High-elasticity halogen-free flame-retardant thermoplastic elastomer and preparation method thereof

A technology of thermoplastic elastomer and high elasticity, which is applied in the field of polymer materials, can solve the problems of large amount of flame retardant added, reduced mechanical properties of materials, poor compatibility, etc., and achieves good processing formability, good compatibility, good The effect of flame retardancy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

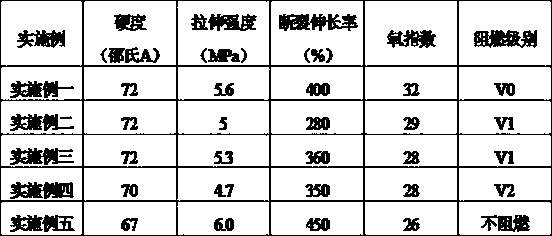

Examples

preparation example Construction

[0020] Its preparation method comprises the following steps:

[0021] S1. Weigh the thermoplastic elastomer TPV, melamine phosphate, resorcinol bis(diphenyl phosphate), expandable graphite and polysiloxane by weight;

[0022] S2. First put the melamine phosphate and resorcinol bis(diphenyl phosphate) weighed in step S1 in a high-speed mixer, mix at a speed of 600r / min for 3min, and then add expandable graphite and polysilicon For boroxane, keep the speed constant, mix for 5 minutes, and finally add thermoplastic elastomer TPV, keep the speed constant, mix for 6 minutes, until all materials are mixed evenly;

[0023] S3. Discharge the homogeneously mixed raw materials in step S2 from the high-speed mixer, pour them into the feeder, and feed them into the twin-screw extruder for extrusion. The main engine speed of the twin-screw extruder is 600r / min, the temperature of the twin-screw extruder is 190°C;

[0024] S4. Stranding the material extruded in step S3, cooling to room t...

Embodiment 2

[0026] A highly elastic halogen-free flame-retardant thermoplastic elastomer proposed by the present invention includes the following raw materials in weight percentage: thermoplastic elastomer TPV 75%, melamine phosphate 10%, resorcinol bis(diphenyl phosphate) 8% , Expandable graphite 5%, polysiloxane 2%.

[0027] Its preparation method comprises the following steps:

[0028] S1. Weigh the thermoplastic elastomer TPV, melamine phosphate, resorcinol bis(diphenyl phosphate), expandable graphite and polysiloxane by weight;

[0029] S2. First put the melamine phosphate and resorcinol bis(diphenyl phosphate) weighed in step S1 in a high-speed mixer, mix at a speed of 300r / min for 5min, and then add expandable graphite and polysilicon For boroxane, keep the speed constant, mix for 3 minutes, and finally add thermoplastic elastomer TPV, keep the speed constant, mix for 8 minutes, until all materials are mixed evenly;

[0030] S3. Discharge the homogeneously mixed raw materials in ...

Embodiment 3

[0033] A highly elastic halogen-free flame-retardant thermoplastic elastomer proposed by the present invention includes the following raw materials in weight percentage: thermoplastic elastomer TPV 75%, melamine phosphate 15%, resorcinol bis(diphenyl phosphate) 5% , Expandable graphite 4%, polysiloxane 1%.

[0034] Its preparation method comprises the following steps:

[0035] S1. Weigh the thermoplastic elastomer TPV, melamine phosphate, resorcinol bis(diphenyl phosphate), expandable graphite and polysiloxane by weight;

[0036] S2. First put the melamine phosphate and resorcinol bis(diphenyl phosphate) weighed in step S1 in a high-speed mixer, mix at a speed of 500r / min for 2min, and then add expandable graphite and polysilicon For boroxane, keep the speed constant, mix for 4 minutes, and finally add thermoplastic elastomer TPV, keep the speed constant, mix for 7 minutes, until all materials are mixed evenly;

[0037] S3. Discharge the homogeneously mixed raw materials in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com