Upper grabbing line tensioning device

A technology for tensioning device and shoe upper, applied in shoe last, footwear, application and other directions, can solve the problems of high labor intensity of workers, falling off, shoe last displacement, etc., and achieves compact structure, reasonable structure layout, and reduced floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

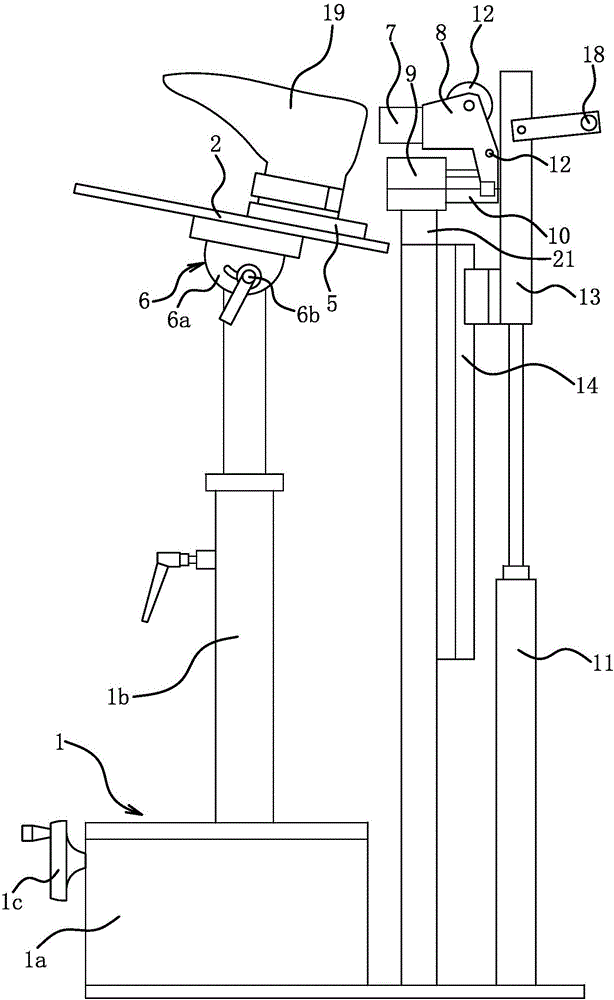

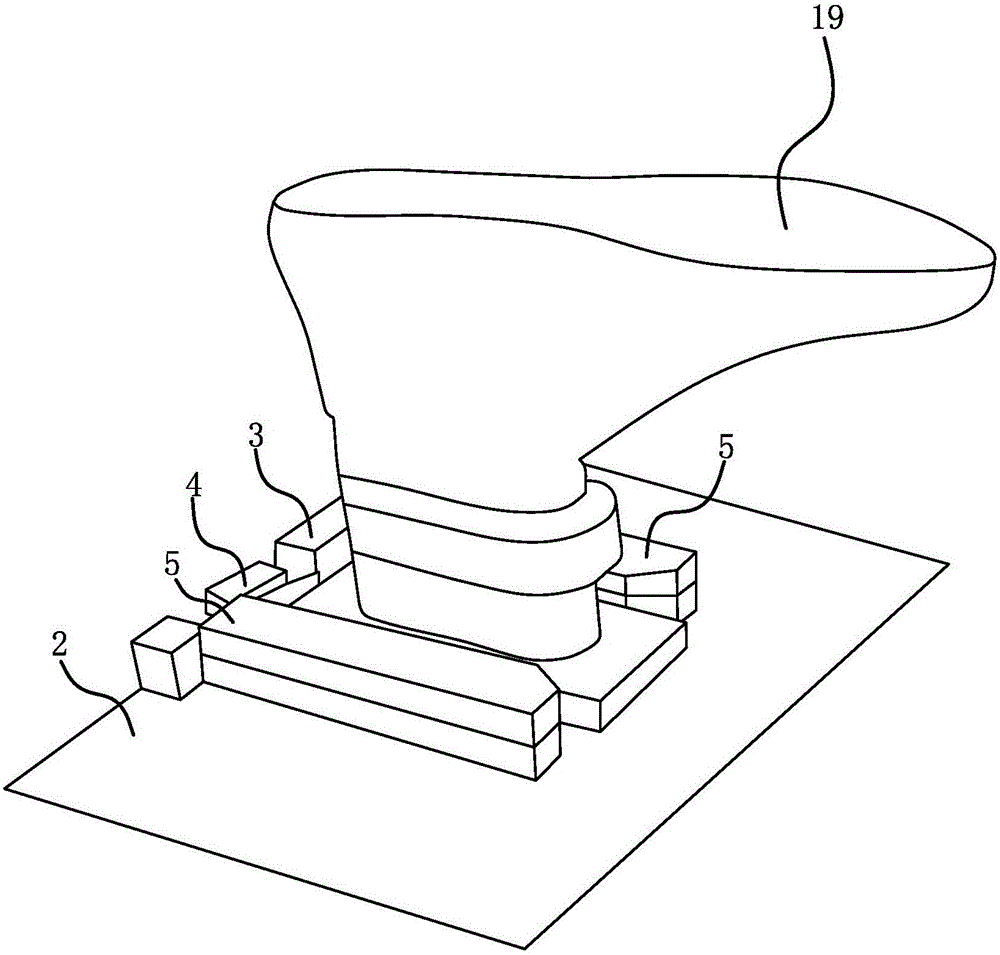

[0015] Such as Figure 1 to Figure 3 As shown, the shoe upper grasping upper line tensioning device includes a frame 1, a fixing seat 2 and a traction structure.

[0016] The frame 1 includes a base 1a and a telescopic rod 1b that can be adjusted in length vertically. The lower end of the telescopic rod 1b is connected to the base 1a through a first linear guide assembly, and the guiding direction of the first linear guide assembly is front and rear. . A locking structure for locking the telescopic rod 1b on the base 1a is also provided between the base 1a and the telescopic rod 1b. The locking structure includes a first screw nut assembly, the screw rod is rotationally connected to the base 1a, the screw nut is fixedly connected to the telescopic rod 1b, and a handwheel 1c is fixedly connected to the screw rod. According to the actual situation, the locking structure can adopt the following structure. The locking structure includes a locking bolt arranged at the bottom of t...

Embodiment 2

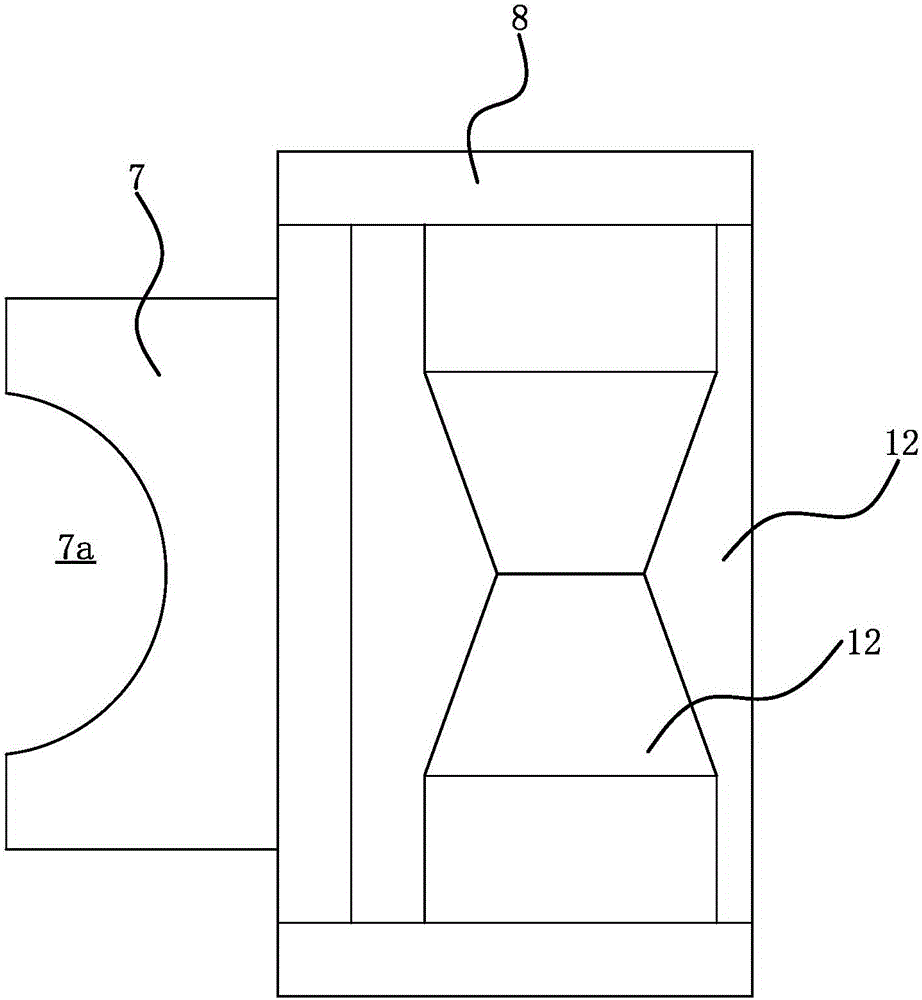

[0027] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described repeatedly, only the differences will be described. The difference lies in: the front side of the fixing seat 2 is provided with a shoe upper and heel pressure piece 7 , The upper heel pressure piece 7 is fixed on the bracket 8 . The shoe upper heel pressure piece 7 is a pressure block made of flexible material, and the shoe upper heel pressure piece 7 of the pressure piece has a groove 7a corresponding to the shoe upper heel, so by increasing the contact area, the shoe upper pressure is significantly improved. Firmness. The flexible material is rubber or plastic. According to the actual situation, the upper heel pressing part 7 can be replaced by the following structure, the upper heel pressing part 7 is a pressing sheet made of spring steel. The position of the upper heel pressure member 7 is opposite to the position of the ...

Embodiment 3

[0030]The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described, and the difference lies in the direct fixed connection between the lower end of the telescopic rod 1b and the base 1a .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com