Sulfydryl and carboxyl functional pentaerythritol core starlike hyperbranched polymer, preparation method and application thereof

A technology of hyperbranched polymer and carboxyl functionalization, applied in the preparation of organic compounds, thiol preparation, carboxylate preparation and other directions, can solve the problems of poor acid resistance, increased leaching of heavy metals, large dosage of drugs, etc. Good anti-acid shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of mercapto and carboxyl functionalized pentaerythritol core star hyperbranched polymer

[0038] Add 13.60g (50%, 0.05mol) of the acetic acid solution of pentaerythritol into a four-neck flask with stirring, reflux condenser and thermometer, then add 39.20g (50%, 0.20mol) of the acetic acid solution of maleic anhydride, and stir evenly Afterwards, under nitrogen protection, the temperature was raised to 85° C., and the reaction was carried out for 4 hours to obtain pentaerythritol tetramaleate. Then cool down to 30°C, add 31.92g (50%, 0.21mol) methanol solution of thiourea while stirring, and react at 30°C for 18 hours, then distill under reduced pressure at 90°C to obtain a white solid, which is washed twice with water , filtered and dried in vacuo to obtain 40.78g of white solid, namely amidinosulfanyl and carboxyl functionalized pentaerythritol core star hyperbranched polymer, yield 98.03%. Put the obtained white solid into 100g aqueous sol...

Embodiment 2

[0041] Embodiment 2: Preparation of mercapto and carboxyl functionalized pentaerythritol core star hyperbranched polymer

[0042] Add 13.60g (50%, 0.05mol) of the acetic acid solution of pentaerythritol into a four-neck flask equipped with stirring, reflux condenser and thermometer, then add 39.79g (50%, 0.203mol) of the acetic acid solution of maleic anhydride, and stir evenly Afterwards, under nitrogen protection, the temperature was raised to 90° C., and the reaction was carried out for 3 hours to obtain pentaerythritol tetramaleate. Then cool down to 30°C, add 33.44g (50%, 0.22mol) methanol solution of thiourea while stirring, and react at 40°C for 16 hours, and distill under reduced pressure at 95°C to obtain a white solid, which is washed twice with water , filtered and dried in vacuo to obtain 41.19 g of white solid, namely amidinosulfanyl and carboxyl functionalized pentaerythritol core star hyperbranched polymer, yield 98.01%. Put the obtained white solid into 100g a...

Embodiment 3

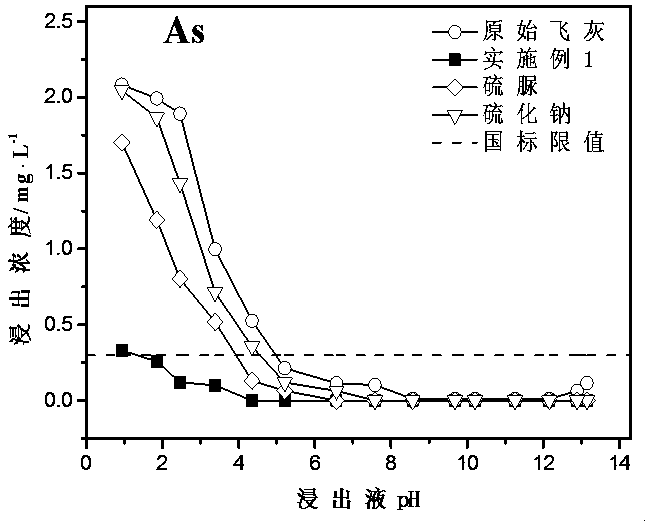

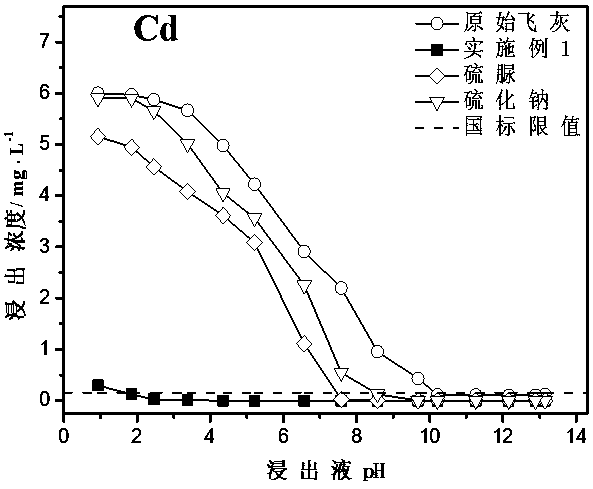

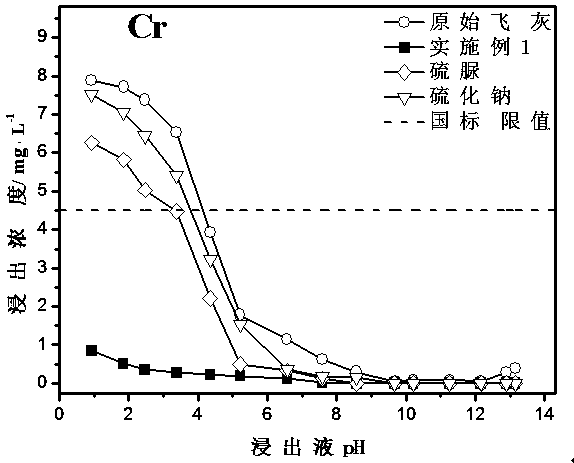

[0043] Example 3: Stabilization treatment of incineration fly ash

[0044] The incineration fly ash comes from a waste incineration plant. The leaching toxicity test adopts the acetic acid leaching toxicity test specified in the industry standard "Solid Waste Leaching Toxicity Leaching Method Acetic Acid Buffer Solution Method (HJ / T300-2007)", and the pollutant control standard is "Standards for Pollution Control of Domestic Garbage Landfill Sites (GB16889-2008)", the test results are shown in Table 1. It can be seen that the leaching concentration of Cd and Pb in the fly ash exceeds the national standard for the identification of hazardous waste leaching toxicity, and other heavy metal elements do not exceed the standard. Therefore, it must be stabilized to make the concentration of heavy metals in the leach solution lower than the standard limit before it can be landfilled.

[0045] The mercapto and carboxyl functionalized pentaerythritol core star-shaped hyperbranched poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com