Surface powder spraying flame-retardant technology for fibrilia composite material

A composite material and hemp fiber technology, which is applied in the field of flame-retardant composite material preparation, can solve the problems of reducing the mechanical properties of composite materials, reducing the toughness of hemp fiber, weakening the compatibility between hemp fiber and the matrix, and achieving excellent flame-retardant performance and The effect of simple mechanical properties and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

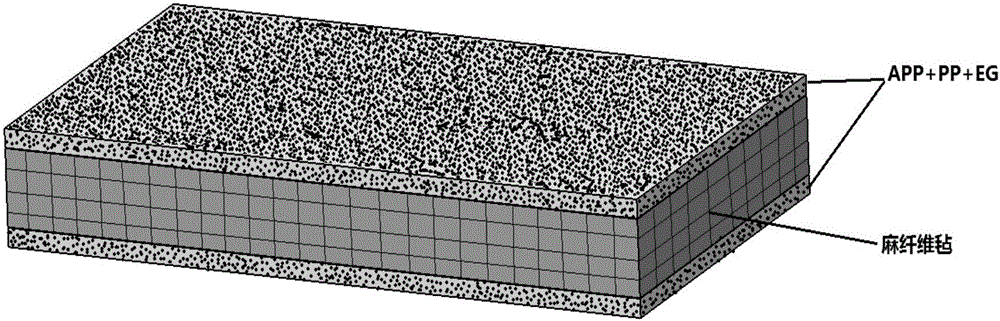

Image

Examples

Embodiment 1

[0018] A. Surface dusting

[0019] Cut the hemp fiber composite mat with a mass of 38g and a size of 170*170mm, then weigh 2.375g of EG powder and 9.5g of PP powder, and spray the PP powder evenly on the upper and lower surfaces of the composite fiber mat, and then spray the EG evenly on the composite material The upper and lower surfaces of the fiber mat.

[0020] B. Thermoforming

[0021] The composite hemp fiber felt prepared in the above steps is preheated in a hot pressing mold, and then hot pressed once to obtain a hemp fiber composite material board with excellent flame retardancy and mechanical properties.

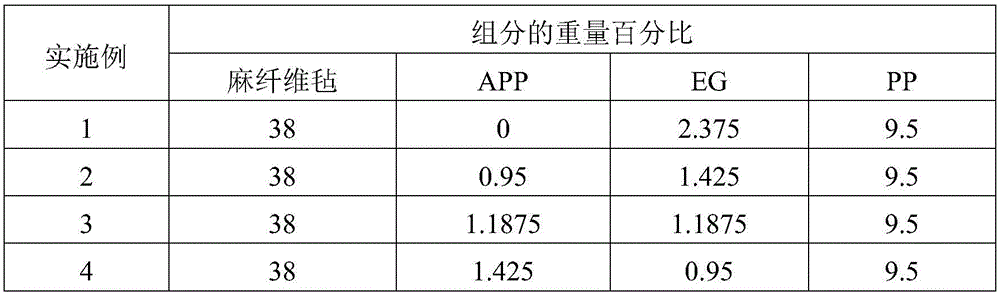

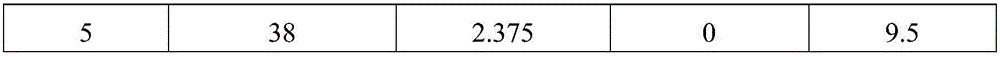

[0022] The content and performance of each component of the hemp fiber composite board are shown in Table 1 and Table 2, respectively.

Embodiment 2

[0024] A. Surface dusting

[0025] Cut out hemp fiber composite mats with a mass of 38g and a size of 170*170mm, then weigh 1.425g of EG powder, 0.95g of APP powder and 9.5g of PP powder, mix the APP and PP powder evenly, and spray them on the upper and lower surfaces of the composite fiber mat. Then spray EG evenly on the upper and lower surfaces of the composite fiber mat.

[0026] B. Thermoforming

[0027] The composite hemp fiber felt prepared in the above steps is preheated in a hot pressing mold, and then hot pressed once to obtain a hemp fiber composite material board with excellent flame retardancy and mechanical properties.

[0028] The content and performance of each component of the hemp fiber composite board are shown in Table 1 and Table 2, respectively.

Embodiment 3

[0030] A. Surface dusting

[0031] Cut the hemp fiber composite material mat with a mass of 38g and a size of 170*170mm, then weigh 1.1875g of EG powder, 1.1875g of APP powder and 9.5g of PP powder, mix the APP and PP powder evenly, and spray them on the upper and lower surfaces of the composite fiber mat. Then spray EG evenly on the upper and lower surfaces of the composite fiber mat.

[0032] B. Thermoforming

[0033] The composite hemp fiber felt prepared in the above steps is preheated in a hot pressing mold, and then hot pressed once to obtain a hemp fiber composite material board with excellent flame retardancy and mechanical properties.

[0034] The content and performance of each component of the hemp fiber composite board are shown in Table 1 and Table 2, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com