Cooling device for water jet loom

A technology for water jet looms and cooling devices, which is applied in looms, textiles, textiles, and papermaking, etc. It can solve problems such as the decrease of electromagnetic pin attraction, the timing deviation of electromagnetic pin lifting, and poor weft insertion, so as to eliminate condensation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

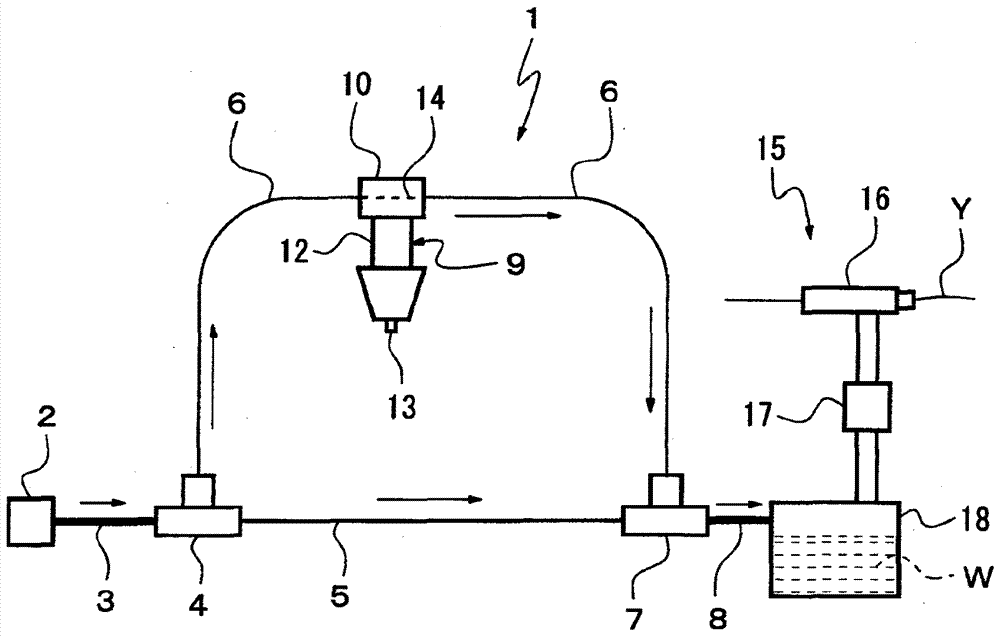

[0023] based on figure 1 and figure 2 The first embodiment will be described. figure 1 It is a block diagram showing the water supply path of the cooling device 1 in the water jet loom. In the cooling device 1 , a water supply source 2 such as a tap water pipe or a water storage tank is connected to a branch joint 4 via a water supply pipe 3 . The branch joint 4 branches the water supply element pipe 3 into a water supply main pipe 5 and a cooling water branch pipe 6 .

[0024] The water supply main pipe 5 is connected to a confluence pipe 8 by means of a manifold joint 7 . Therefore, a part of the weft insertion water W flowing through the water supply element pipe 3 is supplied to the junction pipe 8 through the water supply main pipe 5 and the collective joint 7 . The cooling water bifurcated pipe 6 connects the bifurcated joint 4 with one end of a water passage block (water passage block) 10 arranged on the weft yarn locking part 9 of the weft yarn length measuring st...

no. 2 Embodiment approach )

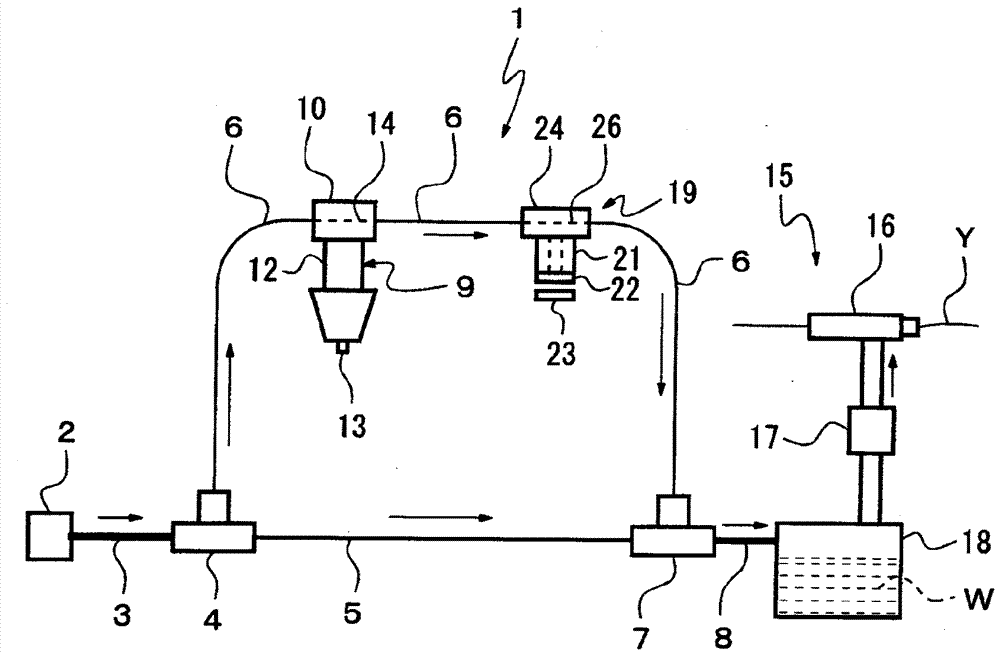

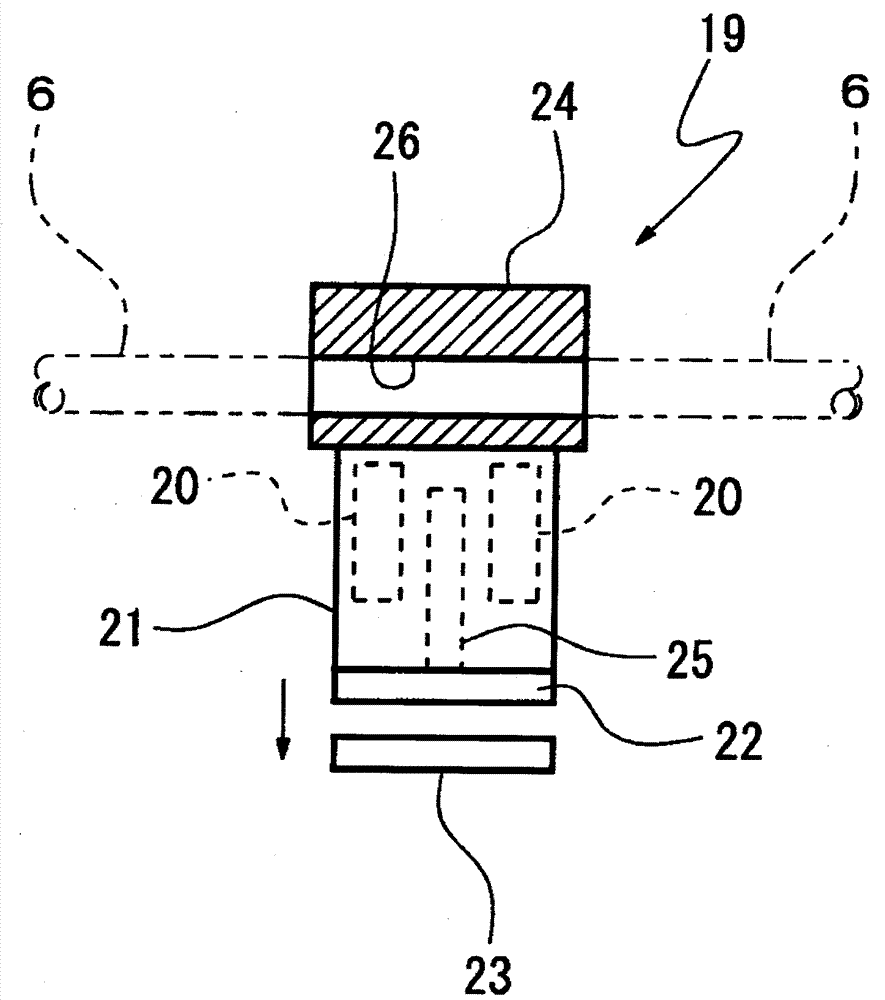

[0038] image 3 and Figure 4 The second embodiment is shown, and the same configurations as those of the first embodiment will be described with the same reference numerals, and detailed description will be omitted. The second embodiment is a structure capable of cooling the weft locking member 9 and the clamper 19 which are heat sources. The clamper 19 is arranged between the weft yarn length measuring storage device (not shown in the figure) and the weft insertion nozzle 16, and has the function of clamping the weft yarn Y after the weft insertion is completed.

[0039] Holder 19 as Figure 4 As shown in enlargement, it is composed of a main body 21, a movable clamper 22, and a fixed clamper 23. The main body 21 is equipped with a solenoid 20, and the movable clamper 22 is movably arranged at one end of the main body 21. On the side, the movable clamper 22 is flat, and the fixed clamper 23 is disposed opposite to the movable clamper 22, and the fixed clamper 23 is flat. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com