Maintenance-free hub assembly

A maintenance-free, hub technology, applied in the direction of hubs, casters, wheels, etc., can solve the problems of regular maintenance of wheel bearings, hidden dangers of vehicle safety, etc., and achieve the effect of improving cooling effect, improving service life and smooth circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

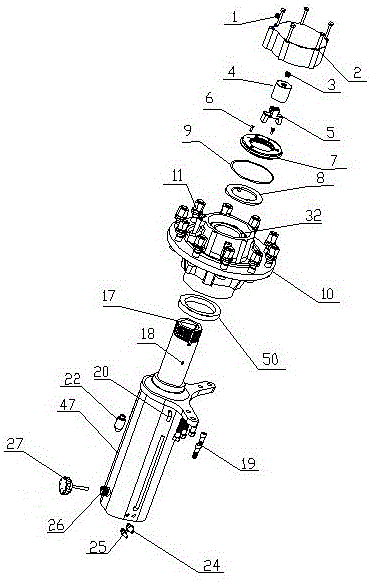

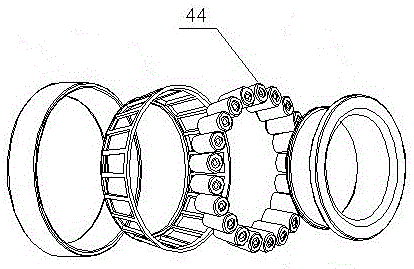

[0030] Such as figure 1 The shown maintenance-free hub assembly includes a hub 10 that is rotatably connected to the axle housing 47 through a tapered roller bearing 32. An oil seal 50 is installed at the inner end of the bearing hole of the hub 10, and an oil seal is installed at the outer end sequentially from the inside to the outside. The nut sealing ring 9, the shaft head locking piece 8 and the shaft head locking nut 7, the nut sealing ring 9 and the oil seal 50 seal the two ends of the bearing hole of the wheel hub 10, and the outer surface of the wheel hub 10 is also equipped with a cover bearing hole The shaft head cover 2.

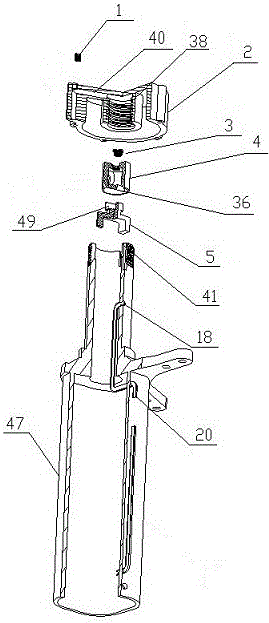

[0031] The wheel hub 10 is provided with an oil pipe with one end connected to the bearing hole, the axle housing 47 is provided with an oil drain hole 18 connecting the bearing hole of the wheel hub 10 and the inner cavity of the axle housing 47, and the axle head cover 2 is provided with two ends The oil passage 40 connecting the inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com