An energy-saving and environment-friendly formaldehyde production system and formaldehyde production method

A production system, formaldehyde technology, applied in the field of energy-saving and environment-friendly formaldehyde production system, can solve problems such as damage, easy fouling of methanol evaporator, etc., and achieve the effects of reducing power loss, significant energy saving effect, and small friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

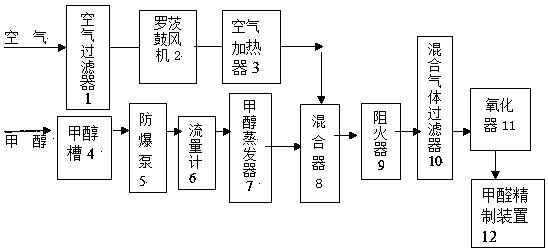

[0031] In order to clearly illustrate the technical characteristics of the present invention, the present invention is set forth below through specific embodiments, and the specific scheme of the present embodiment is as follows:

[0032] An energy-saving and environment-friendly production system for formaldehyde, comprising a parallel air treatment unit and a methanol treatment unit, the air treatment unit and the methanol treatment unit are connected to an oxidation unit, and a formaldehyde refining unit 12 connected in series with the oxidation unit, wherein the air The processing device is composed of an air filter 1, a Roots blower 2, and an air heater 3 connected in sequence. The air heater 3 is a combined heating device. The methanol processing device is composed of a methanol tank 4, an explosion-proof pump 5, and a flow meter 6 connected in sequence. , Methanol evaporator 7, wherein the methanol evaporator 7 is a plate evaporator.

[0033] In this embodiment, the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com