Fragrant egg drop yellow tea processing method

A processing method and a flower-scented technology, applied in the processing field of egg-flower-flavored yellow tea, can solve the adjustment of tea product structure that is not conducive to yellow tea getting rid of difficulties, and the research and development of yellow tea processing technology and product research and development are weak, and cannot be widely promoted in time. Market and other issues, to achieve the effect of rich health care, rich content and pleasant aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

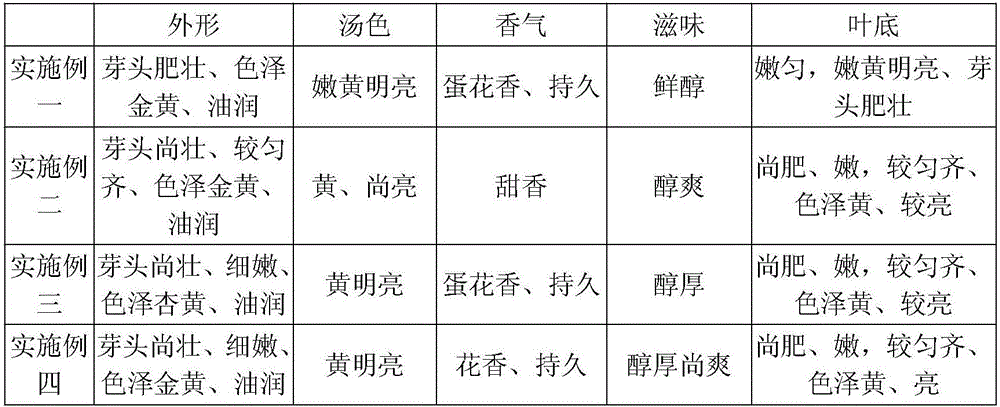

Examples

Embodiment 1

[0030] (1) Harvesting of raw materials: in mid-March, the fresh leaves of tea trees with one bud and two leaves are picked as raw materials;

[0031] (2) Greening: In the greening process, a new process of combining natural greening alone, a separate greening trough, natural greening and greening trough can be used to carry out natural greening on the fresh leaves At the same time, place the above-mentioned picked tea leaves on white cotton cloth, and spread them evenly in a cool and ventilated place indoors, with a thickness of 1cm, and the spreading time is 20 minutes in sunny days and 1 hour in cloudy and rainy days;

[0032] (3) Finishing: put the green tea leaves into the drum continuous greening machine for finishing, the pot temperature at the entrance of the drum continuous greening machine is set to 200°C, the pot temperature at the exit is 180°C, and the rotating speed is 50r / min , set the average time from the import to the export of the green tea after spreading to...

Embodiment 2

[0038] (1) Harvesting of raw materials: picking fresh leaves of tea trees with one bud and two leaves in the first ten days of May as raw materials;

[0039] (2) Greening: In the greening process, a new process of combining natural greening alone, a separate greening trough, natural greening and greening trough can be used to carry out natural greening on the fresh leaves Place the above-mentioned picked tea leaves on white cotton cloth, and spread them evenly in a cool and ventilated place indoors, with a thickness of 1.5cm, and the spreading time is 30 minutes in sunny days and 1 hour in cloudy and rainy days;

[0040](3) Finishing: Put the green tea leaves into the drum continuous greening machine for finishing. The pot temperature at the entrance of the drum continuous greening machine is set to 220°C, the pot temperature at the exit is 200°C, and the rotating speed is 60r / min , set the average time from the import to the export of the green tea after spreading to 6 minute...

Embodiment 3

[0046] (1) Harvesting of raw materials: in mid-April, the fresh leaves of tea trees with one bud and two leaves are picked as raw materials;

[0047] (2) Greening: In the greening process, a new process of combining natural greening alone, a separate greening trough, natural greening and greening trough can be used to carry out natural greening on the fresh leaves At the same time, place the above-mentioned picked tea leaves on white cotton cloth, and spread them evenly in a cool and ventilated place indoors, with a thickness of 1.2cm, and the spreading time is 25 minutes in sunny days and 1 hour in cloudy and rainy days;

[0048] (3) Finishing: Put the green tea leaves into the drum continuous greening machine for finishing. The pot temperature at the inlet of the drum continuous greening machine is set to 210°C, the pot temperature at the exit is 190°C, and the rotating speed is 55r / min , set the average time from the import to the export of the green tea after spreading to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com