An unmanned dredger for processing industrial sludge and its working method

A technology for industrial sludge and dredgers, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc. Low efficiency and other problems, to achieve high dredging efficiency and prevent odor emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

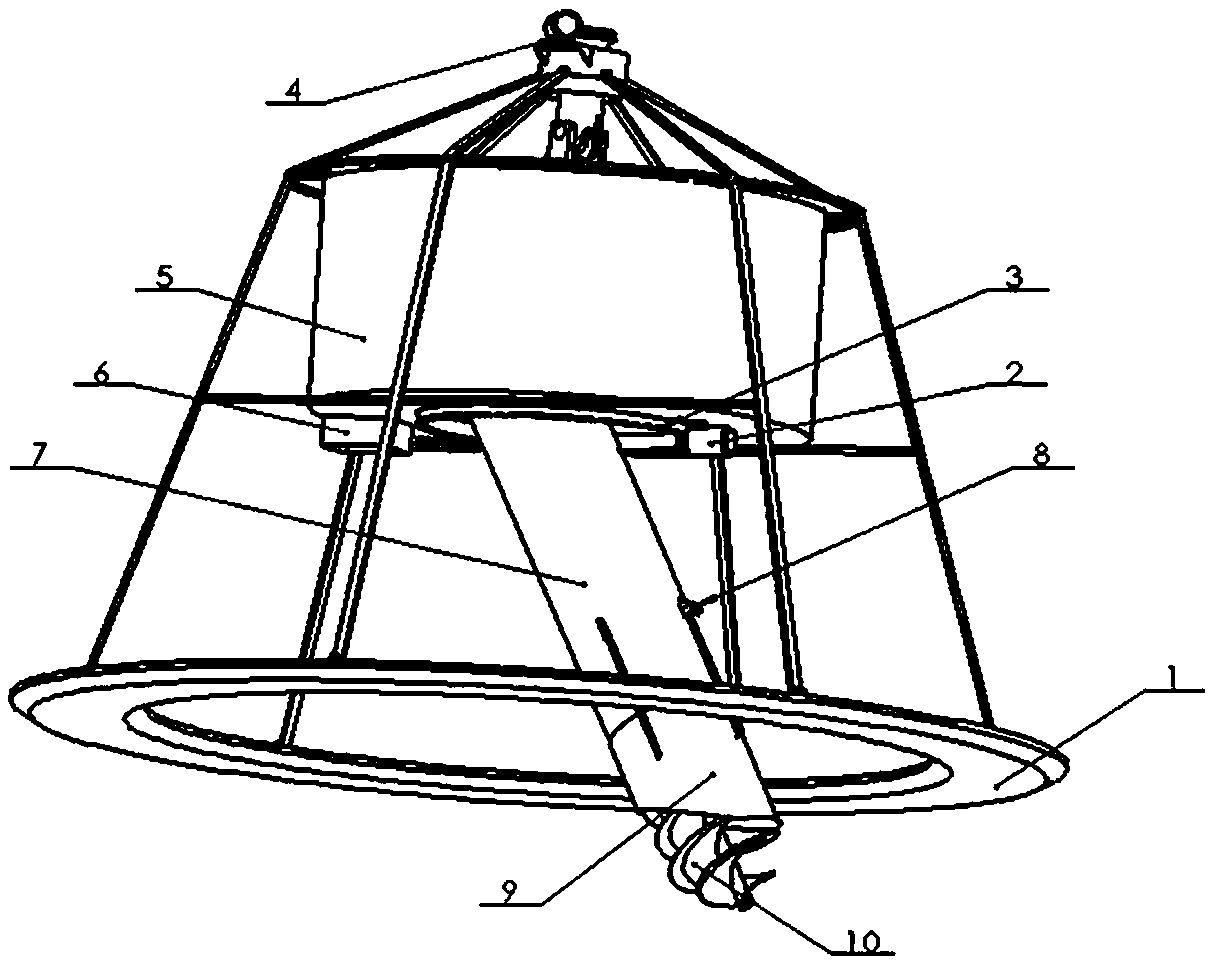

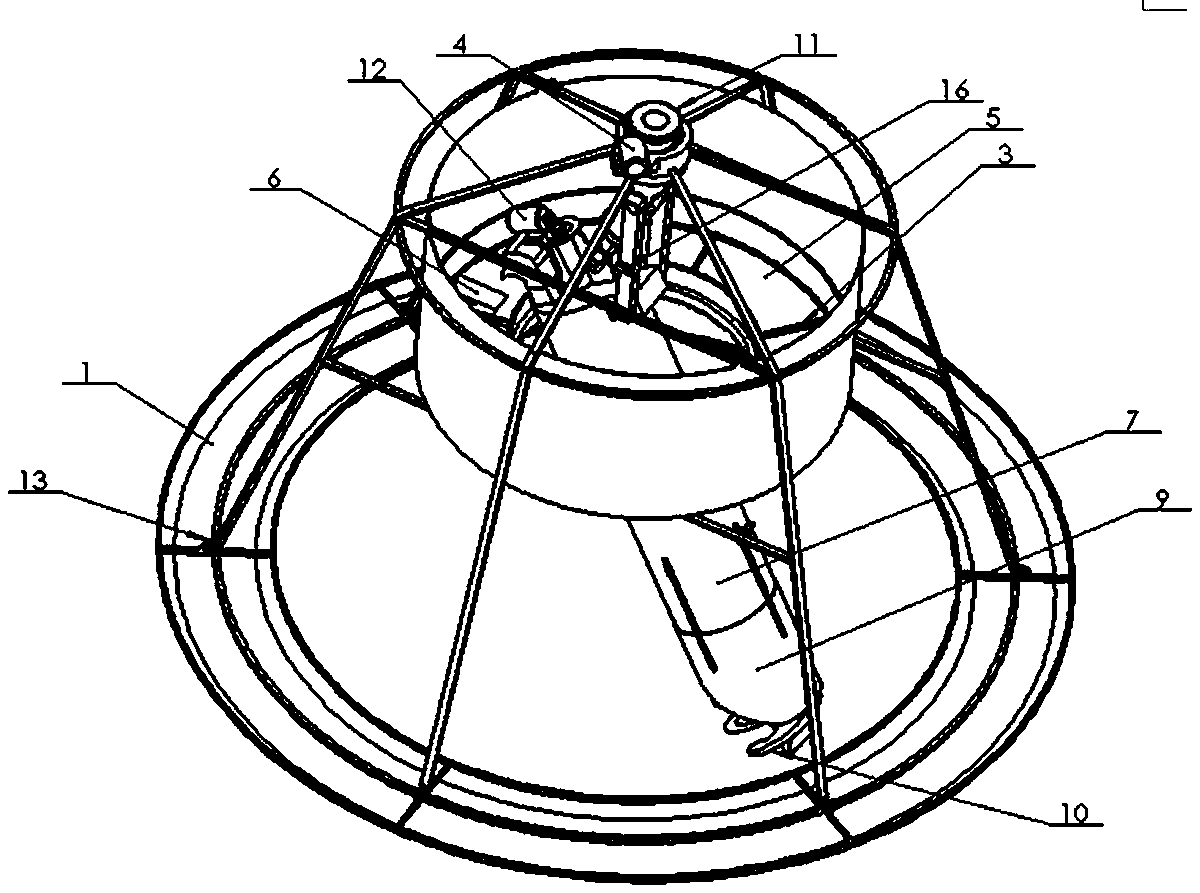

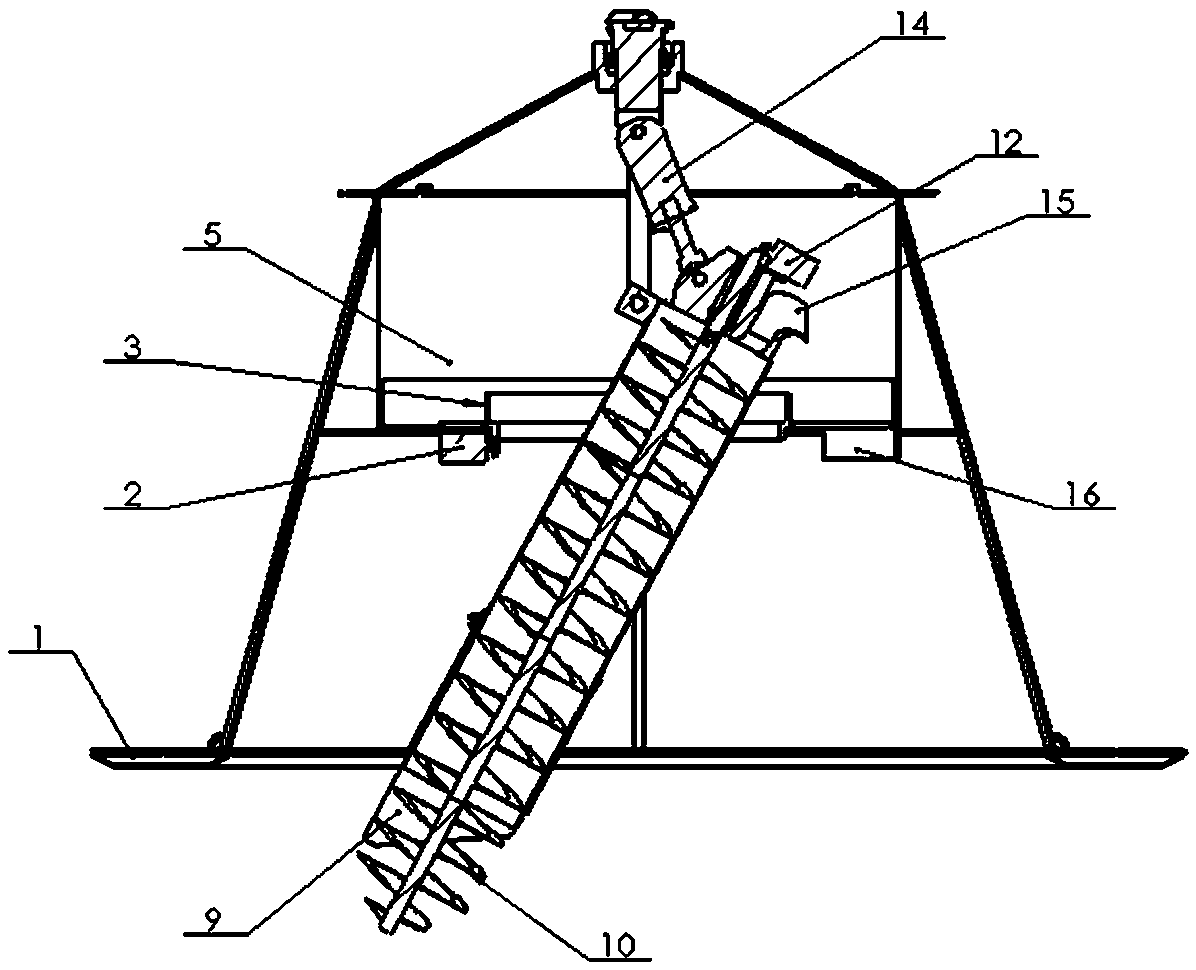

[0037] figure 1 , 2 Schematic diagram of the structure of a dredger for processing industrial sludge, image 3 Cutaway view of an unmanned dredger for treating industrial sludge and stench;

[0038] The present invention is following structure:

[0039] A yurt-shaped outer frame composed of a circular chassis 1 and connecting beams, wherein the chassis 1 adopts a flat and wide ring with a flat bottom surface, so that the dredger maintains a relatively stable body during dredging work and is not easy to sink. The overall frame of the dredging mainly provides the supporting force on the sludge. The chassis 1 has six collars 13, three for applying upward supporting force, and three for applying horizontal moving force. The frame remains stationary during dredging.

[0040] The temporary sludge storage tank 5 is composed of a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com