Blended type thick broad-bean sauce essence and preparation method thereof

A bean paste essence and blending technology, which is applied in the field of food flavor, can solve the problems of instability and short fragrance retention period, and achieve the effect of harmonious aroma, low cost and realistic flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

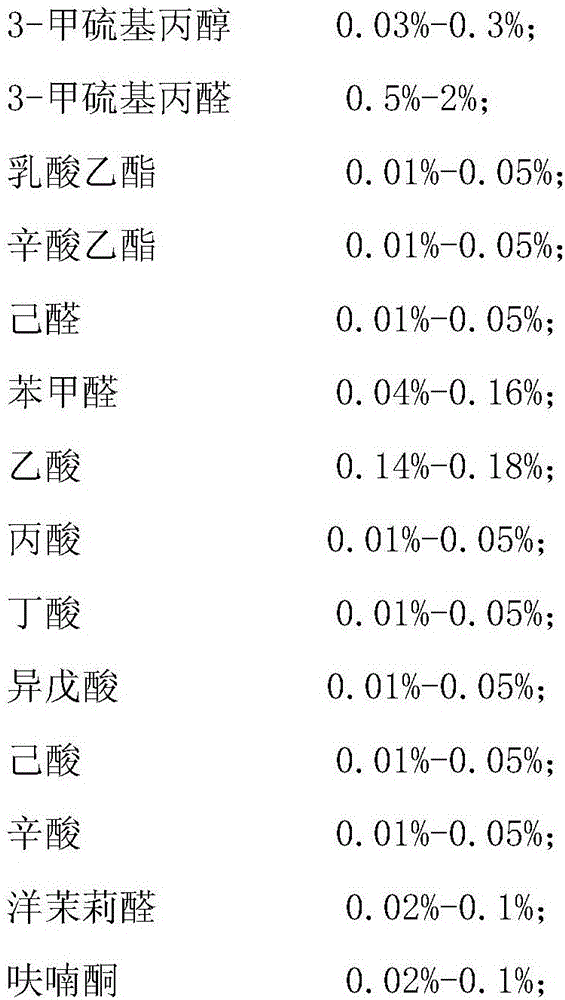

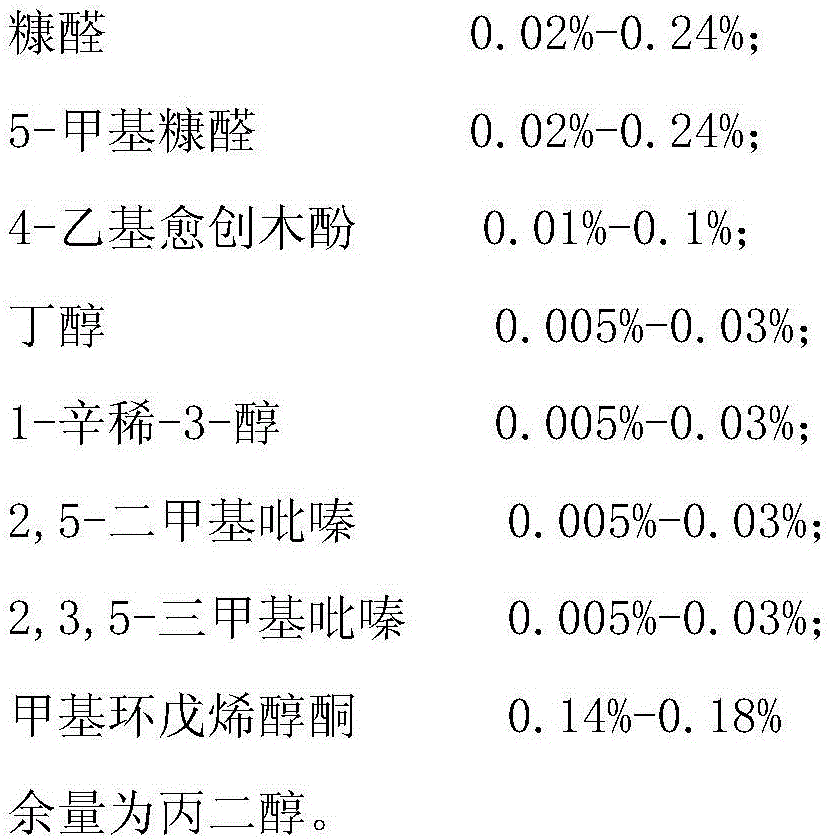

[0014] A blended bean paste essence is characterized in that, calculated by weight percentage, its composition and content are as follows:

[0015]

[0016]

[0017] Above-mentioned a kind of deployment type bean paste essence, its preparation process specifically comprises the following steps:

[0018] 3-methylthiopropanol, 3-methylthiopropanal, ethyl lactate, ethyl octanoate, hexanal, benzaldehyde, acetic acid, propionic acid, butyric acid, isovaleric acid, caproic acid, caprylic acid, jasmine Aldehyde, furanone, furfural, 5-methylfurfural, 4-ethylguaiacol, butanol, 1-octen-3-ol, 2,5-dimethylpyrazine, 2,3,5- Trimethylpyrazine, methylcyclopentenolone, and propylene glycol are uniformly mixed to obtain the bean paste essence.

Embodiment 2

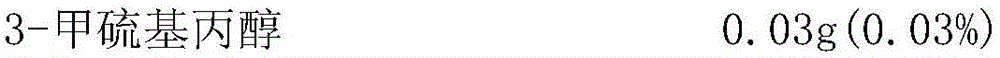

[0020] A blended bean paste essence is characterized in that, calculated by weight percentage, its composition and content are as follows:

[0021]

[0022] Above-mentioned a kind of deployment type bean paste essence, its preparation process specifically comprises the following steps:

[0023] 3-methylthiopropanol, 3-methylthiopropanal, ethyl lactate, ethyl octanoate, hexanal, benzaldehyde, acetic acid, propionic acid, butyric acid, isovaleric acid, caproic acid, caprylic acid, jasmine Aldehyde, furanone, furfural, 5-methylfurfural, 4-ethylguaiacol, butanol, 1-octen-3-ol, 2,5-dimethylpyrazine, 2,3,5- Trimethylpyrazine, methylcyclopentenolone, and propylene glycol are uniformly mixed to obtain the bean paste essence.

Embodiment 3

[0025] A blended bean paste essence is characterized in that, calculated by weight percentage, its composition and content are as follows:

[0026]

[0027] Above-mentioned a kind of deployment type bean paste essence, its preparation process specifically comprises the following steps:

[0028] 3-methylthiopropanol, 3-methylthiopropanal, ethyl lactate, ethyl octanoate, hexanal, benzaldehyde, acetic acid, propionic acid, butyric acid, isovaleric acid, caproic acid, caprylic acid, jasmine Aldehyde, furanone, furfural, 5-methylfurfural, 4-ethylguaiacol, butanol, 1-octen-3-ol, 2,5-dimethylpyrazine, 2,3,5- Trimethylpyrazine, methylcyclopentenolone, and propylene glycol are uniformly mixed to obtain the bean paste essence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com