A filter material for air purification and preparation method thereof

A filter material and air purification technology, applied in chemical instruments and methods, filtration separation, membrane filters, etc., can solve the problems of complex air filtration products, inability to filter PM2.5, high cost, etc., and achieve significant purification. The effect, stable performance and excellent, easy to industrialized production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

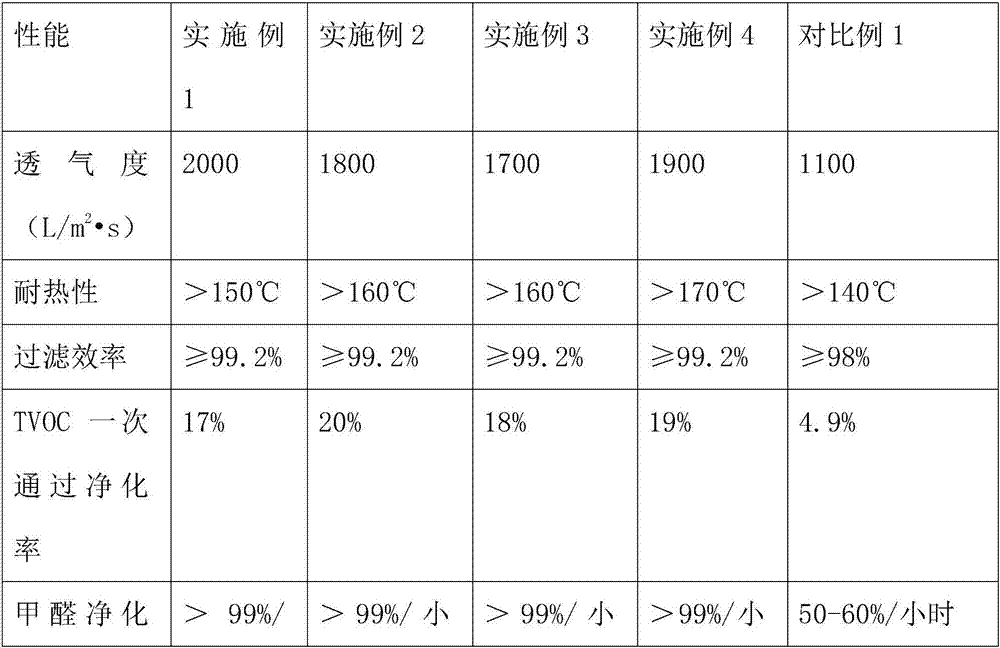

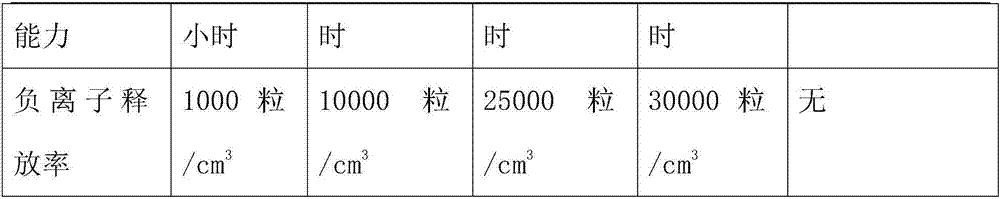

Examples

Embodiment 1

[0047] A filter material for air purification, prepared by the following method:

[0048] Take polypropylene staple fiber with a fiber fineness of 6D and a fiber length of 20mm and a bamboo fiber with a fiber fineness of 2D and a fiber length of 10mm, mix the polypropylene staple fiber and the bamboo fiber uniformly, and then perform coarse opening and fineness in sequence. Open

[0049] The finely opened and loosened fibers are sent to a carding machine for carding, and the carded fibers are sent to the needle punching machine. The needle punching machine implants needles at a speed of 350 times per minute and a density of 2000 per square meter to make polypropylene staple fibers The composite bamboo fiber filter layer is prepared by mixing it with bamboo raw fiber. In the composite bamboo fiber filter layer, the weight percentage of polypropylene short fiber is 20%, and the weight percentage of bamboo fiber is 80%. The obtained composite The thickness of the bamboo fiber filter ...

Embodiment 2

[0056] A filter material for air purification, prepared by the following method:

[0057] Take polypropylene short fiber with a fiber fineness of 7D and a fiber length of 50mm and a bamboo fiber with a fiber fineness of 4D and a fiber length of 50mm, mix the polypropylene short fiber and the bamboo raw fiber uniformly, and then perform coarse opening and finishing in turn Open

[0058] The finely opened fibers are sent to a carding machine for carding, and the carded fibers are sent to the needle punching machine. The needle punching machine implants needles at a speed of 400 times per minute and a density of 3500 per square meter to make polypropylene staple fibers The composite bamboo fiber filter layer is prepared by mixing it with bamboo raw fiber. In the composite bamboo fiber filter layer, the weight percentage of polypropylene short fiber is 30%, and the weight percentage of bamboo fiber is 70%. The obtained composite The thickness of the bamboo fiber filter layer is 1mm, a...

Embodiment 3

[0065] A filter material for air purification, prepared by the following method:

[0066] Take polypropylene short fiber with a fiber fineness of 7D and a fiber length of 80mm and a bamboo fiber with a fiber fineness of 8D and a fiber length of 80mm, mix the polypropylene short fiber and the bamboo fiber uniformly, and then proceed to coarse opening and finishing in turn Open

[0067] The finely opened fibers are sent to a carding machine for carding, and the carded fibers are sent to the needle punching machine. The needle punching machine implants needles at a speed of 450 times per minute and a density of 5000 per square meter to make polypropylene staple fibers The composite bamboo fiber filter layer is prepared by mixing it with bamboo raw fiber. In the composite bamboo fiber filter layer, the weight percentage of polypropylene short fiber is 50%, and the weight percentage of bamboo fiber is 50%. The obtained composite The thickness of the bamboo fiber filter layer is 3mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com