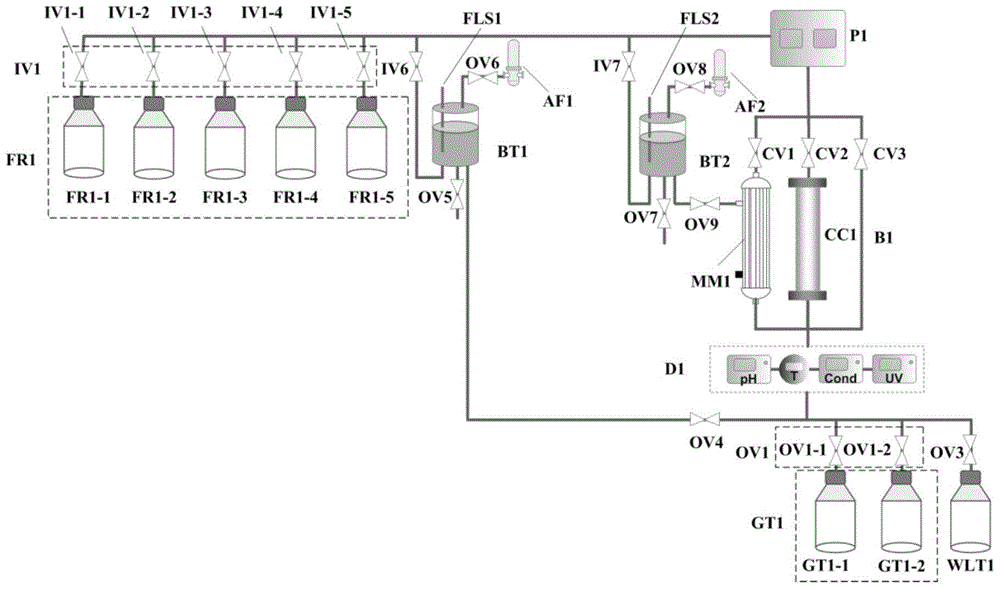

Column chromatography and membrane filtration integration system

An integrated system and column chromatography technology, applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of high cost, achieve cost saving, avoid pollution and inactivation, and shorten the process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

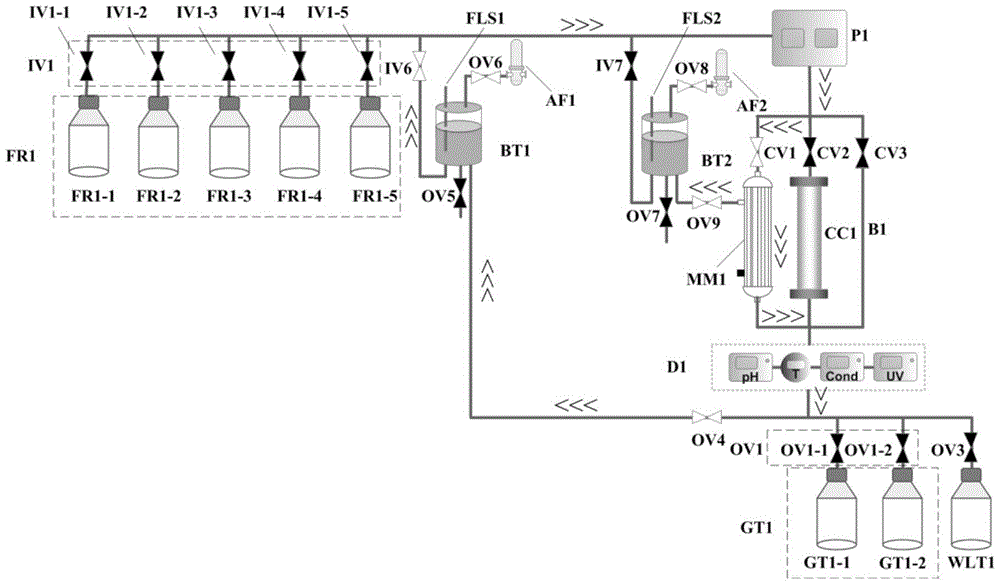

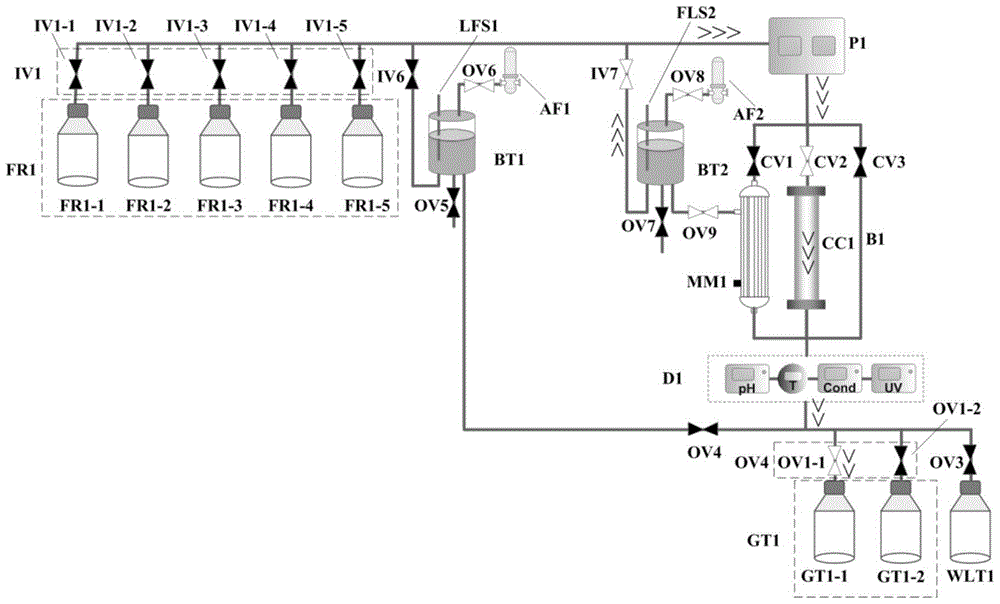

[0057] Such as figure 2 Shows the flow path connection where the mobile phase is first purified through the membrane module.

[0058] 1) Add the raw materials to be separated into the first storage tank FR1-1, open the first storage tank inlet valve IV1, the membrane module selection valve CV1, the first loop outlet valve OV4, the first exhaust outlet valve OV6, The second exhaust outlet valve OV8, the second loop outlet valve OV9, pump P1 quantitative raw material liquid, through the membrane module MM1 for sample filtration, the concentrated liquid enters the first liquid collection tank BT1, the permeate enters the second liquid collection tank BT2.

[0059] 2) After the liquid in the liquid collecting tank reaches a certain amount, close the inlet valve IV1-1 of the first liquid storage tank, open the inlet valve IV6 of the first liquid collecting tank, and carry out further circulation, concentration and filtration of the concentrated liquid. The final concentrate is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com