A high-strength metal mesh automatic edge-sealing machine, system and use method

A technology of metal mesh and automatic locking, which is applied to the online network, applications, household appliances, etc., can solve the problems that the quality of manual seaming cannot meet the requirements, the manual seaming is difficult to achieve, and the quality of seaming is different, so as to achieve stable and reliable machine operation , Ingenious structural design, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

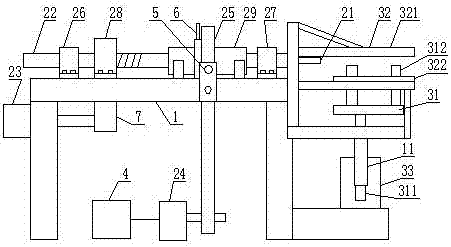

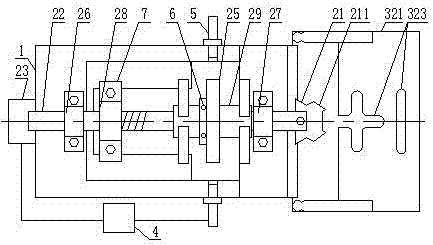

[0050] Such as figure 1 and figure 2 As shown, a high-strength metal mesh automatic seaming machine includes a frame 1, a seaming twisting mechanism, a positioning mechanism and a control system 4.

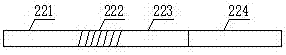

[0051] The locking and twisting mechanism is used to realize the feeding and twisting action of the locking head 21, and it includes the locking head 21, the rotating shaft 22, the cylinder 23, the power mechanism B24 and the transmission wheel 25. Such as image 3 As shown, the rotating shaft 22 includes a first circular shaft section 221 , a threaded section 222 , a square shaft section 223 and a second circular shaft section 224 arranged axially from left to right; Shaft sleeve A26, shaft sleeve C28, shaft sleeve D29 and shaft sleeve B27 are sequentially arranged from left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com