Aerated grit chamber with integrated functions of grit removing, skimming and oil removing

An integrated technology of aeration and sand settling, applied in the field of aeration sand settling tanks, can solve the problems of unsatisfactory slag and sand removal effect, difficulty in meeting water output requirements, large floor space, etc. The effect of good water quality, reduced land occupation and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

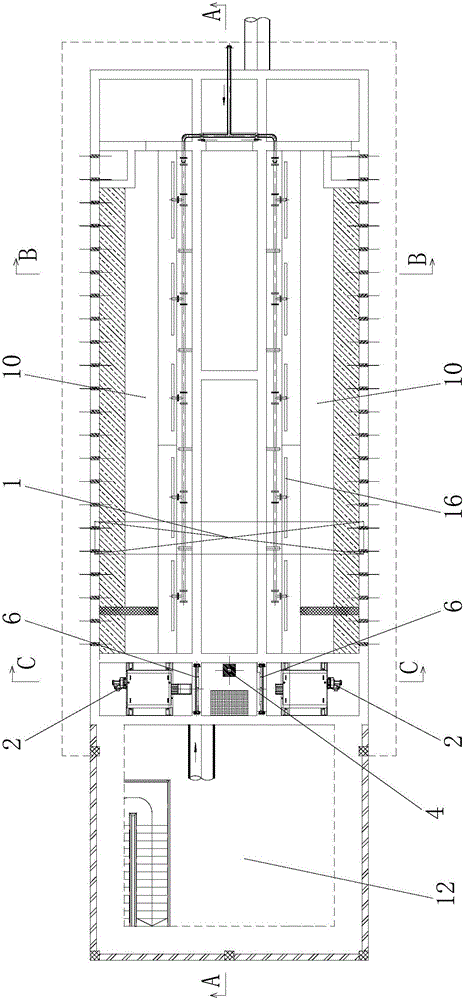

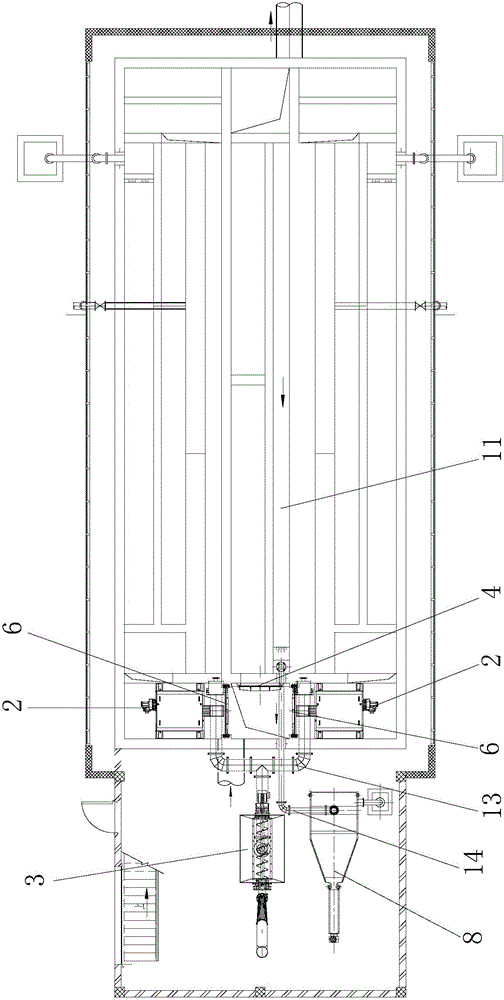

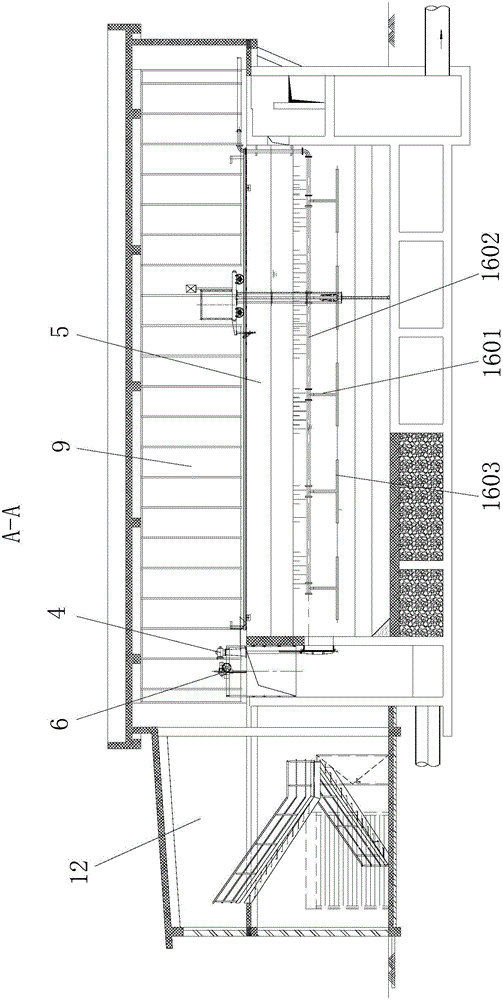

[0018] refer to Figure 1-6 , the specific implementation method adopts the following technical solutions: an aerated grit chamber integrating sand removal, scum removal and oil removal, including a double bridge sand suction machine 1, a fine grid decontamination machine 2, a screw press conveyor 3, a flashlight Dual-purpose lifting rod round gate 4, aeration grit chamber 5, electric channel gate 6, skimming device 7 and sand-water separator 8, aeration grit chamber 5 is set under the superstructure 9 of the grit chamber, aeration A grit chamber 10 and a sand discharge tank 11 are arranged in the grit chamber 5, a sand storage chamber 12 is arranged on one side of the aerated grit chamber 5, and a double bridge type sand suction machine 1 is installed above the aerated grit chamber 5 , a skimming device 7 is installed under the double-bridge sand suction machine 1, and a fine grid decontamination machine 2, a screw press conveyor 3, and a dual-purpose lifting rod circular gat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com