Controllable low-temperature mercury vapor source for ultrahigh vacuum system

A technology of ultra-high vacuum and mercury vapor, which is applied in the field of vacuum equipment and physical experiment equipment, and can solve problems such as no mercury vapor source technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

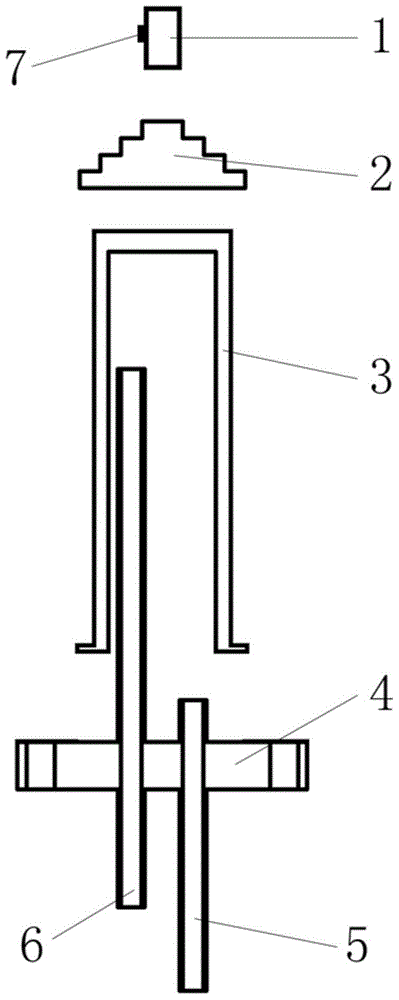

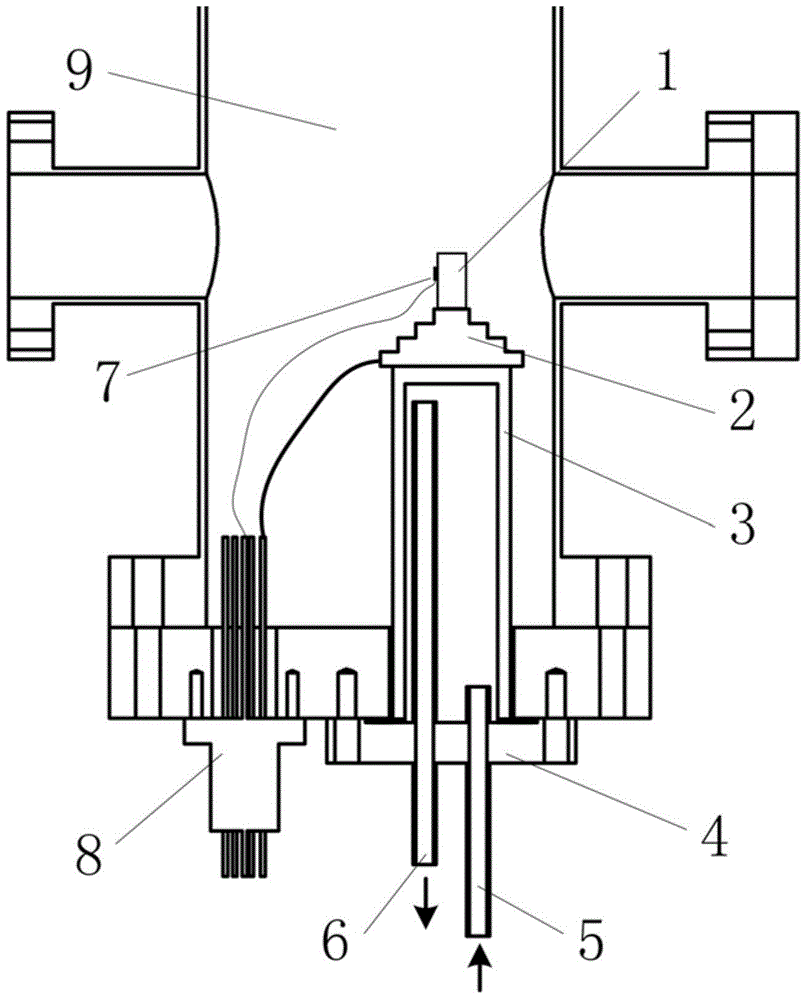

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

[0019] The ultra-high vacuum environment requires low outgassing rate of the internal components and can withstand the baking process necessary for the ultra-high vacuum preparation process. At the same time, the present invention involves refrigeration and heat transfer, and the thermal conductivity of related components must meet the requirements. Therefore, the mercury cup and the heat sink in this embodiment are made of oxygen-free copper, which has the advantages of high thermal conductivity and low vacuum outgassing rate. The temperature sensor is a vacuum Pt100 platinum thermal resistance. It adopts Aoleng's 6-stage vacuum TEC, which is trapezoidal, and the maximum cooling temperature difference between the upper and lower sides can reach 131°C. The water flange is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com