A robotic gripper

A robot fixture and mounting plate technology, which is applied in the directions of separating objects, supplying objects, sending objects, etc., can solve the problems of unpacking, unpacking, and manual handling, and achieves reasonable structure and size, reduces labor intensity, and improves the level of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

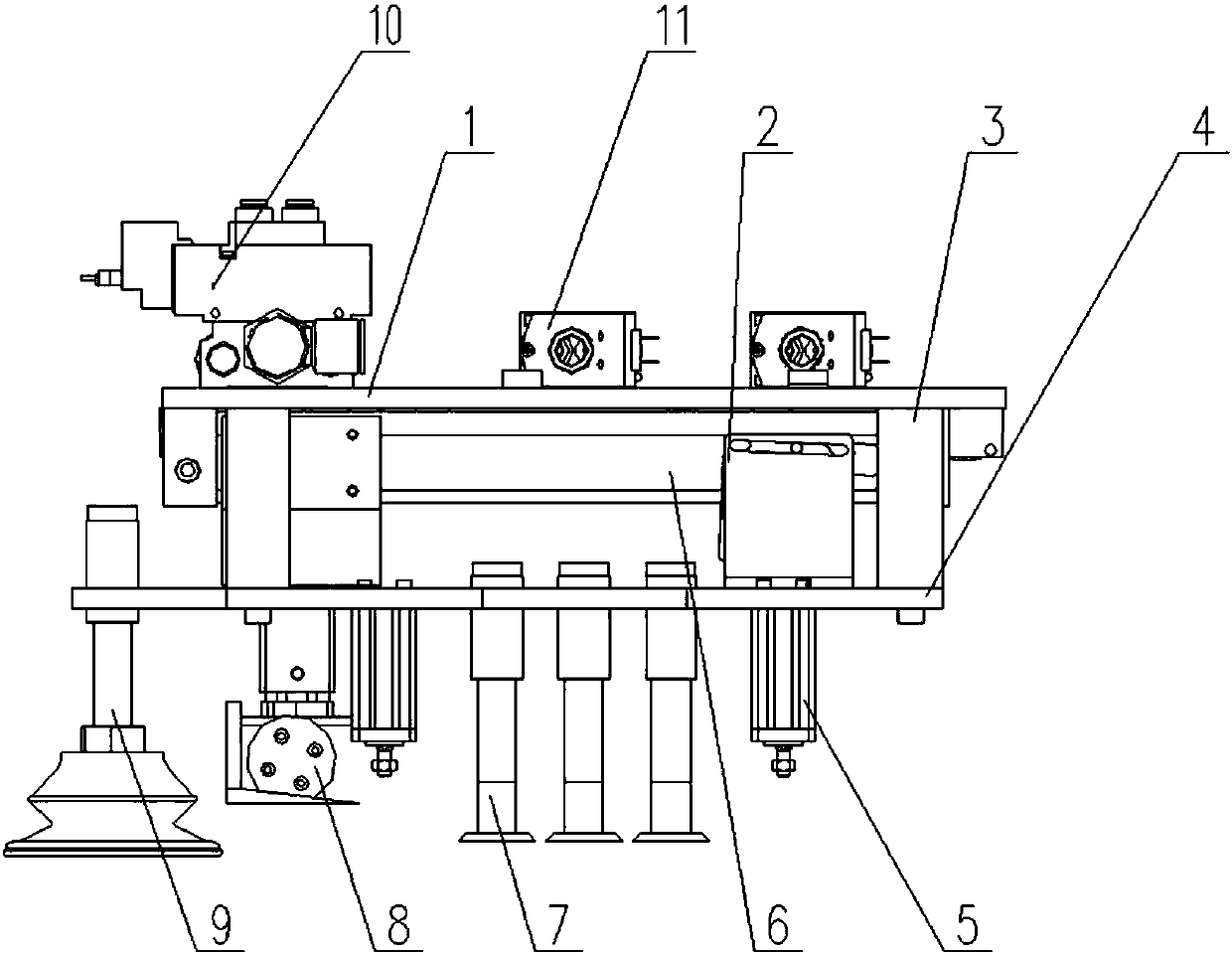

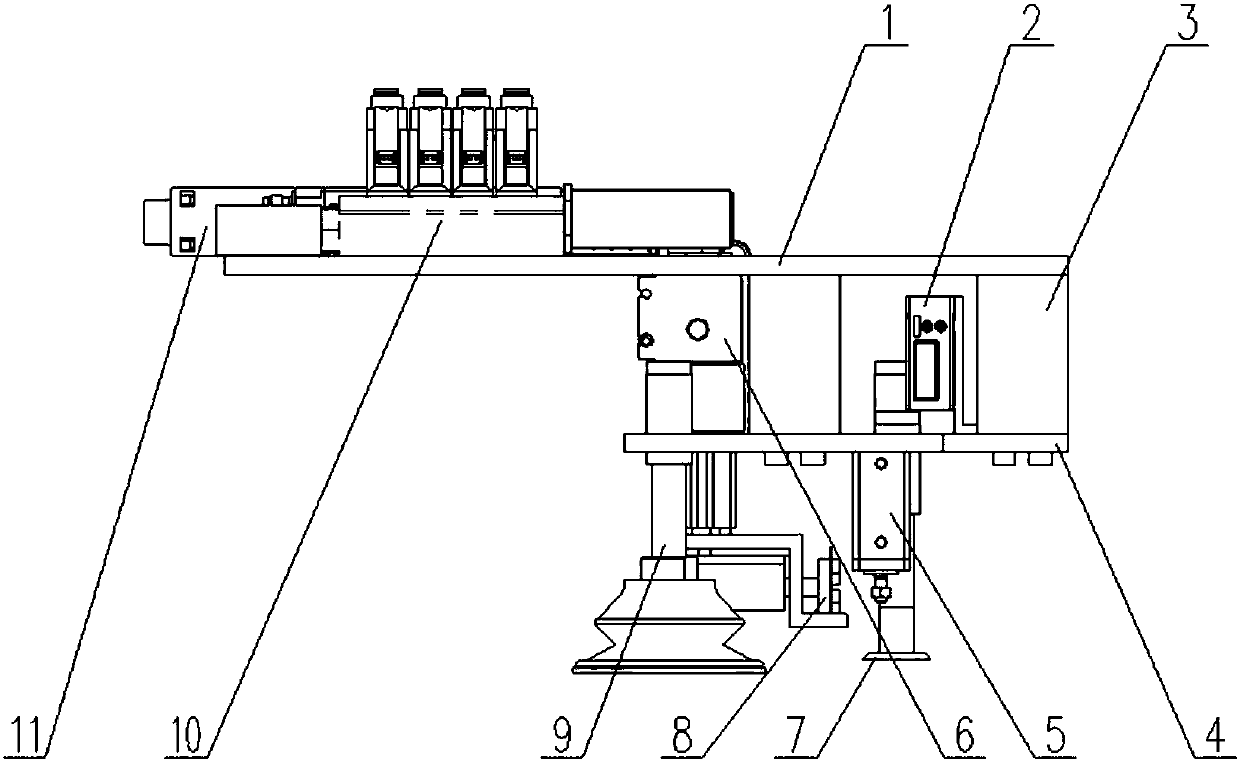

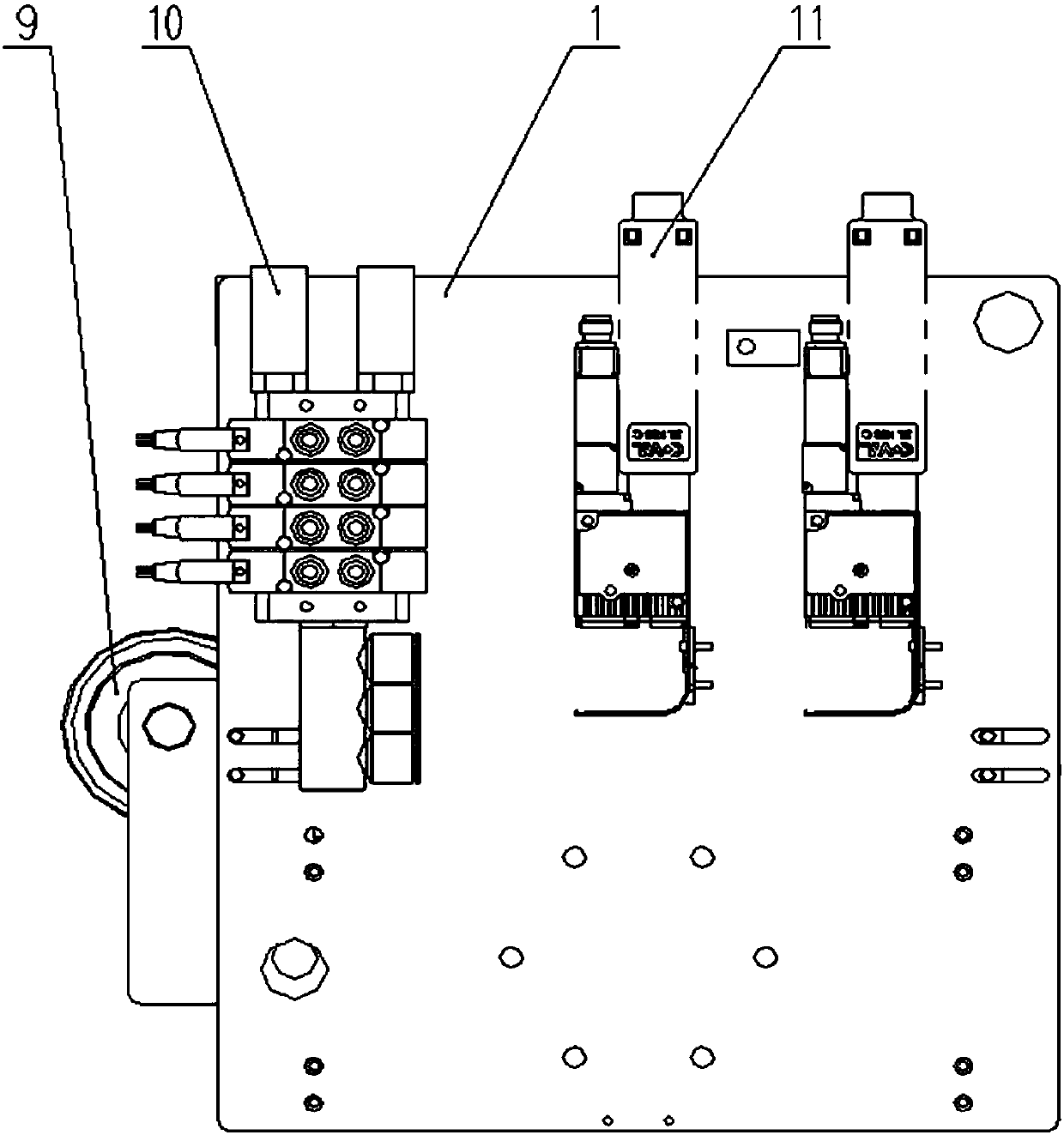

[0025] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a robot fixture, the present invention is characterized in that: it comprises upper installation board 1, lower installation board 4, the connection block 3 that is connected between upper and lower installation boards, the wrapping paper sucker 7 that is arranged in the bottom middle of lower installation board 4, is arranged on the lower The separation cardboard suction cup 9 on one side of the bottom of the mounting plate 4; the laser range finder 2 is arranged between the upper and lower mounting plates, and the paper pressure cylinder 5 and the laser range finder 2 are arranged on both sides of the wrapping paper suction cup 7 at the bottom of the lower mounting plate 4 Translate through the translation cylinder 6; there is also a rotary paper cutting mechanism 8 at the bottom of the lower mounting plate 4, a paper cutter type paper cutting mechanism 12 is connected to the side of the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com