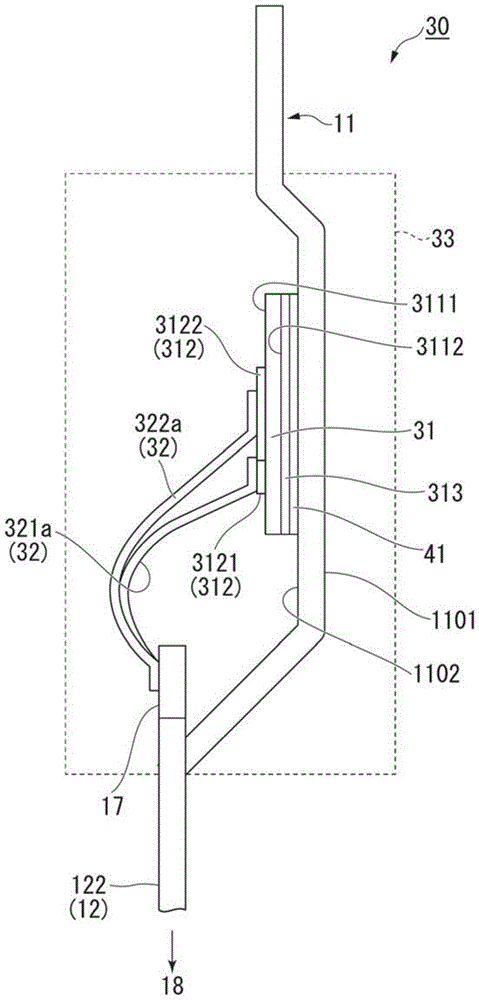

[0032] Below, will refer to Figure 1 to Figure 4 , the semiconductor package 30 according to this embodiment will be described. Such as figure 1 as well as figure 2 As shown, the semiconductor package 30 according to the present embodiment includes a die pad 11 , a semiconductor element 31 , a lead 12 , a suspension lead (Suspension Lead) portion 15 , a connection member 32 , and an encapsulation resin 33 .

[0033] The die pad 11 is a flat member for mounting the semiconductor element 31 . Such as figure 2 As shown, the chip pad 11 has: a first main surface 1101 , and a second main surface (upper surface) 1102 on the opposite side of the first main surface 1101 .

[0034] The semiconductor element 31 is bonded to the second main surface 1102 of the die pad 11 using a bonding member 41 such as solder or silver paste.

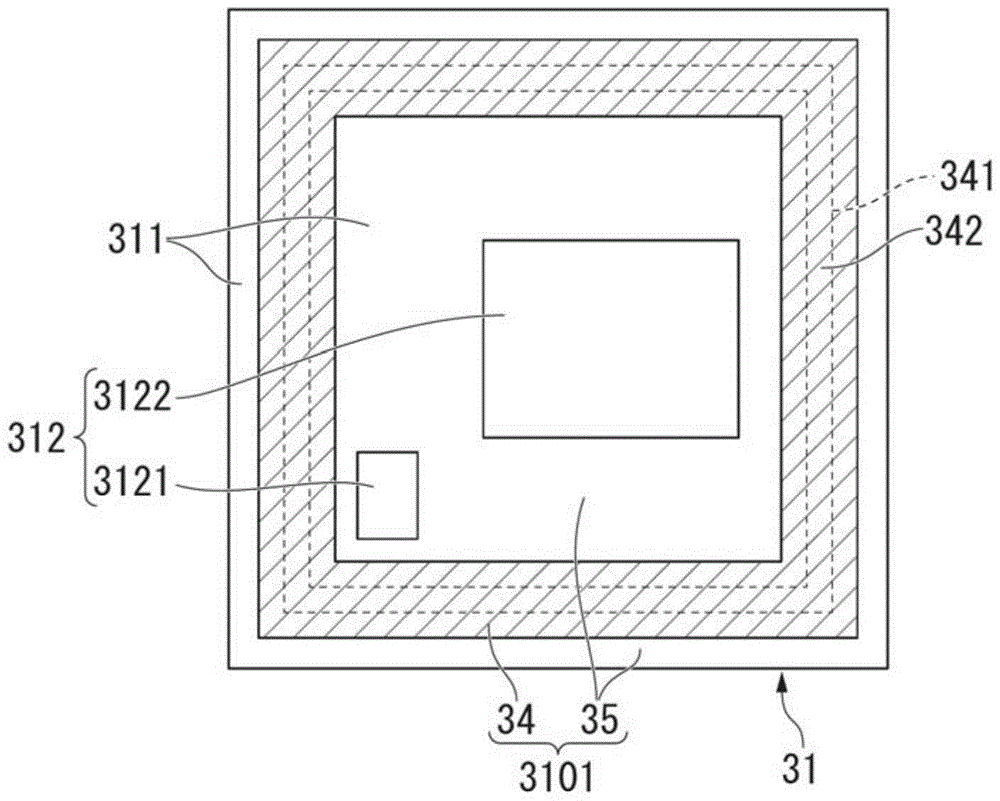

[0035] The semiconductor element 31 includes a base portion 311 . The base portion 311 is a semiconductor having a re...

no. 2 approach

[0091] Below, will refer to Figure 7 , the semiconductor package 30b according to this embodiment will be described. Below, yes and figure 1 Components that are the same as in FIG. 6 are denoted by the same symbols and descriptions thereof are omitted.

[0092] Such as Figure 7As shown, in this embodiment, the connecting member 32 is not a bonding wire, but a clip-type (Clip) terminal. In this point, it is different from the first embodiment.

[0093] The clip-on terminal is a long plate-shaped connecting member, which is formed by bending a conductive plate. One end surface of the clip terminal is bonded to the surface of the first end portion 17 of the lead wire 12 via a bonding member such as solder or silver paste. The surface of the other end of the clip terminal is bonded to the surface of the electrode portion 312 via a bonding member such as solder or silver paste.

[0094] The clip-on terminal includes, for example, a first clip-on terminal (not shown) and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com