Electromagnetic train

An electromagnetic and train technology, applied in the field of trains, can solve the problems of restricting the popularization and use of maglev trains, large power consumption of levitation magnets, low vehicle payloads, etc., and achieves the effects of reduced dead weight, light dead weight and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

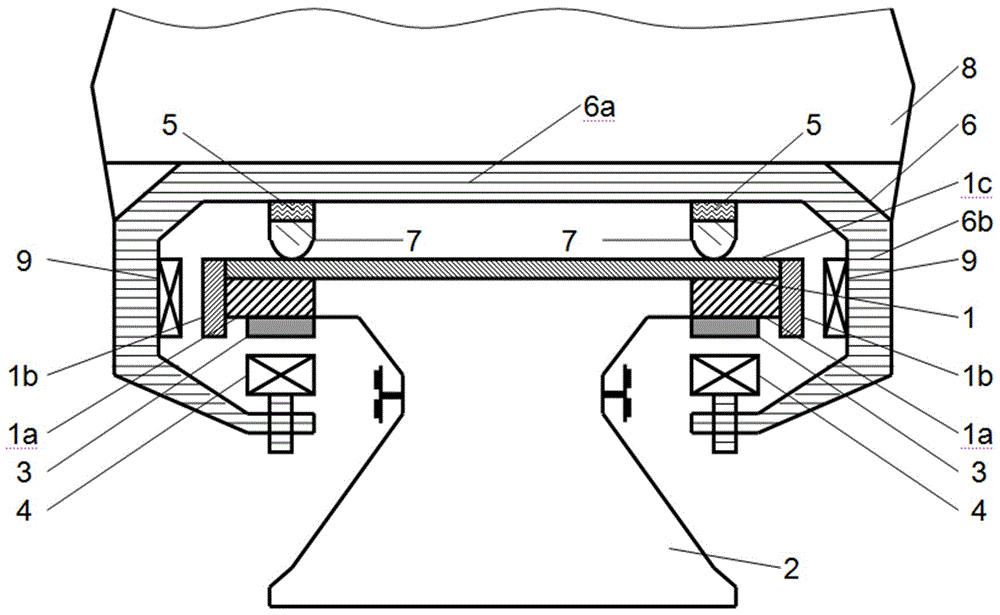

[0013] as attached figure 1 Shown, the line track of electromagnetic train of the present invention comprises track 1, reinforced concrete pier foundation 2, and its effect is to guide train advancing direction, bear train load simultaneously and pass it to foundation. Track 1 is the upper structure of the line, including stator surface 1a (for suspension), side guide rail surface 1b (for controlling the direction of the train), sliding rail surface 1c (for supporting the train) and its fixed accessories; reinforced concrete pier Foundation 2 is the substructure of the line.

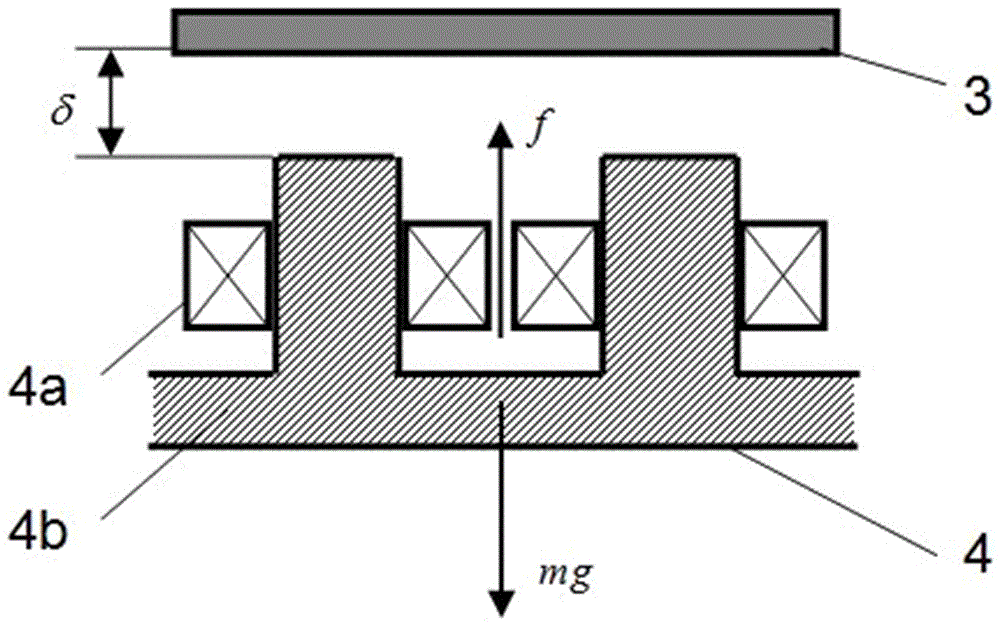

[0014] The driving system of the electromagnetic train includes a long stator 3, which is laid on both sides of the track along the entire line, and forms a long stator linear synchronous motor with the rotor 4 installed on the vehicle 8, which is used for both driving and braking. Its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com