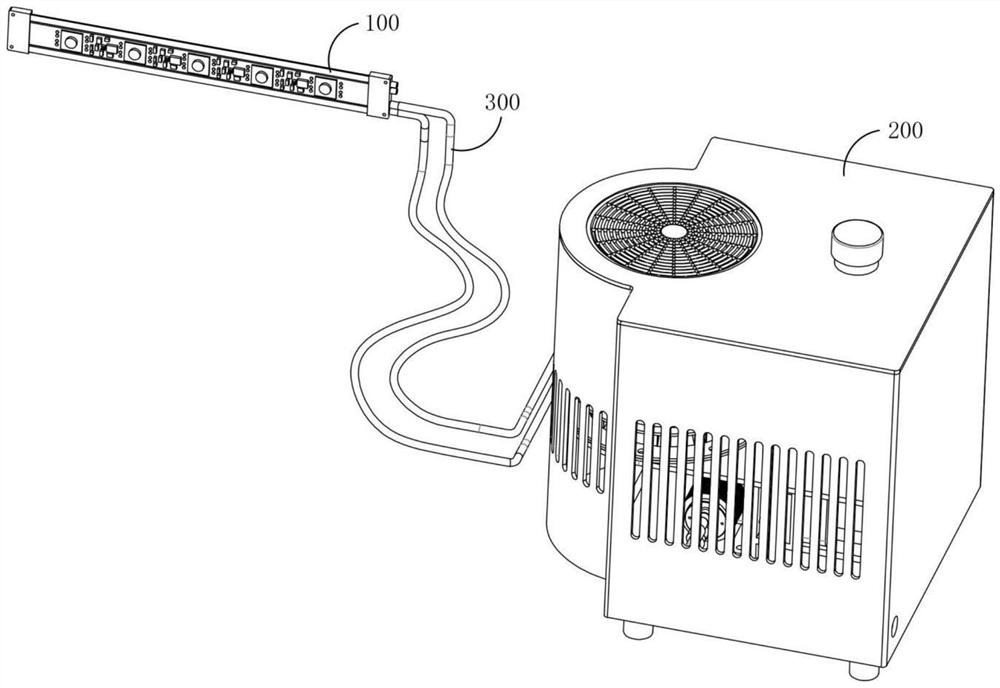

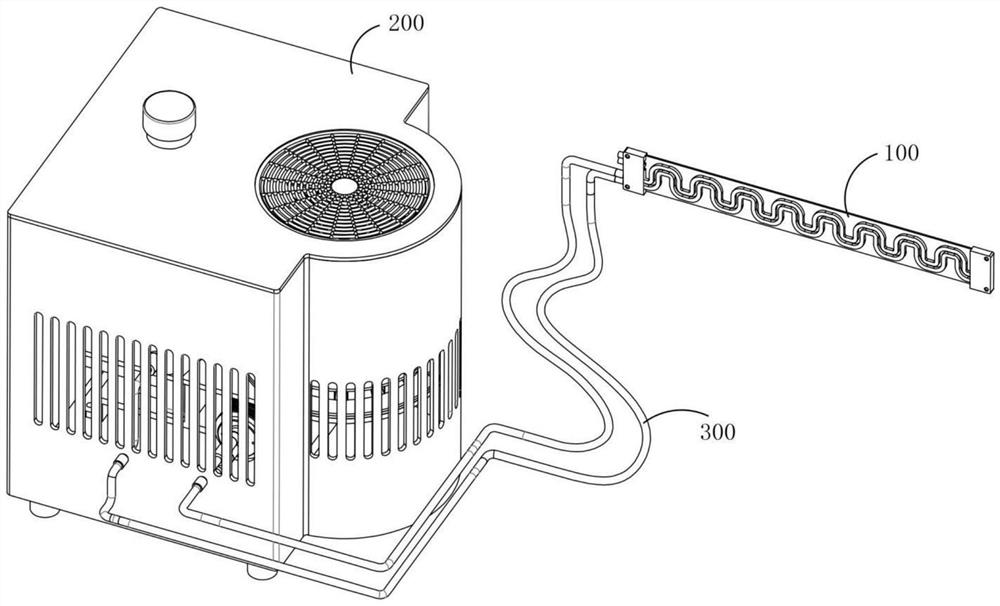

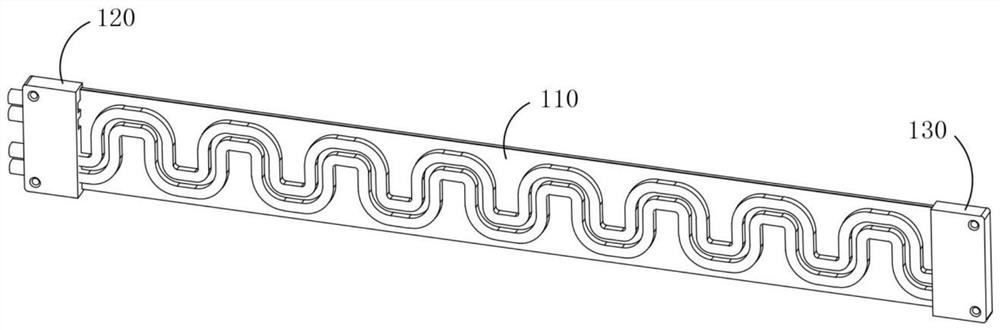

Circulating liquid cooling method for flexible circuit board

A flexible circuit board and circulating fluid technology, which is applied in the direction of modification using liquid cooling, modification of cooling/ventilation/heating, modification by conduction heat transfer, etc. problem, to achieve a good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to further illustrate the technical means and efficacy of the present invention to achieve predetermined amount of invention, the specific embodiments, structures, features, and efficacy of the present invention will be described in detail below with reference to the accommodation invention.

[0077] A flexible circuit board circulating liquid cooling method, its steps are:

[0078] S1: The reduction motor 510 in the inlet and outlet mechanism 500 operates with the link member 520, so that the plunger pump A530 in the inlet and outlet mechanism 500 is in the suction state, and the plunger pump B540 is in the discharge state, wherein the column of the suction state The plug pump A530 causes the coolant in the reservoir 400 through the connecting pipe A301 in the connecting pipe network 300 into the cooling pipe B113 in the cooling member 100 and the cooling tube A112, while the pumping state The plug pump A530 also enables the coolant 553 that is previously located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com