A sealed liquid storage tank with an elastic liner compensating device

A compensation device and liquid storage tank technology, applied in the field of sealed liquid storage tanks, can solve the problems of high manufacturing, use and maintenance costs, oxidation reactions, other chemical reactions, deterioration, deterioration and other problems, so as to reduce work intensity and work. Time, oxidation prevention, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

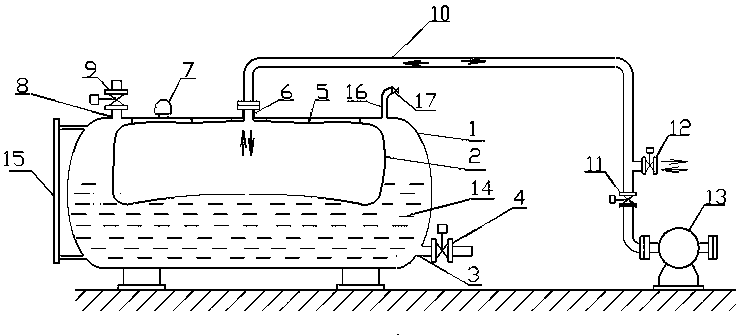

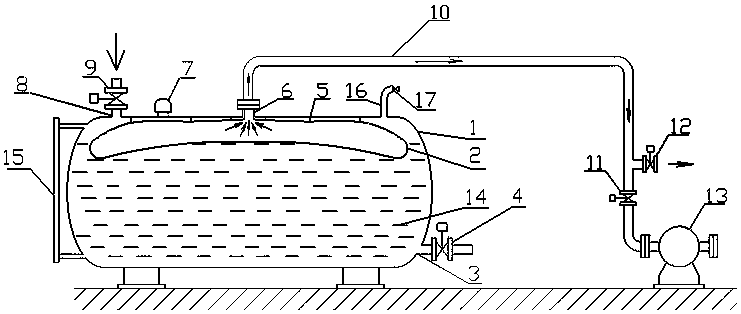

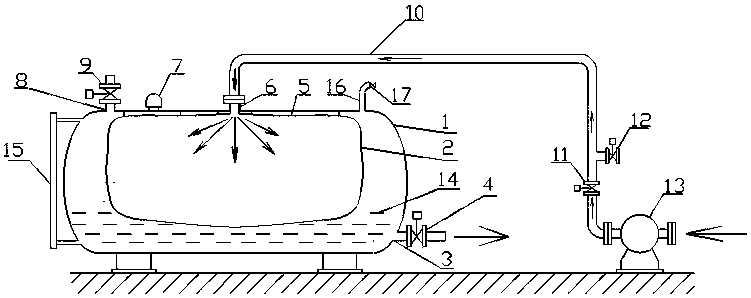

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Please refer to figure 1 , the present embodiment provides a sealed liquid storage tank with an elastic liner compensation device, including a sealed liquid storage tank 1, characterized in that: the top of the sealed liquid storage tank 1 is provided with a liquid inlet 8, and on the top of the liquid inlet 8 A liquid inlet solenoid valve 9 is provided; a liquid outlet 3 is provided at the bottom of the sealed liquid storage tank 1, and a liquid outlet solenoid valve 4 is arranged on the liquid outlet 3; an elastic liner 2 is arranged inside the sealed liquid storage tank 1, and the sealed storage tank 1 The top of the liquid tank 1 is also provided with a vent pipe 16, an air flow balance pipe 10 and an electric contact pressure gauge (not shown in the figure) for detecting the internal air pressure of the sealed liquid storage tank 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com