3d printing method

A 3D printing and material tank technology, applied in 3D object support structure, additive manufacturing, processing and manufacturing, etc., can solve the problem of easy blockage of the nozzle, and achieve the effect of ensuring uniform transportation, uniform distribution, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

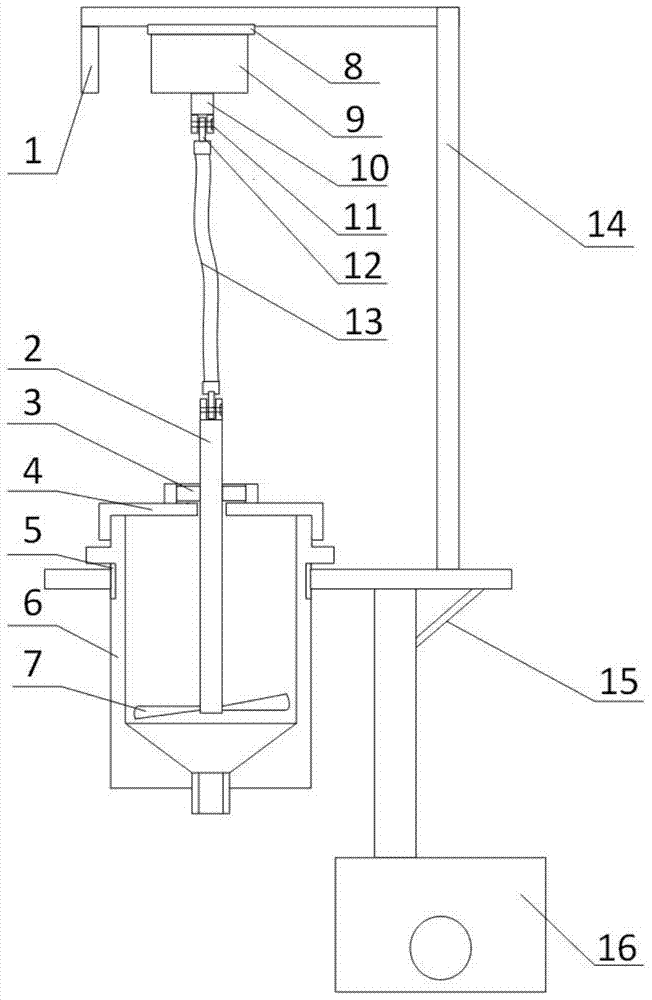

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0031] The present invention provides a 3D printing method, the 3D printing method comprising:

[0032] Step A: Make the material used for printing into a fluid and make it into a liquid;

[0033] Step B: transporting the fluid to the material tank;

[0034] Step C: Then, while the material is being discharged from the discharge port of the material tank, the fluid in the material tank is stirred. Stirring the material in the material tank can prevent the material from settling and ensure the uniform delivery of the material. Therefore, the problem of easy blockage of the nozzle in the field of low-temperature deposition 3D printing is solved.

[0035] like figure 1 As shown, the present invention adopts a kind of 3D printing equipment, to realize above-mentioned 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| connectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com