A kind of toughened-flame-retardant epoxy resin material and preparation method thereof

An epoxy resin, flame retardant technology, applied in the field of composite materials and their preparation, can solve the problem that a single performance cannot meet the requirements of the comprehensive performance of the material, and achieves non-toxic by-products, high environmental and human safety, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Put 50 mesh natural scaly expandable graphite into a muffle furnace, expand it at a high temperature of 800°C for 5 seconds, add it to an acetone solvent, and ultrasonically disperse at 30 kHz for 12 hours to obtain expanded graphite.

[0044] Weigh 50 parts by weight of the compound of ammonium polyphosphate and melamine, wherein the weight ratio of ammonium polyphosphate and melamine is 10:1, 10 parts by weight of bisphenol A benzoxazine (structure a), add 40 Parts by weight of acetone and 80 parts by weight of polyethylene glycol were stirred for 20 minutes at 300 rpm at room temperature in a stirrer, and then dispersed for 20 minutes using 20 kHz ultrasound to obtain a uniformly mixed suspension. The system was heated to 40°C, mechanically stirred at 300 rpm, and acetone was removed by suction filtration under reduced pressure. Continue to heat up the mixed system to 120°C, mechanically stir and react for 3h, then heat up to 160°C for 4h. After being naturally cooled ...

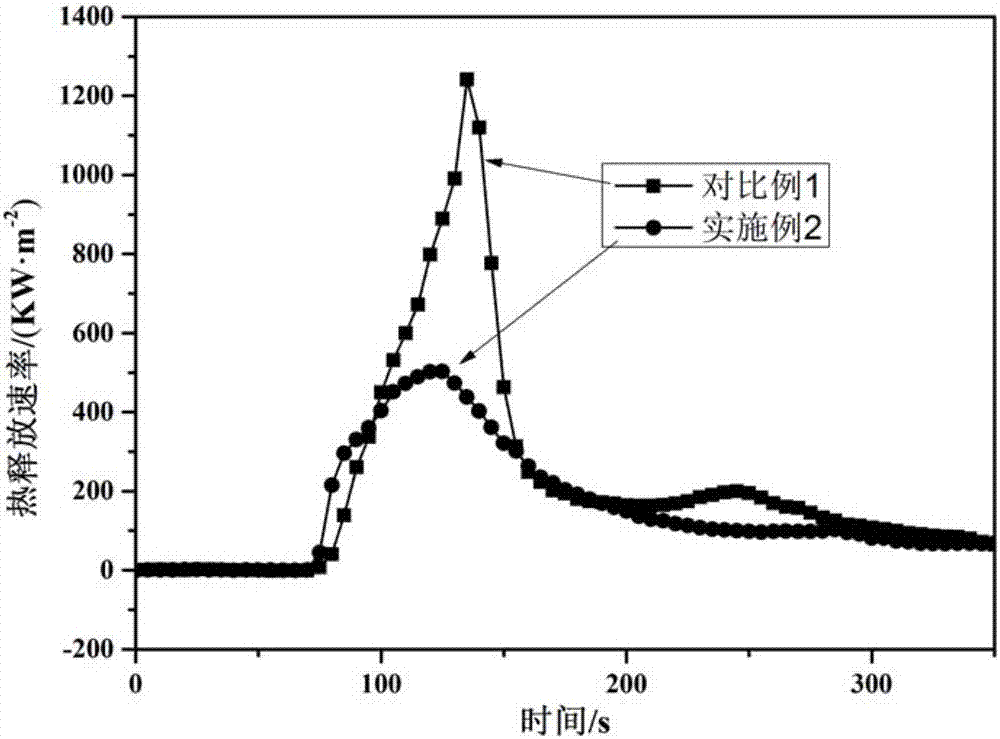

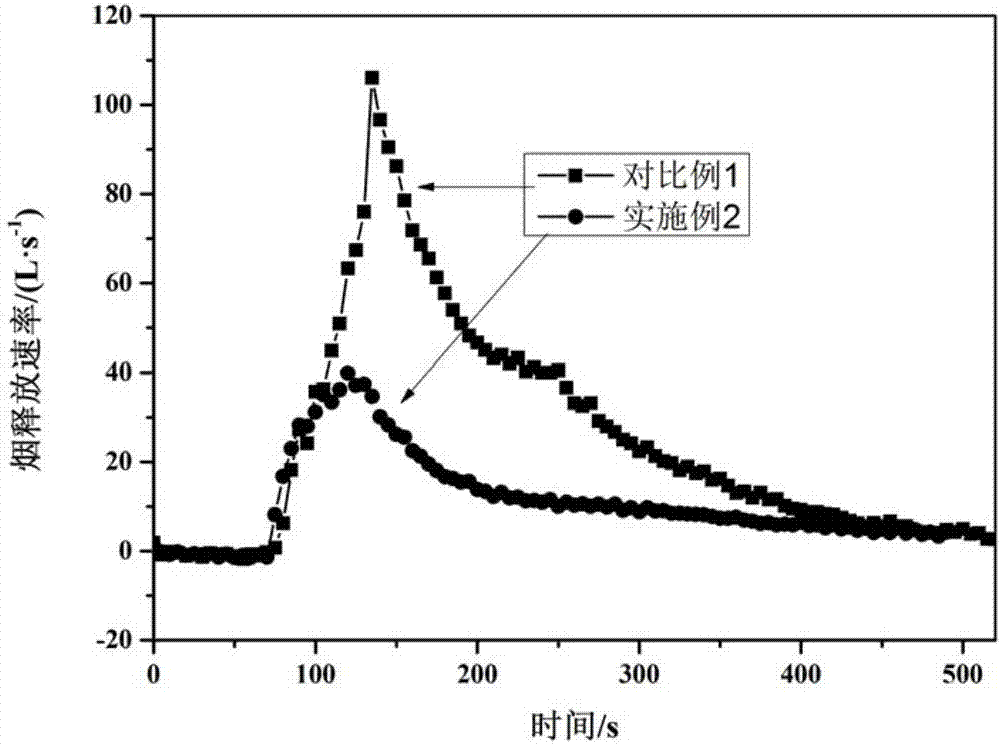

Embodiment 2

[0047] Put 100 mesh natural scaly expandable graphite into a muffle furnace, expand it at a high temperature of 1000°C for 15 seconds, add it to an acetone solvent, and ultrasonically disperse at 50 kHz for 8 hours to obtain expanded graphite.

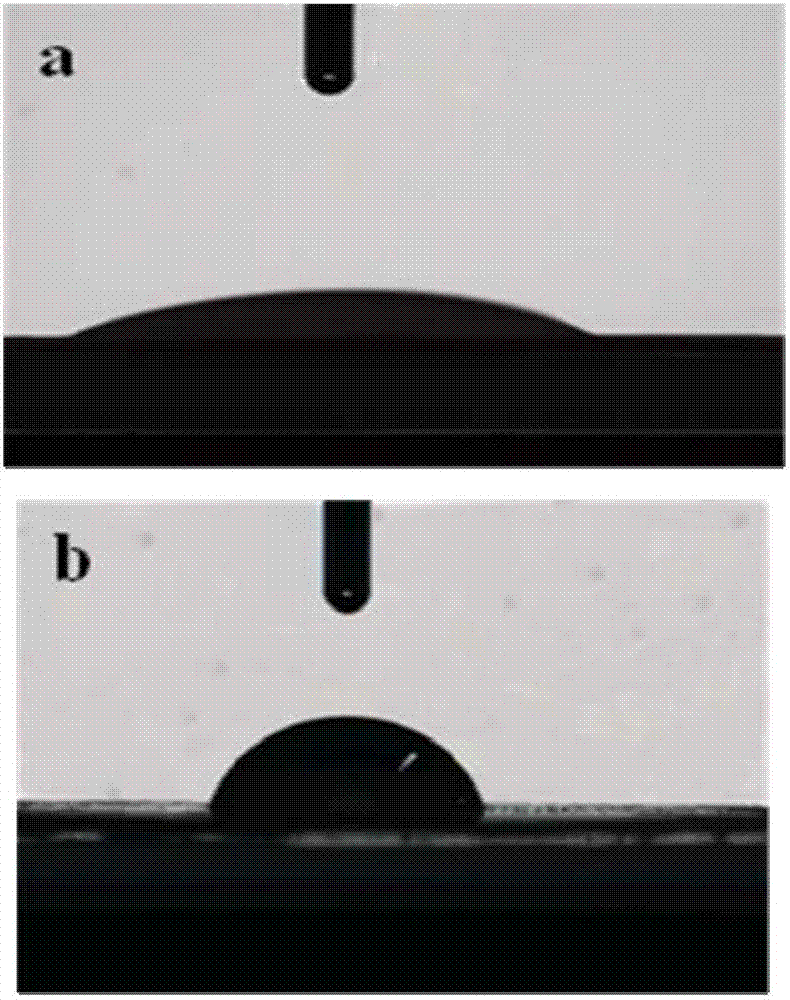

[0048] Weigh 90 parts by weight of ammonium polyphosphate and 10 parts by weight of allyl benzoxazine (structure b), add 50 parts by weight of dichloromethane and 90 parts by weight of polydimethylsiloxane, and stir After stirring for 30 minutes at 400 rpm at room temperature in the vessel, 50 kHz ultrasound was used for dispersion for 20 minutes to obtain a uniformly mixed suspension. The system was heated to 70°C, mechanically stirred at 400 rpm, and dichloromethane was removed by suction filtration under reduced pressure. Continue to heat up the mixed system to 150°C, mechanically stir and react for 4h, then heat up to 180°C for 1h. After being naturally cooled to room temperature, stirring is stopped, and after repeated washing with ...

Embodiment 3

[0053] Putting 300 mesh natural scaly expandable graphite into a muffle furnace, expanding at a high temperature of 1000°C for 10 seconds, adding it to an acetone solvent, and dispersing ultrasonically at 80 kHz for 6 hours to obtain expanded graphite.

[0054] Weigh 90 parts by weight of the compound of ammonium polyphosphate and melamine, wherein the weight ratio of ammonium polyphosphate and melamine is 10:3, 30 parts by weight of cardanol type benzoxazine (structure d), add 60 parts by weight Parts of ethyl acetate and 95 parts by weight of phenyl methyl silicone oil were stirred in a mixer at room temperature at 600 rpm for 40 minutes, and then dispersed with 80 kHz ultrasound for 60 minutes to obtain a uniformly mixed suspension. The system was heated to 65°C, mechanically stirred at 600 rpm, and ethyl acetate was removed by suction filtration under reduced pressure. Continue to heat up the mixed system to 120°C, mechanically stir and react for 5h, then heat up to 200°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com