Integrated structure and construction method of external wall thermal insulation reinforced composite board and thermal insulation wall

An external wall thermal insulation and composite board technology, which is applied to thermal insulation, walls, building components, etc., can solve the problems of cumbersome construction of infill walls, poor fire protection level, complicated on-site production, etc., and achieves thermal insulation effect and long life. The effect of thermal insulation is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

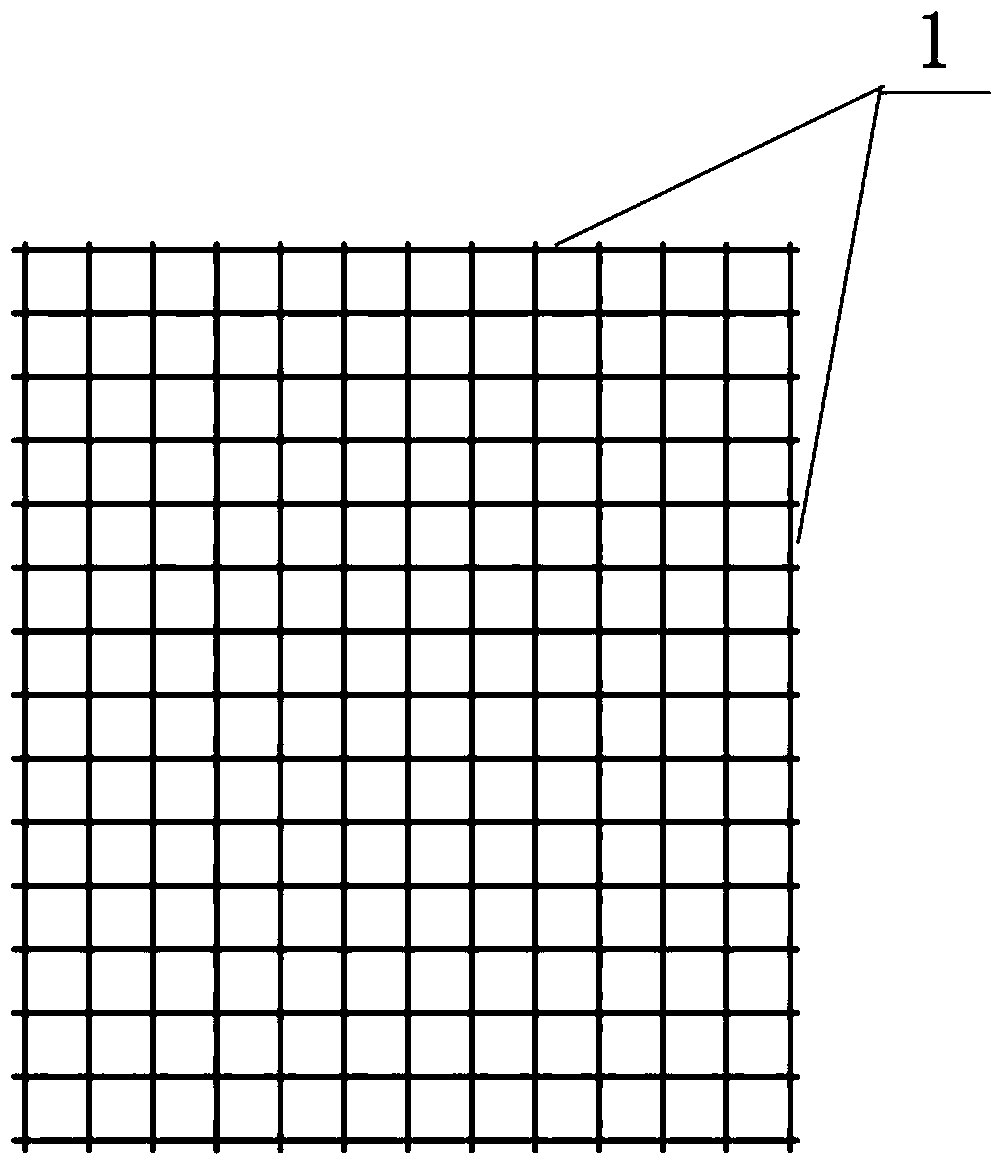

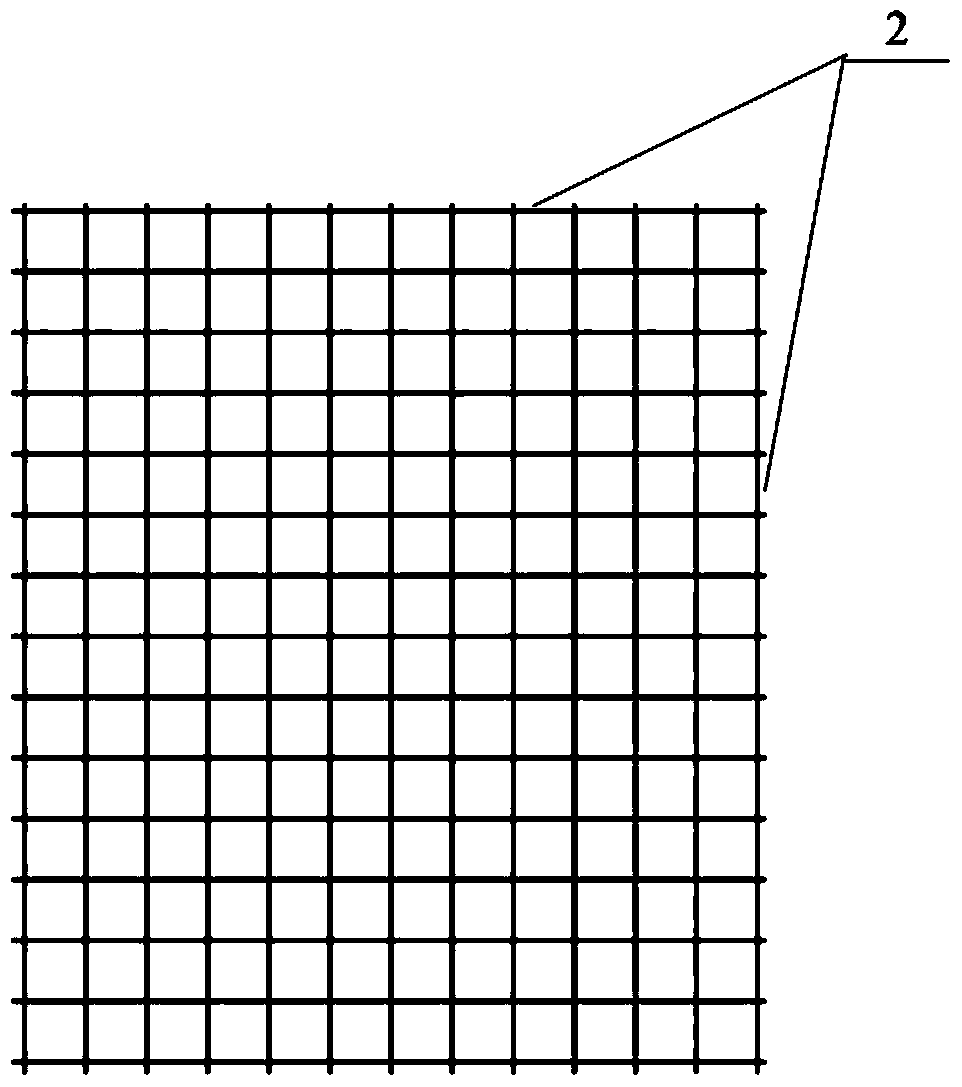

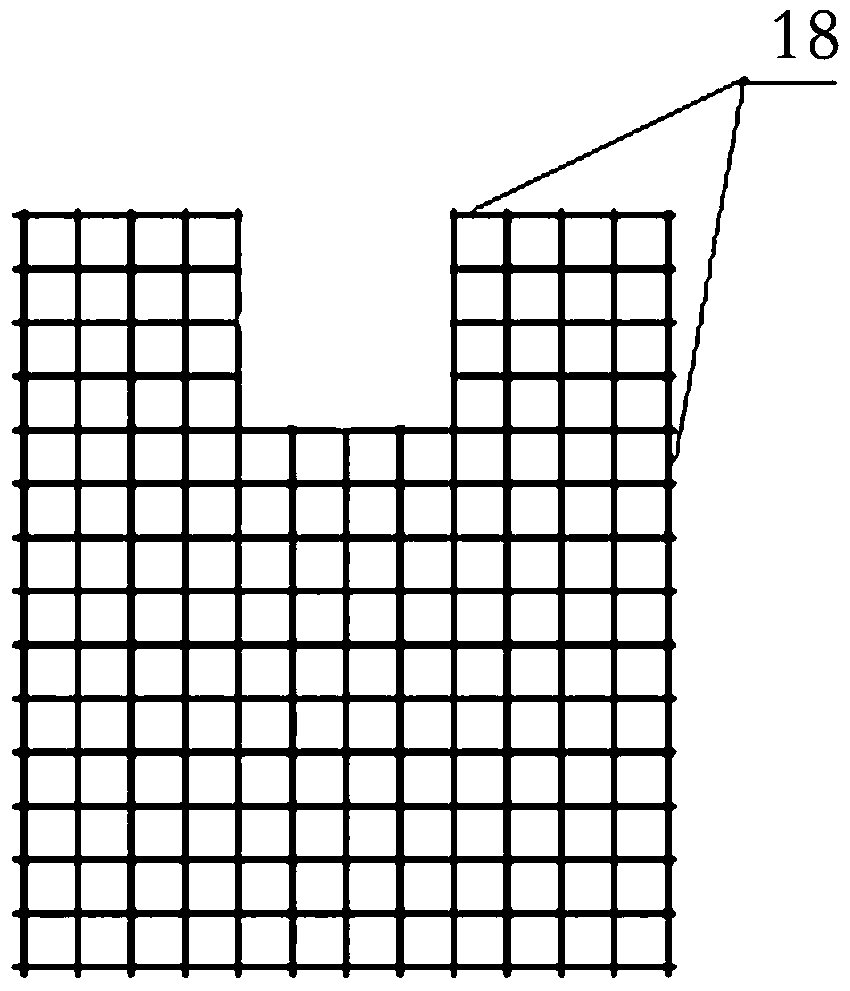

[0047] Vertical section drawing of standard external wall thermal insulation and reinforced composite panel (refer to Figure 6 , in the accompanying drawings: 1. Standard steel welded mesh A; 2. Standard steel welded mesh B; 3. Fixed piece; 4. Connecting steel; 5. Standard insulation board; layer; 8, standard external wall insulation and reinforced composite board; 10, groove;). Standard external wall insulation reinforced composite board (length*width*thickness: 1000mm*900mm*90mm): including standard reinforced insulation board 6 (see Figure 5 ) and lightweight concrete pouring and pressing protective layer 7; the standard reinforced insulation board 6 includes two parallel welded mesh sheets A and B of the same size and shape (referred to as mesh sheets A and B, the same below; mesh The length*width of sheet A and B: 1000mm*900mm) and a standard insulation board 5 matching its structure and size (the specification is 1000mm*900mm*40mm), the distance between mesh A and B i...

Embodiment 2

[0049] Vertical section drawing of standard external wall thermal insulation and reinforced composite panel (refer to Figure 7 , In the accompanying drawings: 1. Standard steel bar welded mesh A; 2. Standard steel bar welded mesh B; 3. Fixed piece; 4. Connecting steel bar; 5. Standard insulation board; layer; 8, standard external wall insulation and reinforced composite board; 14, chute). Standard external wall insulation reinforced composite board (length*width*thickness: 1000mm*1000mm*90mm): including standard reinforced insulation board 6 (see Figure 5 ) and lightweight concrete pouring and pressing protective layer 7; the standard reinforced insulation board 6 includes two parallel welded mesh sheets A and B of the same size and shape (referred to as mesh sheets A and B, the same below; mesh The length*width of sheet A and B: 1000mm*1000mm) and a standard insulation board 5 matching its structure and size (the specification is 1000mm*1000mm*50mm), the distance between m...

Embodiment 3

[0051] Vertical section drawing of standard external wall thermal insulation and reinforced composite panel (refer to Figure 6 ). Standard external wall insulation and reinforced composite board (length*width*thickness: 1500mm*1000mm*105mm): including standard reinforced insulation board 6 (see Figure 5 ) and lightweight concrete pouring and pressing protective layer 7; the reinforced insulation board 6 includes two parallel welded mesh sheets A and B of standard steel bars of the same size and shape (referred to as mesh sheets A and B, the same below; mesh sheets The length*width of A and B: 1500mm*1000mm) and a standard insulation board 5 matching its structure and size (the specification is 1500mm*1000mm*50mm), the distance between mesh A and B is 100mm; mesh A, B is placed on both sides of the standard insulation board 5, and the mesh sheets A and B are horizontally and vertically provided with a plurality of connecting steel bars 4 passing through the standard insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com