A kind of pile driver and pile pressing method thereof

A pile driver and fuselage technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of the construction process cannot be carried out smoothly, the construction efficiency is low, etc., to facilitate large-scale promotion, improve efficiency, and facilitate installation. The effect of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

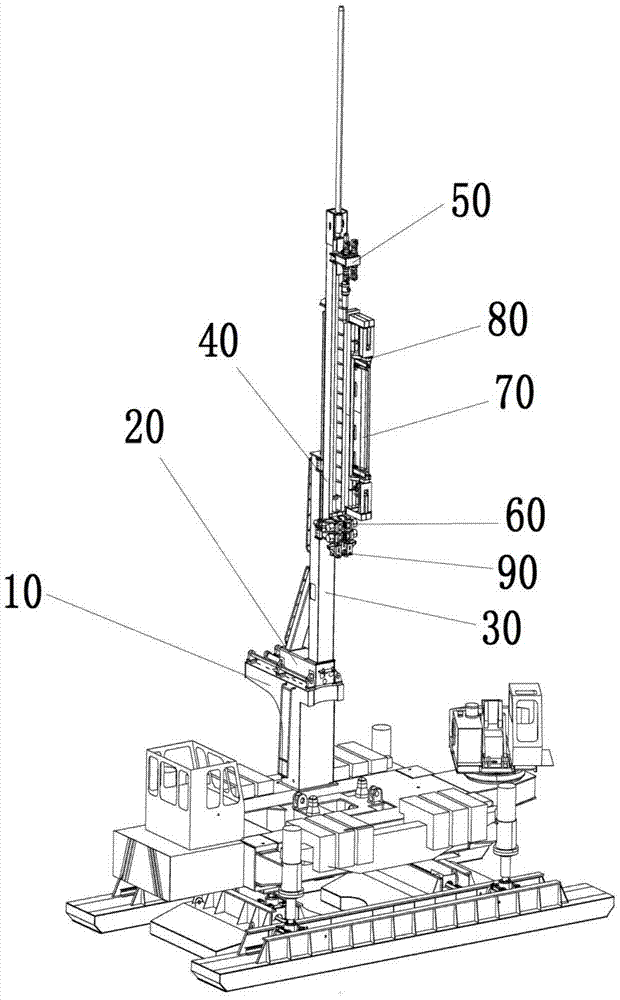

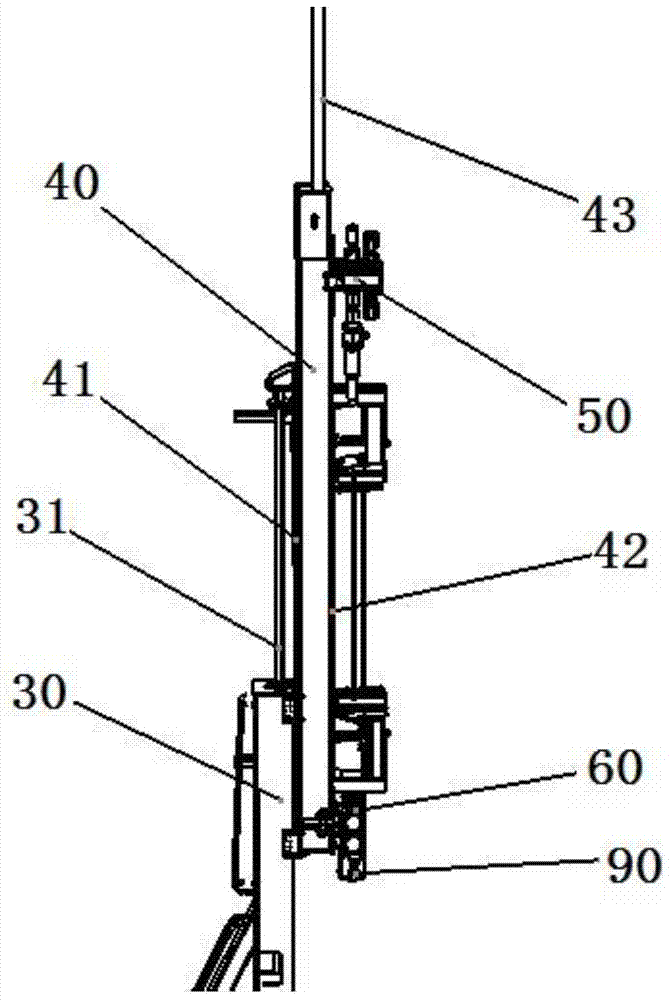

[0041] The invention provides a pile driver, with reference to figure 1 , which includes a pile driver body and a fixed platform 10, a beam 20, an auxiliary beam 30, a main beam 40, a power head 50, a clamper 60, a vertical drilling rod box 70, Manipulator 80 and detachment preventer 90.

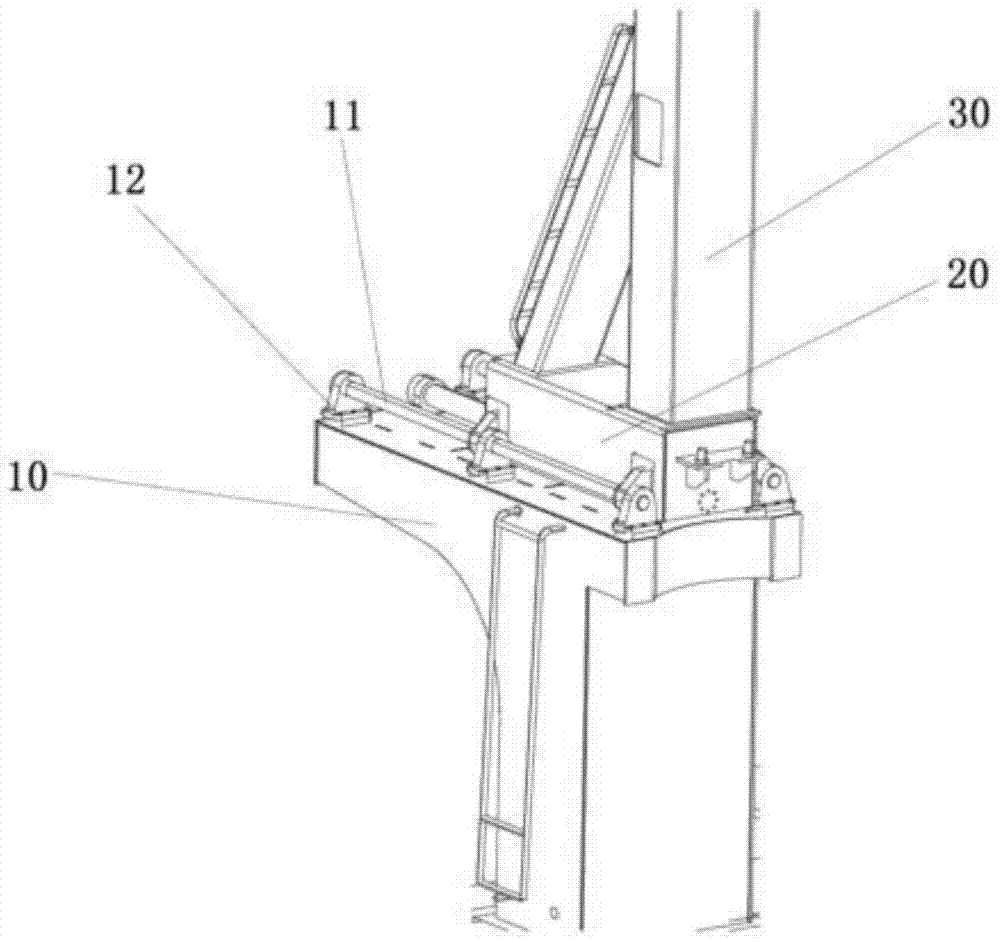

[0042] refer to figure 2 , The fixed platform 10 is fixed on the plane of the pile driver body through screw connection, which can be easily disassembled. The height of the fixed platform 10 is more than 2 meters, which avoids the interference of the upward movement of the clamping pile box and solves the problem of insufficient space. The upper surface of fixed platform 10 is provided with translation guide rail shaft 11 and translation seat 12, and transla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com