Method for directional accumulation of specific homolog components of antimicrobial lipopeptides of bacilli

An antibacterial lipopeptide and bacillus technology, applied in the field of fermentation, can solve the problems of narrow antibacterial spectrum, single component, single function of lipopeptide products, etc., to achieve the effect of improving efficacy and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The BPY medium was used as the seed medium, and the seed solution was obtained by culturing for 18-24 hours. For liquid fermentation, the seed liquid was added to Landy medium at 5% (v / v), and the volume of the liquid was 80mL / 250mL in a Erlenmeyer flask. At 28°C, when the shaking table rotated at 160r / min, cultured for 48h, and the fermentation liquid was placed in Centrifuge at 10,000rpm for 15min, take the supernatant, adjust the pH to 2 with hydrochloric acid, let stand overnight, centrifuge at 10,000rpm for 20min, take the precipitate, dissolve it with methanol, adjust the pH to 7.0, centrifuge at 10,000rpm for 20min, take the supernatant and use rotary evaporation The instrument was concentrated at 60°C, and extracted with methanol three times. After concentration, the sample was placed in a refrigerator at 4°C for later use to obtain the fermentation extract.

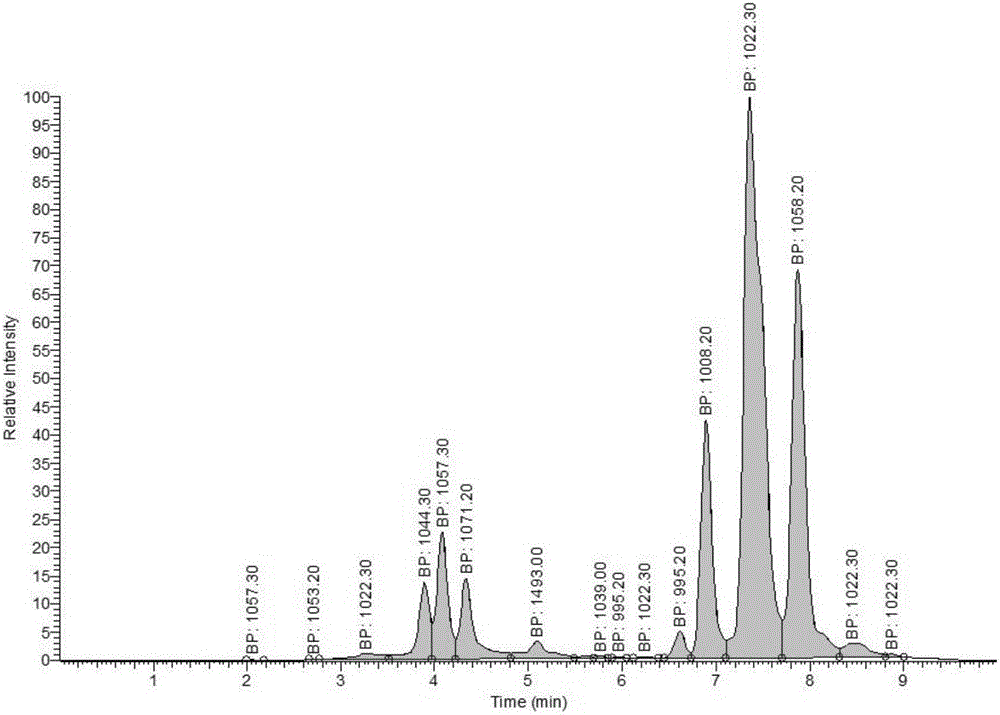

[0031] The yield of lipopeptide obtained after detection was 723.82mg·L -1, the produced Iturin compon...

Embodiment 2

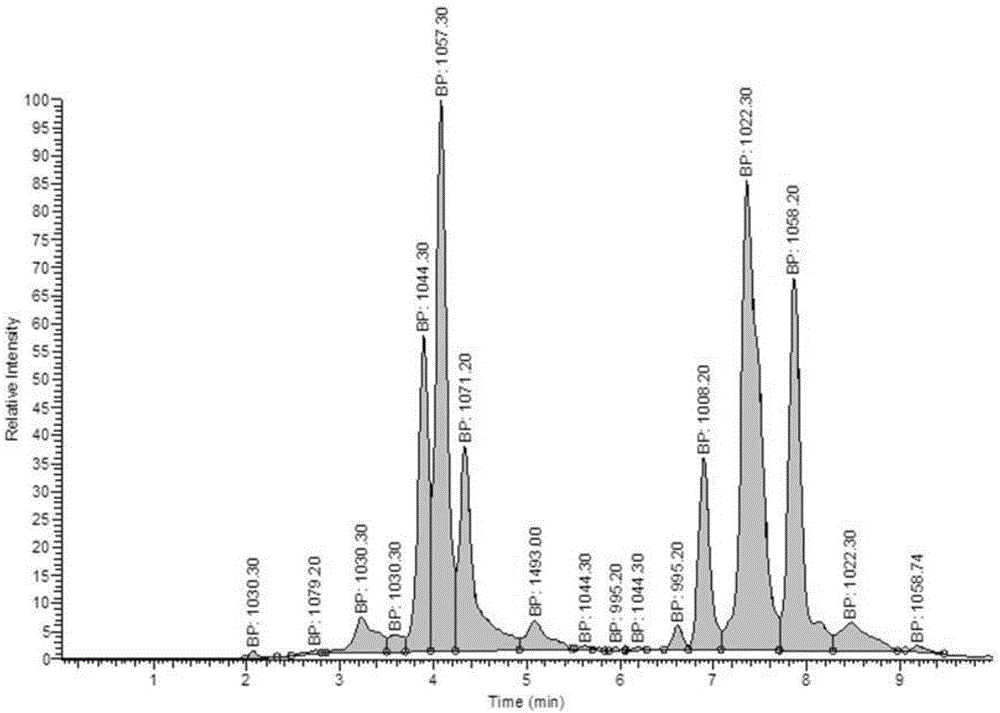

[0033] The inoculum size was the same as in Example 1, using Landy medium, at 30°C, at a shaker speed of 160r / min, cultured for 48h, and the output of lipopeptide was 763.20mg L -1 , the produced Iturin component accounts for 74.32% of the total mass, and Iturin is mainly composed of homologue components with mass-to-core ratios of 1044.30, 1057.20 and 1071.20, and the proportions of each homologue in the Iturin component are 2.40%, 3.67%, 93.93%. The content of Surfactin components accounted for 25.68%, mainly composed of homologues with mass-to-core ratios of 995.20, 1008.20, 1022.30 and 1058.20, and the proportions of each homologue in Surfactin components were 28.57%, 23.53%, 32.05% and 15.85% respectively .

Embodiment 3

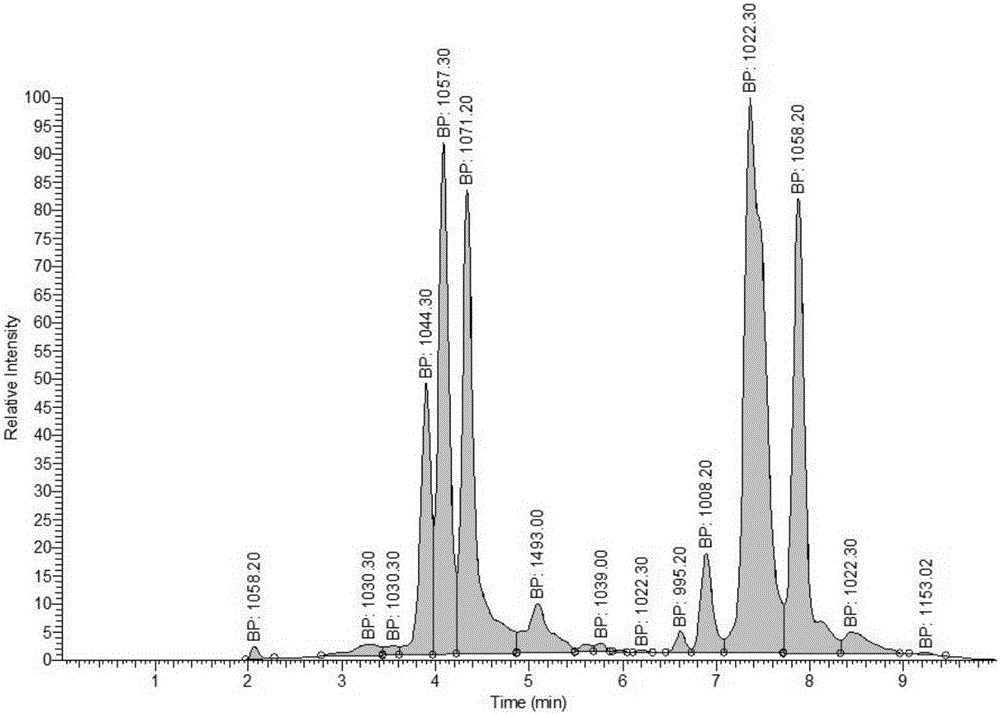

[0035] The amount of inoculum was the same as in Example 1, using Landy medium, at 32°C, at a shaker speed of 160r / min, cultured for 48h, and the output of lipopeptide was 872.01mg L -1 , the produced Iturin component accounted for 71.46% of the total mass, and Iturin was mainly composed of homologue components with mass-to-core ratios of 1044.30, 1057.20 and 1071.20, and the proportions of each homologue in the Iturin component were 4.92%, 9.59%, 85.49%. The content of Surfactin component accounts for 28.54%, mainly composed of homologues with mass-to-core ratios of 995.20, 1008.20, 1022.30 and 1058.20, and the proportions of each homologue in Surfactin components are 31.28%, 22.05%, 30.54% and 16.13% respectively .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com