Catalyst for preparing 1,3-propanediol by catalytic hydrogenation of 3-hydroxypropanal, preparation method and application thereof

A technology for the preparation of hydroxypropionaldehyde and hydrogen, which is applied in the preparation of hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Large-scale industrial applications and other issues, to achieve the effect of reducing the reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

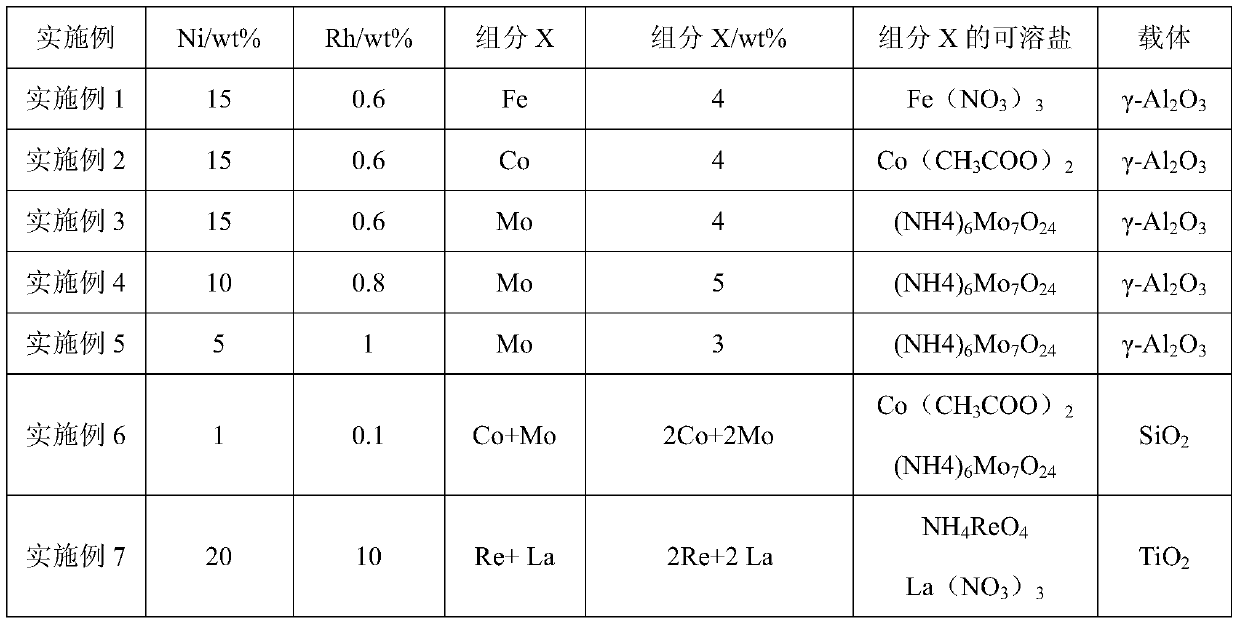

Examples

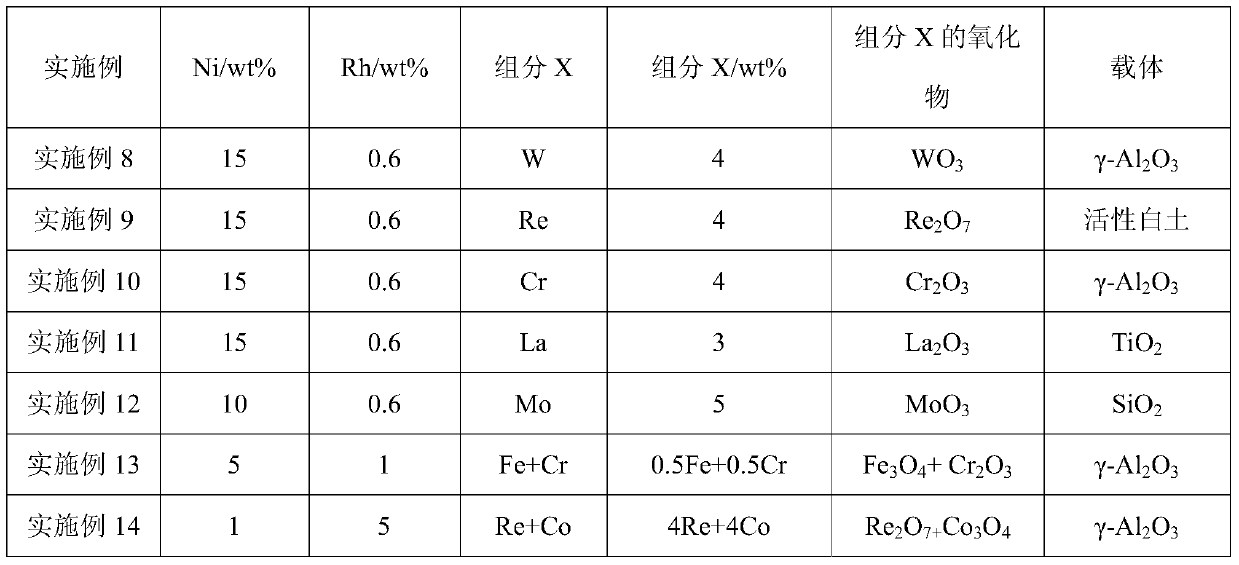

Embodiment 8-14

[0071] Embodiment 8-14 adopts mixing method to prepare 3-hydroxy propionaldehyde hydrogenation to prepare 1,3-propanediol catalyst:

[0072] (1) Take by weighing the oxide compound of nickel oxide, rhodium oxide, auxiliary agent X and carrier by metering ratio, join in the kneader, fully mix;

[0073] (2) adding concentration is 15wt% dilute nitric acid as binder, consumption is 5wt% of dry powder, adds polyethylene glycol (polymerization degree 3000) as structural aid, consumption is 4wt% of dry powder;

[0074] (3) The kneading rate is 20rpm, kneading 4h;

[0075] (4) Knead and mix evenly and extrude into strips, and the shearing is 5mm;

[0076] (5) Then dry at 100°C for 4h, and bake at 450°C for 6h.

[0077] Reduction pretreatment: put into the reactor after roasting, under the pressure of 0.2MPa, H 2 :N 2 = 1:2 mixed gas, the temperature is 360 ° C for 36 hours, after the reduction is completed, adjust to the conditions required for the reaction.

[0078] The catalys...

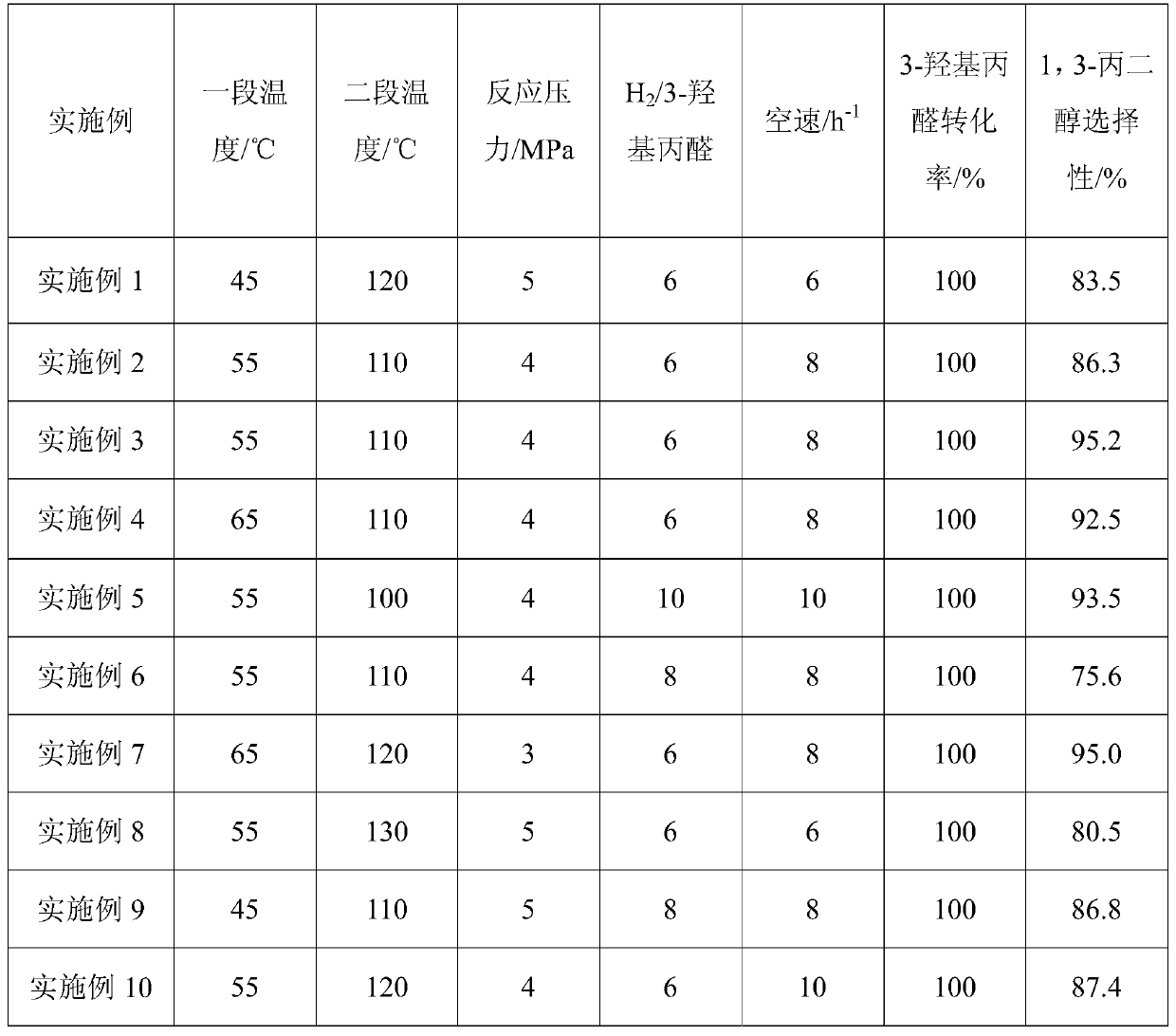

Embodiment 15

[0091] The hydrogenation catalyst in the prepared embodiment 3 is loaded into two-stage reactors connected in series, the two-stage reactors are filled with a mass ratio of 3:1, and the second stage is based on the Ni-Rh-X / A loaded multi-component The mass ratio of the catalyst is 1:8 and the sulfonic acid type cation exchange resin is added. Reduction at 360°C for 36h, and cooling down to 55°C after reduction. The 3-hydroxy propionaldehyde aqueous solution and H of raw material concentration 8wt% 2 After preheating, it enters the reactor. Reaction conditions: the first stage reaction temperature is 55°C, the second stage reaction temperature is 110°C, and the hourly space velocity of 3-hydroxypropanal aqueous solution is 8h -1 , H 2 : The molar ratio of 3-hydroxypropanal is 6:1, the reaction pressure is 4MPa, after 300h of reaction, the conversion rate of 3-hydroxypropanal is 99.9%, and the selectivity of 1,3-PDO is 95%. This example illustrates that the catalyst of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap