Simulation experiment device and experiment method of non-hydrocarbon gas and steam wellbore state

A technology for simulating experimental devices and experimental methods, which is applied in the field of simulating experimental devices for non-hydrocarbon gas and steam wellbore states, can solve the problem that the three-phase ratio cannot be mastered, the steam dryness measuring device cannot accurately simulate and control the wellbore dryness, and the difficulty in Simulate problems such as downhole dynamic environment to achieve the effect of controllable injection and displacement and measurable dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

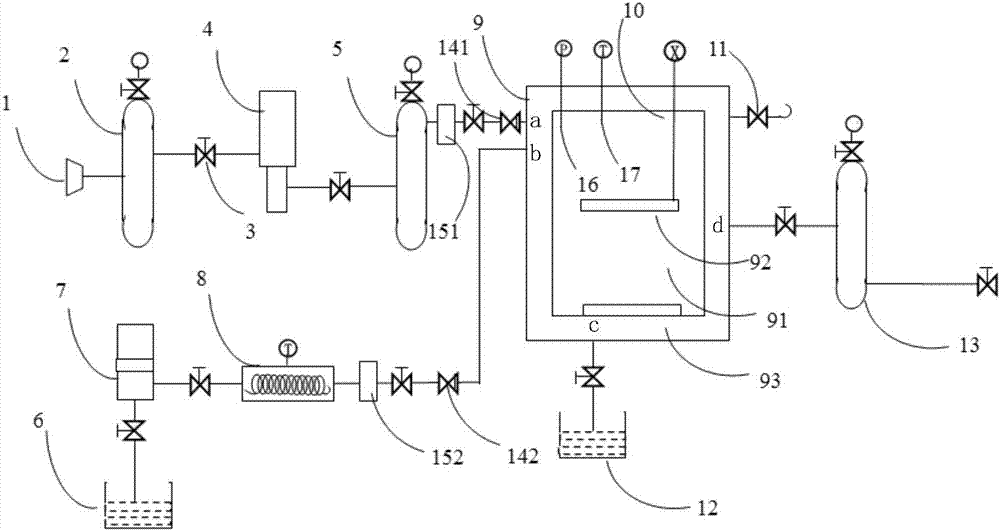

[0079] Such as figure 1 As shown, the present invention provides a kind of simulation experiment device of non-hydrocarbon gas and steam wellbore state, and described simulation experiment device comprises:

[0080] A sealed kettle 9, which has a chamber 91 for simulating a wellbore, and the sealed kettle 9 is provided with a first injection port a, a second injection port b, a first injection port communicated with the chamber 91 The outlet c and the second outlet d; the sealed kettle 9 is provided with a heating device for heating the chamber 91; the chamber 91 is provided with a temperature probe 17 and a pressure probe 16;

[0081] A non-hydrocarbon gas injection system, the non-hydrocarbon gas injection system is connected to the first injection port a through a pipeline, and is used to inject non-hydrocarbon gas into the chamber 91;

[0082] a steam injection system, the steam injection system is connected to the second injection port b through a pipeline, and is used t...

Embodiment 2

[0095] In order to accurately adjust the gas / steam mixing in the sealed kettle 9 and accurately simulate the temperature and pressure state parameters at any depth in the well, the present invention also provides an experimental method using the simulation experimental device, and the experimental method includes the following steps :

[0096] S11. Start the non-hydrocarbon gas injection system and the steam injection system, inject non-hydrocarbon gas and steam into the chamber 91; control the injection amount of the non-hydrocarbon gas and steam so that the chamber 91 Reach the set pressure, and make the inside of the chamber 91 reach the set temperature through the heating device;

[0097] S22, measuring the amount of liquid water discharged from the sealed kettle 9 through the drainage receiver;

[0098] S33, measuring the amount of steam and the amount of non-hydrocarbon gas in the mixed gas discharged from the sealed tank 9 through the exhaust receiver;

[0099] S44. C...

Embodiment 3

[0103] In order to check the accuracy of the wellbore dryness tester 10, the present invention also provides an experimental method. On the basis of the experimental method in the second embodiment, the experimental method in the present embodiment also includes the following steps:

[0104] S10. Before step S11, place the dryness tester 10 to be checked on the holding platform 92 in the sealed kettle 9; and connect the dryness tester 10 with an external data display device for reading .

[0105] S34, after step S33, the total amount of remaining liquid water and steam in the sealed kettle 9 is calculated as: W S =W 1 -W 2 -W 3 ,in

[0106] W S For the total amount of remaining liquid water and steam in the sealed kettle 9, the unit is mole (the molar weight can be determined by the ratio of the mass of the substance to the molar mass, the same below);

[0107] W 1 Be the amount of steam injected into the sealed kettle 9, in moles;

[0108] W 2 is the amount of discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com