Semi-automatic spot welding machine

A technology of automatic spot welding and welding machine, applied in the direction of cleaning welding torch, welding rod characteristics, welding equipment, etc., can solve the problems of low degree of machine automation, low welding efficiency, single function, etc., to achieve convenient and fast welding process, improve welding speed and Efficient, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

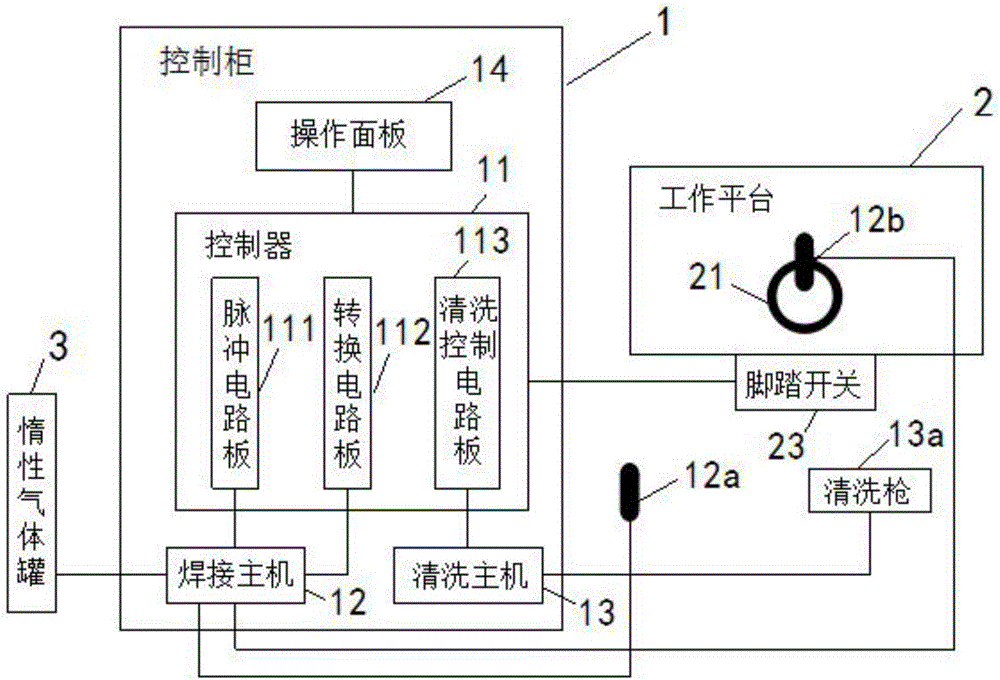

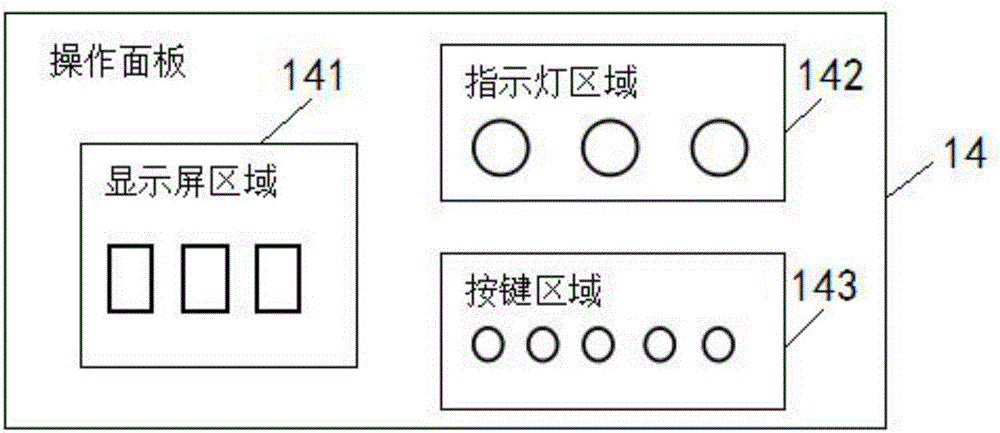

[0025] The invention provides a semi-automatic spot welding machine, such as figure 1 As shown, the semi-automatic spot welding machine includes a control cabinet 1 and a working platform 2, and the control cabinet 1 is provided with a controller 11, a welding host 12 and a cleaning host 13, and the controller 11 is used to control the welding host 12 and the cleaning host 13 working;

[0026] The welding host 12 is connected with a movable welding torch 12a and a fixed welding torch 12b. The working platform 2 is provided with a rotatable pad 21. The main body of the fixed welding torch 12b is fixedly installed under the pad 21 by a fixing device. The gun of the fixed welding torch 12b The head protrudes from the welding pad 21, and the fixing device includes three adjustment screws, which are respectively used to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com