A special spreader for belts with large inclination angle

A technology with a large inclination angle and a belt is applied in the field of spreaders to achieve the effect of convenient production, avoidance of missed work and reduction of hoisting height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

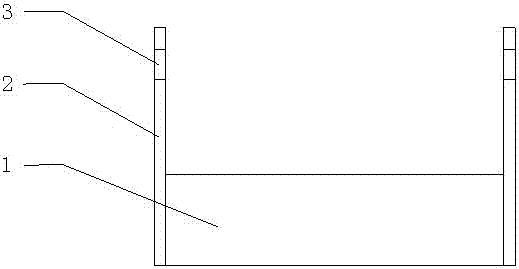

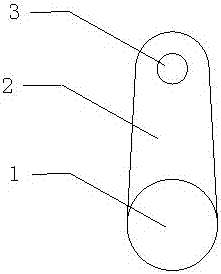

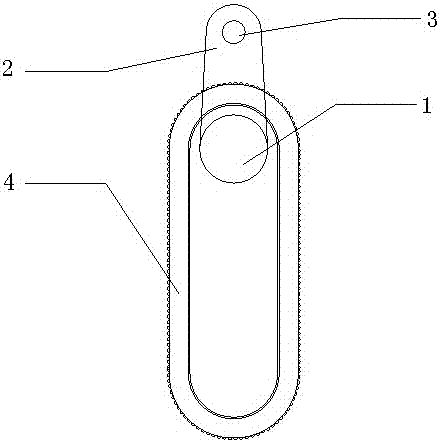

[0031] see now Figure 4 , Figure 4 It is a schematic diagram of the use state of the special sling for a large inclination angle belt according to the embodiment of the present invention. As shown in the figure, the hanging bearing unit includes a fixed panel 5, a movable panel 9, a flange hosting 11 and a main hosting 12, wherein: the main hosting 12 is a section of steel pipe, and a section of flange hosting 11 is welded on the top of both ends. The edges of the main hosting and the flange hosting are aligned, and one end of the main hosting and the flange hosting is provided with a through hole running through up and down; , its top is each provided with a lifting lug 3, the lower part of the fixed panel 5 is vertically welded with the main trustee and the flange trustee, the lower part of the movable panel 9 is provided with the same orifice with the same diameter as the master trustee and the flange trustee, and the main trustee and the flange are The escrow is passed...

Embodiment 2

[0039] The manufacturing method of the special sling for a large inclination angle belt of the present invention is as follows:

[0040] The manufacturing method of the special sling for a large inclination angle belt of the present invention is simple, and the materials used are relatively common. After directly purchasing steel plates from the market, they are made on site. The material is Q345 steel, and no heat treatment is required. Edge hosting, main hosting.

Embodiment 3

[0042] The use method of the special sling for a large-inclined belt of the present invention is as follows:

[0043] Step 1: Weld the flange hosting and the main hosting on the fixed panel

[0044] Step 2: After attaching the large inclination belt to the flange hosting and the main hosting, put the movable panel into the main hosting, and install the flange hosting on the side of the movable panel into the movable panel.

[0045] Step 3: Darken the other parts into place.

[0046] Step 4: Tighten the top rod nut to make the arc plate push against the flange of the belt with a large inclination to prevent it from sliding and scratching during the hoisting process.

[0047] Step 5: Install hoisting shackles on the lifting lugs of the fixed panel and movable panel, and use a crane to hoist the belt with a large inclination.

[0048] Step 6: After the large inclination belt is hoisted in place, pull out the beam pin, the trustee pin, loosen the top rod, and disassemble the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com