Carbonization method implemented through gas cyclic heating

A technology of gas circulation and gas heating, applied in chemical instruments and methods, gasification processes, carbon compounds, etc., can solve problems such as difficult reuse, high heat loss, and low thermal efficiency, and achieve water resource consumption savings and heat loss The effect of reducing and improving the energy efficiency of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

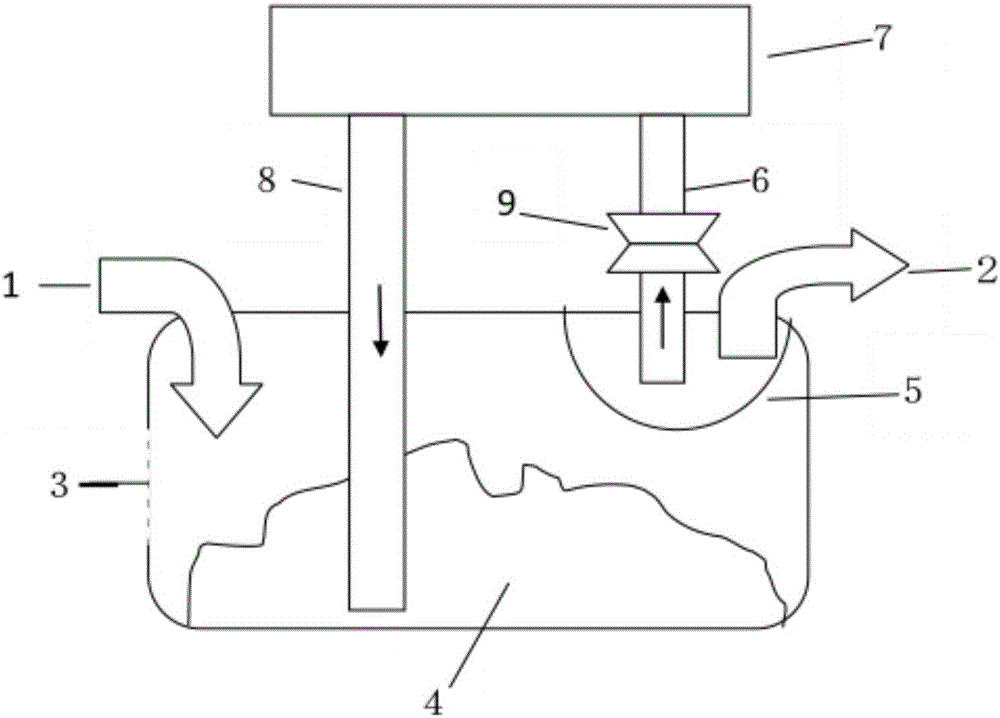

[0037] In this embodiment, the structure of a carbonization method using gas circulation heating is as follows figure 1 Shown. A carbonization method using gas circulation heating, including a carbonization device 3, a superheated steam inlet 1, a superheated steam outlet 2, and an air suction pipe 6 and a jet pipe 8, the suction pipe 6 is connected to carbonization at one end The other end of the cavity of the device 3 is connected to the inlet of the heating device 7; one end of the jet pipe 8 is connected to the outlet of the heating device 7, and the other end is connected to the material of the carbonization device 3; the suction pipe 6, the heating device 7. The jet pipe 8 forms a gas circulation heating loop.

[0038] In this embodiment, a carbonization method using gas circulation heating is used for carbonization. The implementation process of carbonization is as follows: superheated steam enters the carbonization equipment 3 from the superheated steam inlet 1 to release...

Embodiment 2

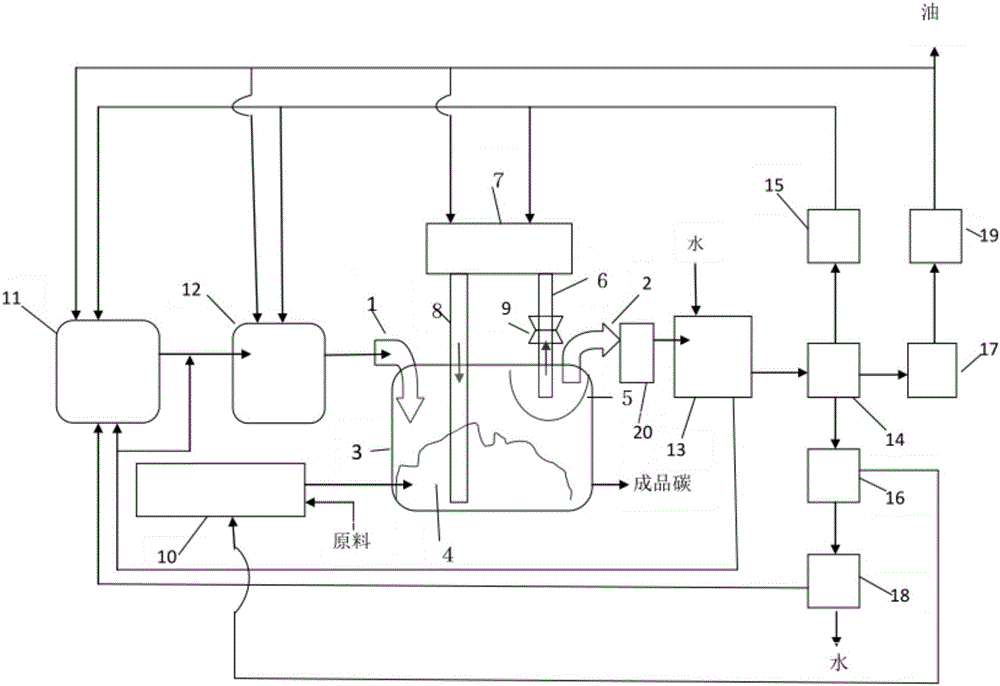

[0042] The structure reference of a carbonization method using gas circulation heating in this embodiment figure 2 , A carbonization method using gas circulation heating, comprising a carbonization device 3, a superheated steam inlet 1, a superheated steam outlet 2, and an air suction pipe 6 and a jet pipe 8, the suction pipe 6 is connected at one end The other end of the cavity of the carbonization device 3 is connected to the inlet of the heating device 7; one end of the jet pipe 8 is connected to the outlet of the heating device 7, and the other end is connected to the material of the carbonization device 3; the suction pipe 6, heating Equipment 7, jet pipe 8 constitutes a gas circulation heating loop. A dust collector 5 is installed at the steam outlet 2. The superheated steam inlet 1 is connected to the superheated steam generator 12 and the steam boiler 11.

[0043] The steam outlet 2 is connected to a separation device 14, which includes a gas-liquid separation device an...

Embodiment 3

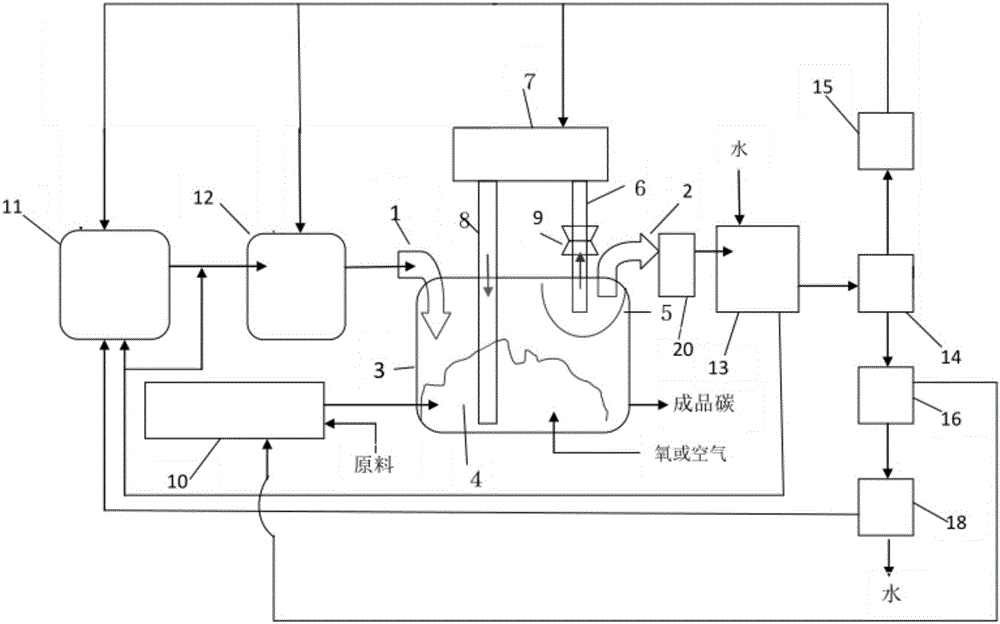

[0058] Structural reference of the scheme adopted in this embodiment image 3 The difference from Example 2 is that in the process described in Scheme 3, the output contains almost no oil, so the equipment does not require an oil-water separation device, an oil processing device, and an oil storage device.

[0059] The heating equipment first heats the gas to 150°C to 300°C, preheats the materials, and reacts for 0.1 to 24 hours (depending on the amount of materials and the direction of movement of the materials in the carbonization device, the reaction time varies). , The heating device heats the gas to 700°C to 1700°C to heat and carbonize the material, and cyclically react for 0.1 to 48 hours (depending on the amount of material and the direction of movement of the material in the carbonization device, the reaction time varies); or The heating equipment directly heats the gas to 700°C to 1700°C to heat and carbonize the material, and the cycle reacts for 0.1 to 72 hours (depen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap