Micro-fluidic chip for generating spherical microbubbles

A microfluidic chip and microbubble technology, applied in the field of fluid machinery, can solve the problems of lengthy, cumbersome, difficult operation, etc., and achieve the effect of stable production process and wide controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

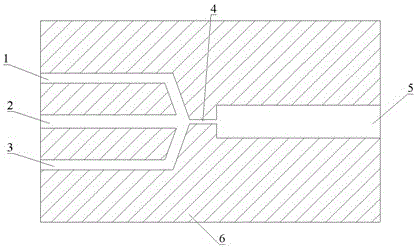

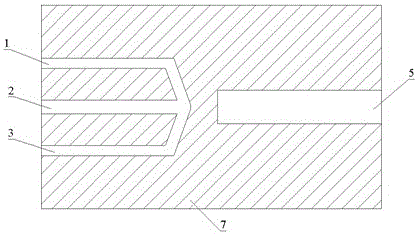

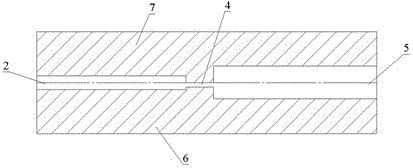

[0016] like Figure 1-3 As shown, taking PDMS as an example of a microfluidic chip made of material, the specific embodiment of the present invention is:

[0017] Microfluidic chip, rectangular parallelepiped, 40mm long, 20mm wide, 5mm high, formed by bonding the first chip 6 and the second chip 7, microchannels are etched on the surface of the chip using photoetching technology, the first chip includes liquid injection Channels 1 and 3, channel width 30 μm, depth 20 μm, gas injection channel 2, channel width 40 μm, depth 20 μm, bevel design at the junction of liquid channels 1, 3 and gas channel 2, the included angle is 70°, microbubble generation channel 4 , the channel length is 40 μm, the channel width is 10 μm, and the depth is 10 μm. The side section of the microbubble generation channel can form a square with a side length of 10 μm. Microbubble output channel 5, the channel width is 100 μm, and the depth is 40 μm. The liquid channel, the gas channel and the microbubble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com