Manufacturing method for part with capillary-structure pipe embedded therein

A capillary structure and manufacturing method technology, applied in the field of parts manufacturing, can solve problems such as difficult to improve the heat transfer limit of parts, limit the development of microelectronic components, and difficult to handle tiny parts, etc., to achieve simple and fast manufacturing methods, speed up heat conduction efficiency, The effect of less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

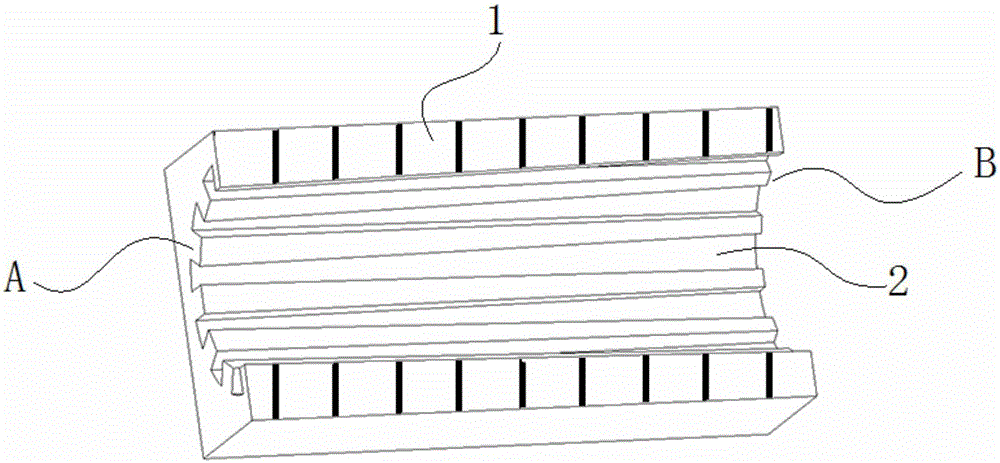

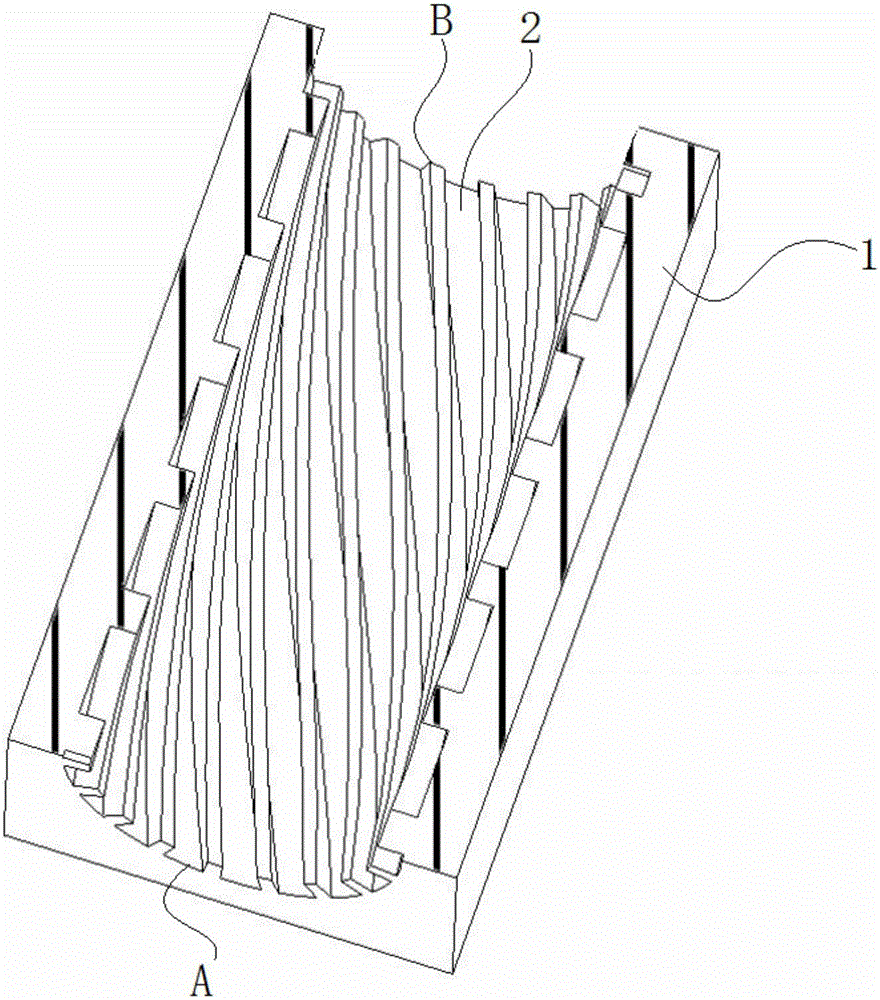

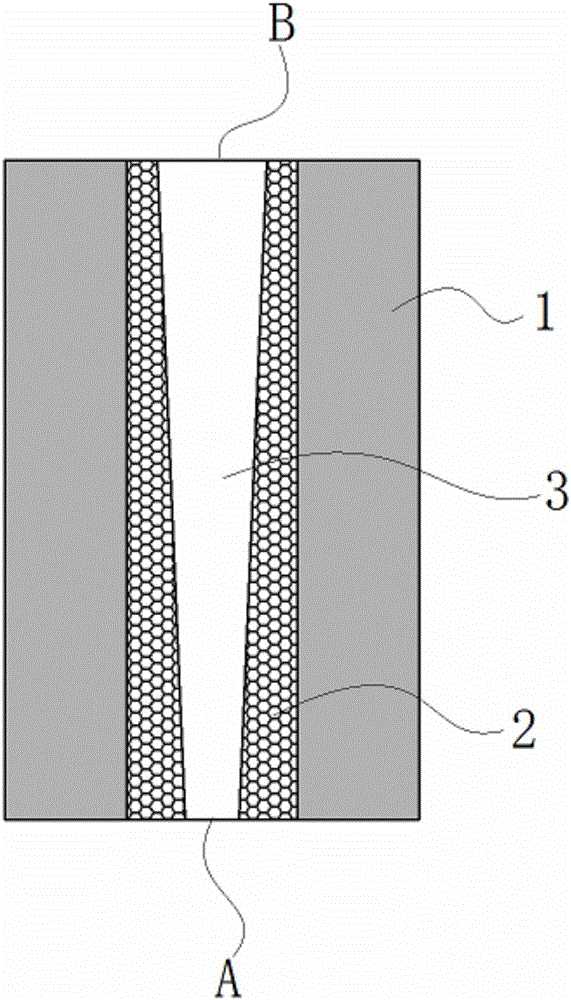

[0040] see Figure 2 to Figure 5 , at least one hollow pipe 3 is distributed inside the part 1 to be manufactured; the two outlets of the hollow pipe 3 are on the two surfaces of the part 1 respectively. One end is denoted as A terminal, and the other end is denoted as B terminal. In the embodiment, the end A is the end close to the heat source, and the end B is the end far away from the heat source.

[0041] see figure 1 or figure 2 There are several grooves 2 on the side wall of the hollow pipe. In an embodiment, the groove 2 can be like figure 1 In that way, extending from end A to end B in a straight line can also be done like figure 2 That way, it extends helically from the A end to the B end.

[0042] During manufacture, the following steps are included:

[0043] 1) Draw the model of the part 1 to be manufactured; in the model, the outlets of the A end and the B end of the pipeline 2 can be both open, and one of them can also be closed.

[0044] 2) import the m...

Embodiment 2

[0050] The main structure of this embodiment is the same as that of Embodiment 1. Further, the width of the trench 2 is gradual, that is, gradually widens from the A end to the B end.

Embodiment 3

[0052] The main structure of this embodiment is the same as that of Embodiment 1. Further, the cross section of the solid part between any two grooves 2 is rectangular, triangular, trapezoidal or circular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com