A method and system for on-line monitoring of the wall temperature of the vertical water-cooled wall of an ultra-supercritical boiler

An ultra-supercritical boiler and water-cooled wall technology, which is applied in the control system, indication of boiler working conditions, steam generation, etc., can solve problems such as inconsistencies in heat load uneven coefficients, avoid long-term over-temperature operation, prolong service life, The effect of improving the reliability of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

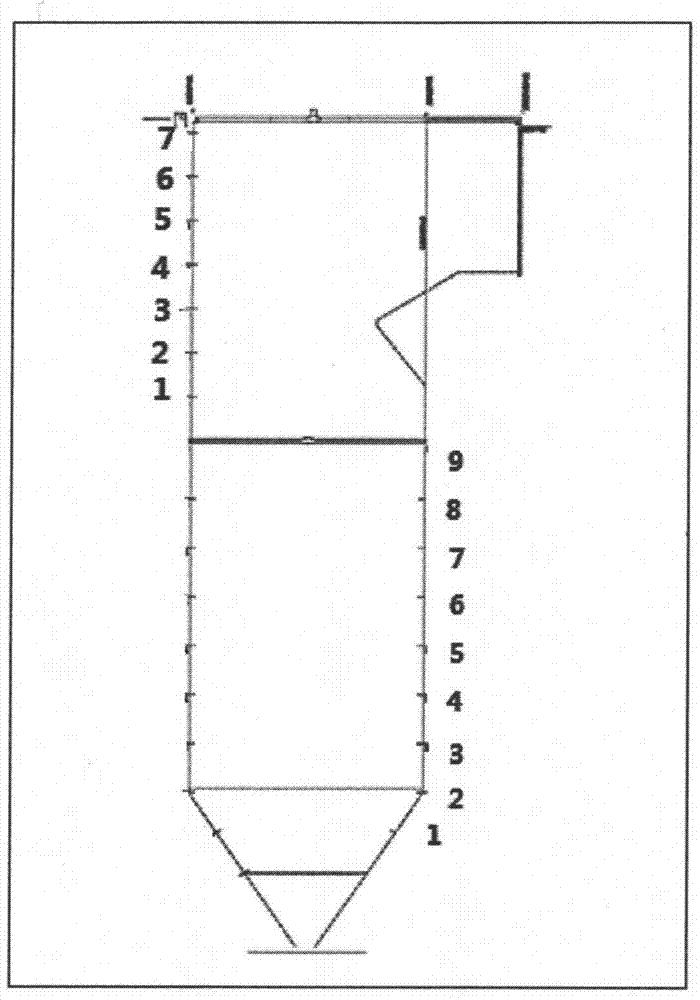

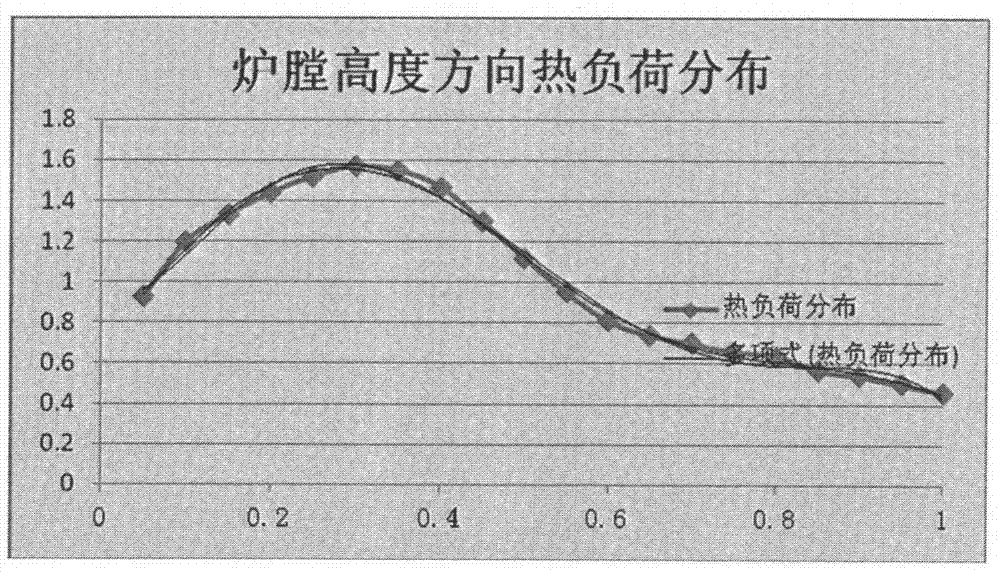

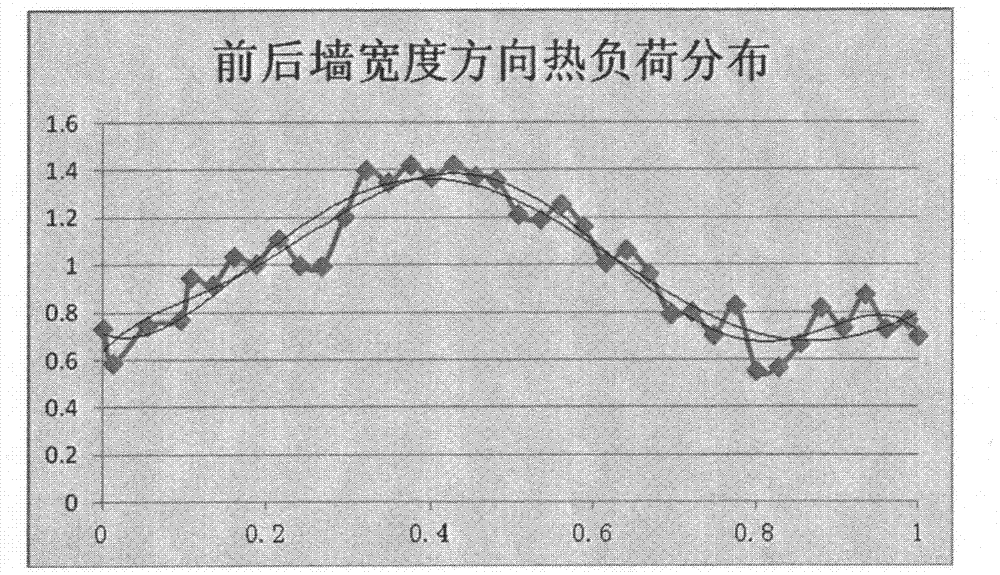

[0042] The invention provides an online detection method for the wall temperature of the vertical water-cooled wall of an ultra-supercritical boiler. The method is composed of the following three processes:

[0043] The first process: basic information calculation.

[0044] Step 1: Read boiler wall temperature measurement points and unit operating parameter information: the database server reads the temperature of the lower vertical water-cooled wall outlet tube wall measurement point through the factory-level monitoring device every Δt=0.5 minutes, and the upper vertical water-cooled wall outlet tube wall temperature. Wall measuring point temperature, load, main steam pressure, main steam flow, economizer outlet pressure, economizer outlet feed water temperature, coal mill combination and other parameter information.

[0045] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com