A kind of processing method of black hair tea

A processing method and technology for black hair tea, applied in the processing field of black hair tea, can solve the problems of rough appearance, bitter taste, poor aroma, etc., and achieve the effect of reddish-brown color, mellow and smooth taste, and orange-red and translucent soup color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] This embodiment is used to illustrate the black hair tea processing method of the present invention.

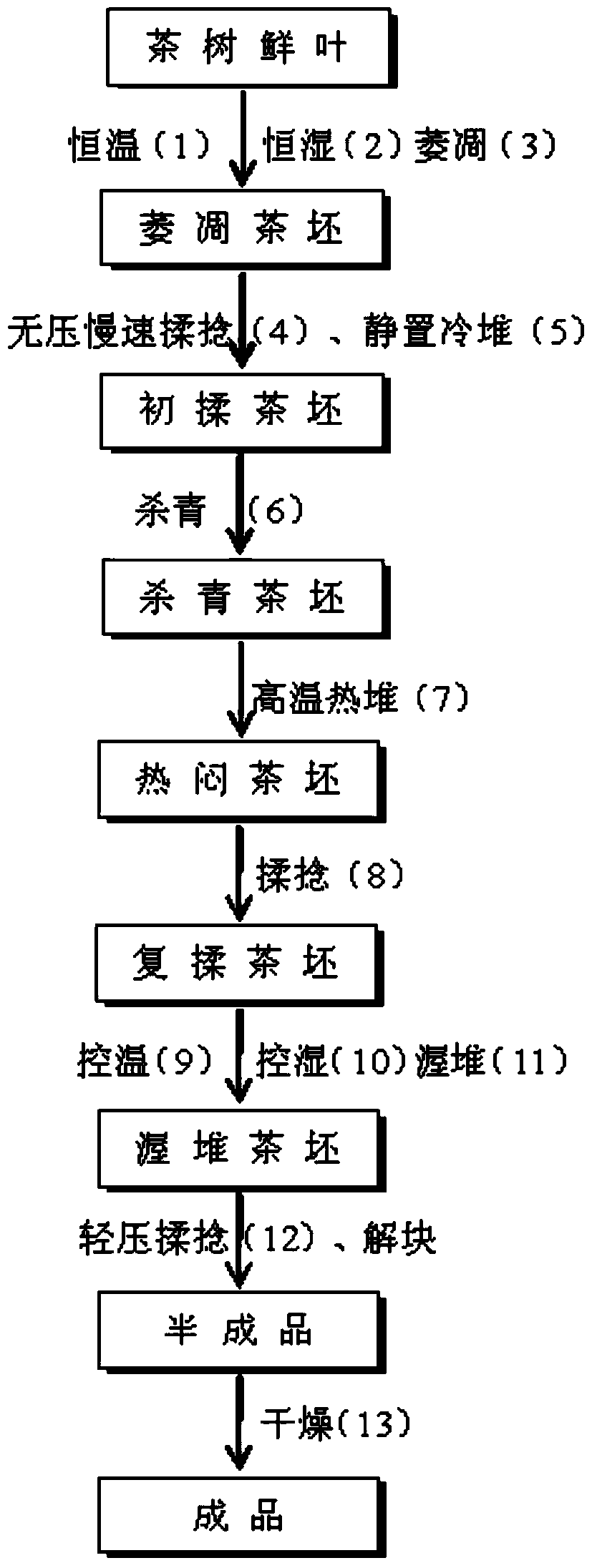

[0046] Such as figure 1 As shown, the method is specifically:

[0047]Take the fresh leaves of one-bud two-leaf and three-leaf tea as processing raw materials, place them in a withering room with a temperature of 30°C (1) and a relative humidity of 75% (2) to wither for 6-8 hours (3), collect the withered leaves until rolling The machine kneaded for 30 minutes without pressurization (4), and at the same time, the speed of the kneading machine was reduced through the frequency converter, and the kneading speed was 30r / min. 260°C roller degreening machine for 4-6 minutes (6), after the degreening is completed, directly pack it into an airtight plastic bag and seal it, place it in a withering room at 40°C for 2 hours (7), take out the tea leaves after the heat is over Cool down quickly and disperse. After the leaf temperature drops to room temperature, put it in a knea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com