Oil filling system and method for transmission

A technology of transmission oil and transmission, which is applied in special distribution devices, packaging, distribution devices, etc. It can solve the problems of increased workload in production management, adverse effects of oil injection accuracy, and high requirements for measurement accuracy, so as to reduce equipment investment costs and save Precise effect of oil injection time and oil injection amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

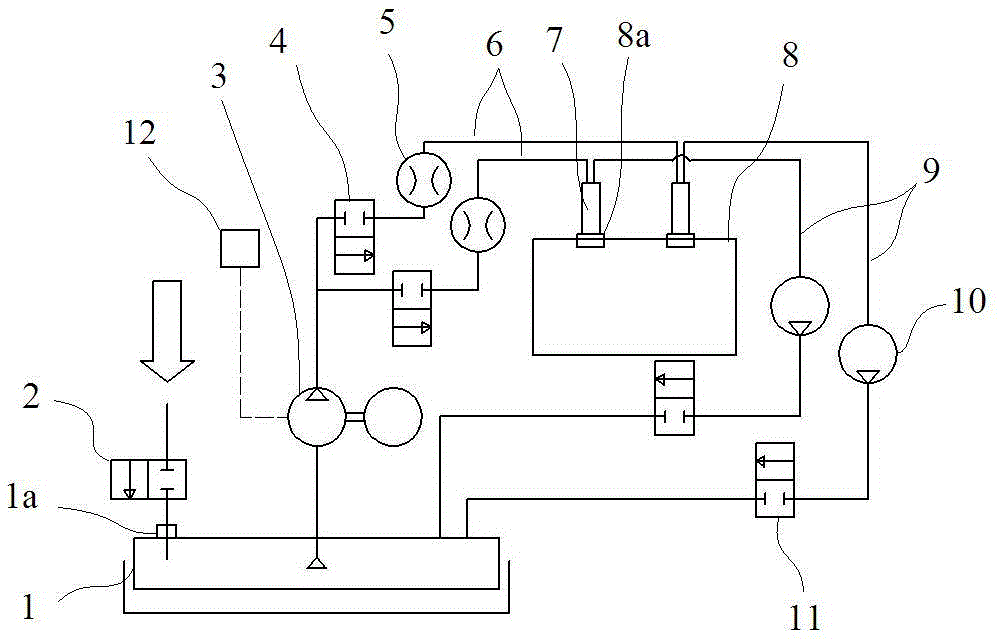

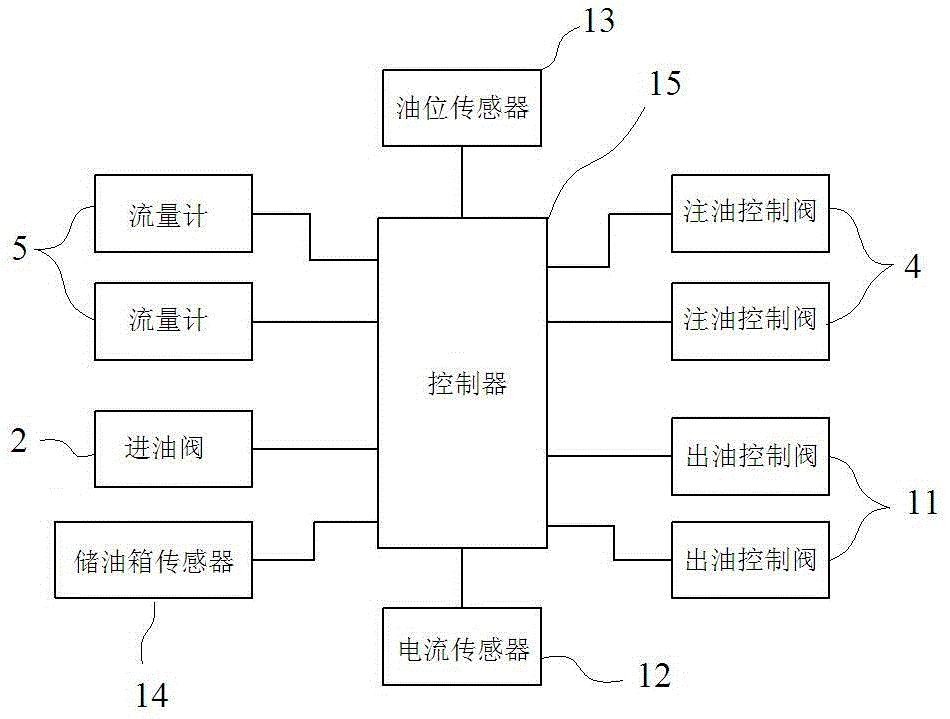

[0025] Such as figure 1 In the shown embodiment, a transmission oil filling system includes an oil storage tank 1, an oil injection main circuit, an oil injection branch circuit 6 and an oil outlet branch circuit 9, and a control part. Wherein, the oil storage tank is used for storing transmission oil, and the oil storage tank is provided with an oil inlet 1a, and an oil inlet valve 2 is arranged on the oil inlet. The oil inlet valve is a two-position two-way valve, which is used to control the connection between the oil inlet and the oil storage tank. The oil storage tank is equipped with an oil storage tank sensor 14 for measuring the liquid level in the oil storage tank. In addition, the oil storage tank is also equipped with a heating device and a dirty oil filtering device to keep the oil temperature of the transmission oil in an appropri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com