Method for preparing carbon-carbon composite material thermal insulation cylinder from soft felt

A technology of carbon-carbon composite material and insulation cylinder, which is applied in the field of insulation cylinder preparation, can solve the problems of high cost and long time, and achieve the effects of long service life, cost saving and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] (1) Select 5mm thick carbon fiber soft felt and 1mm thick flexible graphite paper for high temperature treatment at 1500°C, the volume density of carbon fiber soft felt is 0.14g / cm 3 .

[0027] (2) The solid content of 45% and the viscosity of phenolic resin of 10mpa.s are sprayed on both sides of the soft felt and one side of the graphite paper respectively. The surface is evenly sprayed and the amount of resin sprayed is 8kg.

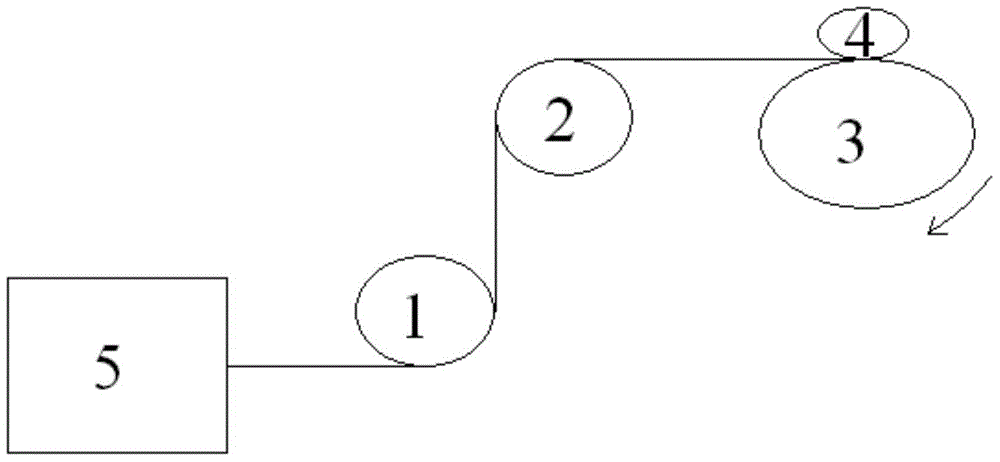

[0028] (3) if figure 1 As shown, the resin-sprayed soft felt and flexible graphite paper are respectively wound and formed on the graphite mandrel. The flexible graphite paper is only wound on the innermost and outermost layers of the product, and the soft felt is wound on 10 layers. .

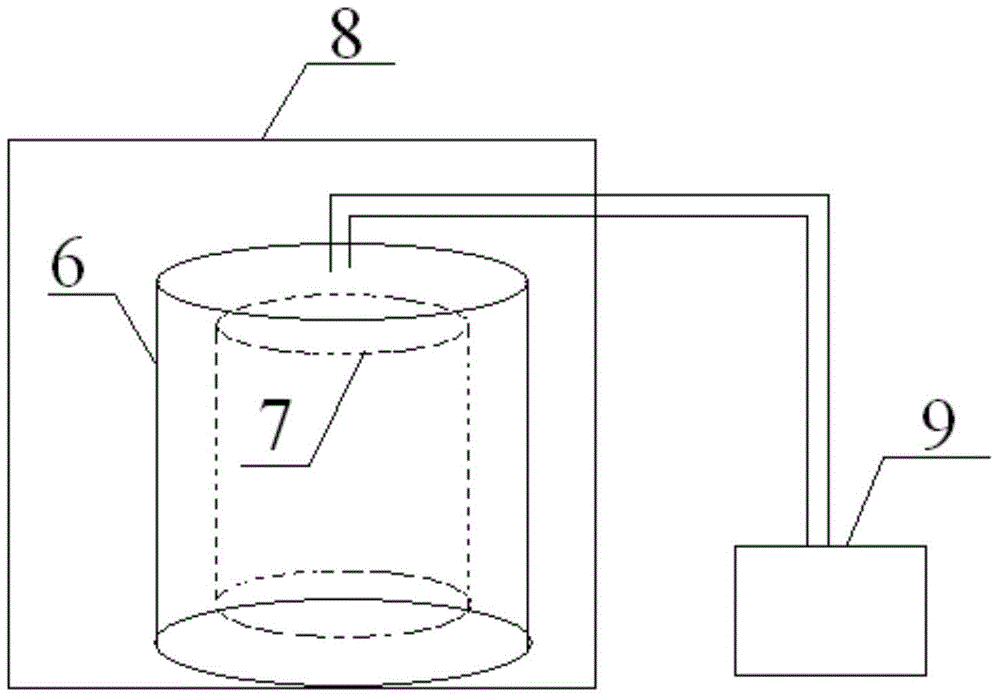

[0029] (4) if figure 2 As shown, put the coiled insulation cylinder into an oven for curing treatment. During the curing process, use a vacuum bag to seal the product and keep it in a vacuum state. The curing temperature is 160°C and the curing time is 4 ho...

example 2

[0033] (1) Select 10mm thick carbon fiber soft felt and 1mm thick flexible graphite paper for high temperature treatment at 1500°C, and the volume density of carbon fiber soft felt is 0.14g / cm 3 .

[0034] (2) The solid content of 45% and the viscosity of 10mpa.s phenolic resin are sprayed on both sides of the soft felt and one side of the graphite paper respectively. The surface is evenly sprayed, and the amount of resin sprayed is 15kg.

[0035] (3) if figure 1 As shown, the resin-sprayed soft felt and flexible graphite paper are respectively wound and formed on the graphite mandrel. The flexible graphite paper is only wound on the innermost and outermost layers of the product, and the soft felt is wound on 5 layers. .

[0036] (4) if figure 2 As shown, put the wound insulation cylinder into an oven for curing treatment. During the curing process, use a vacuum bag to seal the product and keep it in a vacuum state. The curing temperature is 180°C and the curing time is 2 ...

example 3

[0040] (1) Select 12mm thick carbon fiber soft felt and 1mm thick flexible graphite paper for high temperature treatment at 2000°C, and the volume density of carbon fiber soft felt is 0.15g / cm 3 .

[0041] (2) The solid content of 45% and the viscosity of 10mpa.s phenolic resin are sprayed on both sides of the soft felt and one side of the graphite paper respectively. The surface is evenly sprayed, and the amount of resin sprayed is 30kg.

[0042] (3) if figure 1 As shown, the resin-sprayed soft felt and flexible graphite paper are respectively wound and formed on the graphite mandrel. The flexible graphite paper is only wound on the innermost and outermost layers of the product, and the soft felt is wound on 5 layers. .

[0043] (4) if figure 2 As shown, put the wound insulation cylinder into an oven for curing treatment. During the curing process, use a vacuum bag to seal the product and keep it in a vacuum state. The curing temperature is 180°C and the curing time is 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com