Agricultural machine belt of meridian cord fabric structure

A technology for seed cord fabric and agricultural machinery belt, applied in the direction of V-shaped belt, mechanical equipment, belt/chain/gear, etc. Lateral stiffness and ability to withstand pressure, increase flexibility and load capacity, improve stretch and service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

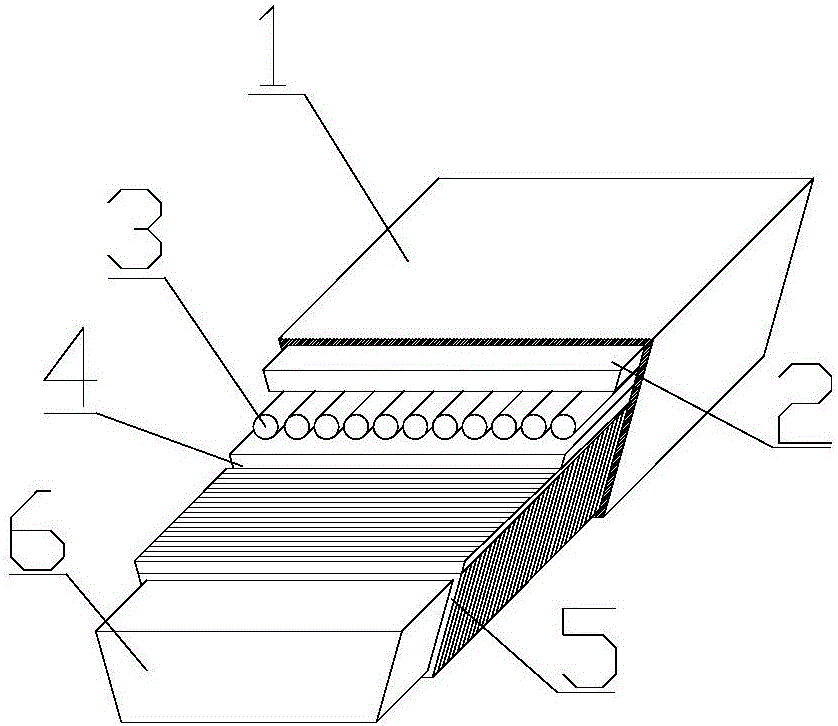

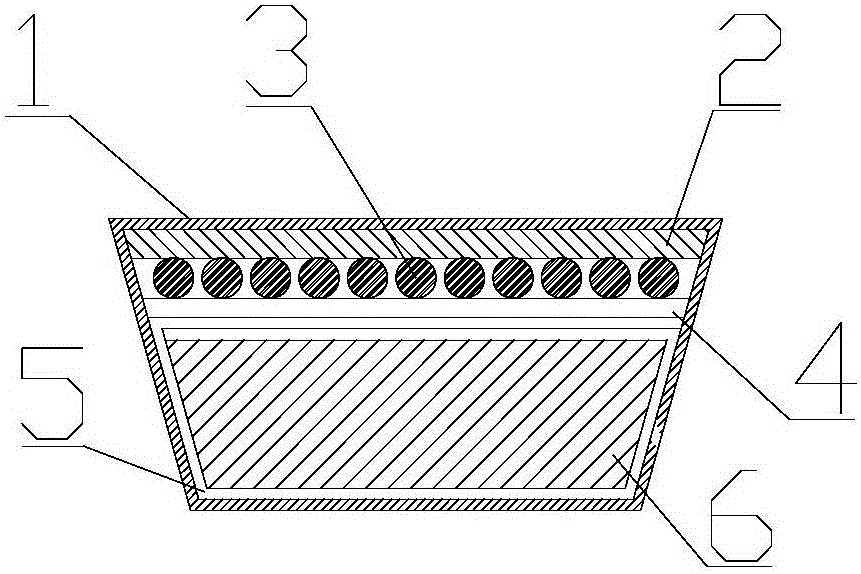

[0024] This embodiment provides an agricultural machinery belt with a radial cord structure, the agricultural machinery belt includes a wrapping layer 1, a top glue 2, a strength layer 3, a buffer rubber 4, a meridian ply layer 5, Compression glue 6 and adhesive glue for bonding meridian ply 5 and compression glue 6; The top glue 2 is bonded on the top of the strength layer 3, the buffer glue 4 is bonded below the strength layer 3, and the cushion glue 4 The lower part is bonded with a compression glue 6 wrapped circumferentially by the meridian ply 5, and the top of the compression glue 6 is covered with two layers of meridian ply 5; the meridian cords in the meridian ply 5 are arranged in parallel, It forms an angle of 90° with the center line of the agricultural machinery belt.

[0025] The present embodiment also provides a preparation method for the above-mentioned agricultural machinery belt with a meridian cord structure, comprising the following steps:

[0026] (1) Un...

Embodiment 2

[0032] This embodiment provides an agricultural machinery belt with a radial cord structure, the agricultural machinery belt includes a wrapping layer 1, a top glue 2, a strength layer 3, a buffer rubber 4, a meridian ply layer 5, Compression glue 6 and adhesive glue for bonding meridian ply 5 and compression glue 6; The top glue 2 is bonded on the top of the strength layer 3, the buffer glue 4 is bonded below the strength layer 3, and the cushion glue 4 The lower part is bonded with a compression glue 6 wrapped circumferentially by the meridian ply 5, and the top of the compression glue 6 is covered with two layers of meridian ply 5; the meridian cords in the meridian ply 5 are arranged in parallel, It forms an included angle of 90° with the center line of the agricultural machinery belt; the meridian ply layer includes a meridian cord and a cord glue, and adjacent meridian cords are isolated by the cord glue; the cords used in the meridian cord 5 are nylon 66 cords cord or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com