Electromagnetic microvalve device

A microvalve and electromagnetic technology, applied in the field of microfluidics, can solve the problems of unfavorable microfluidics system integration and miniaturization, expensive manufacturing process, large volume of iron core coils, etc., and achieve good electrical connection stability, perfusion production Convenience, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

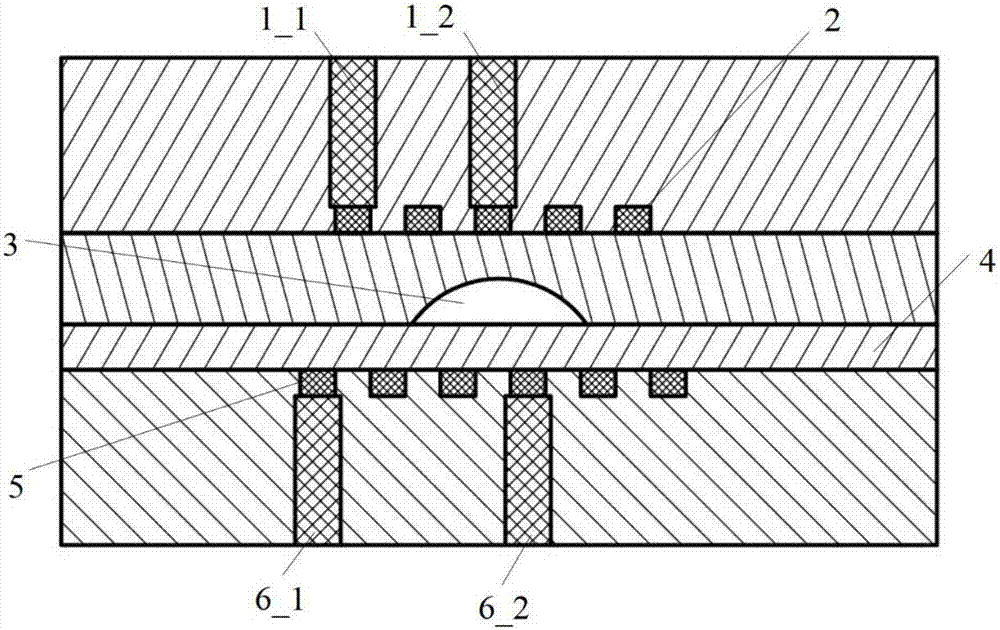

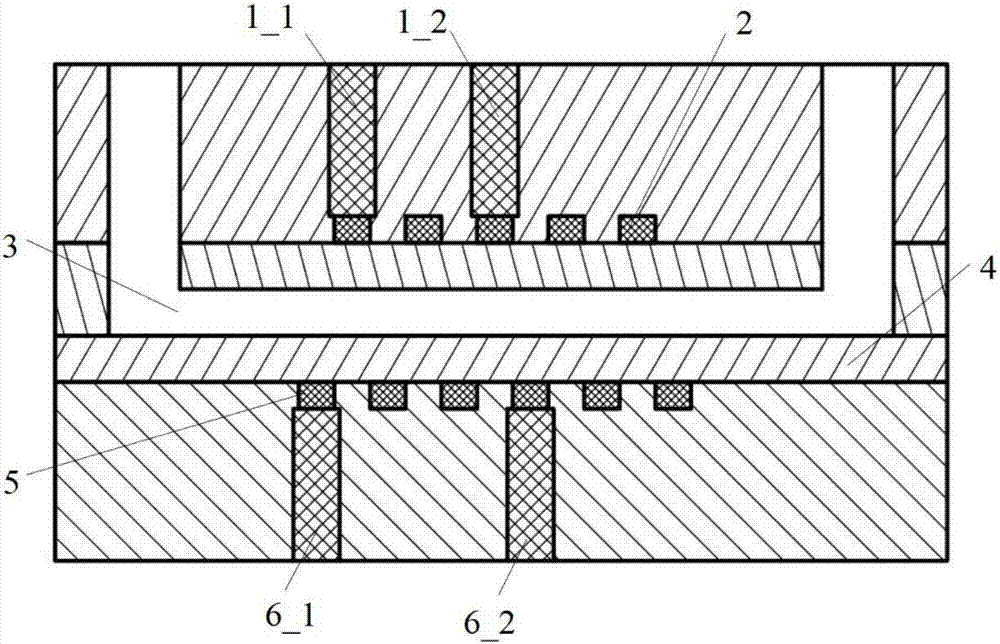

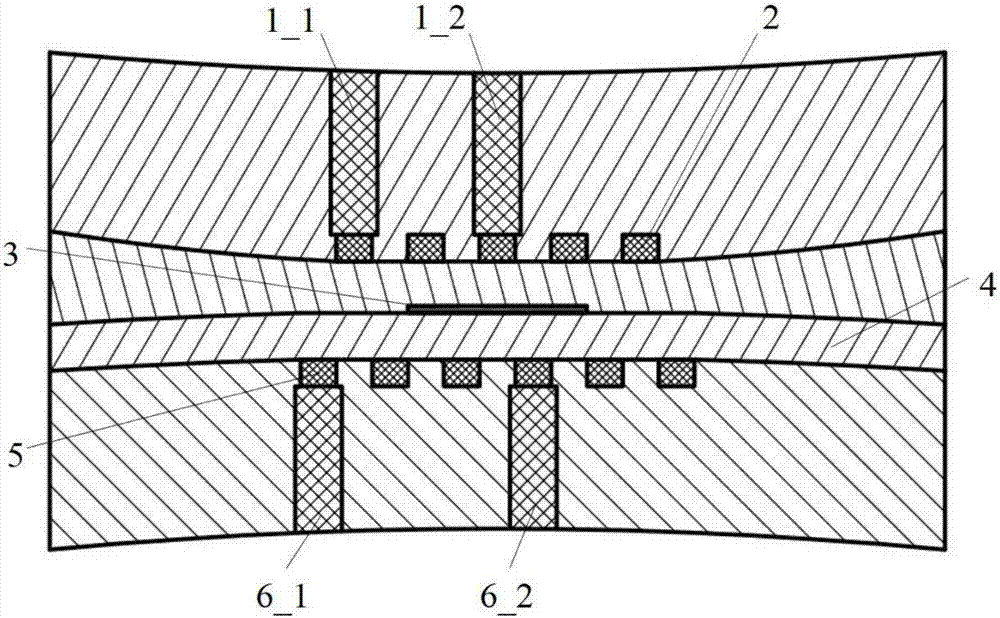

[0025] figure 1 It is a schematic cross-sectional view of an electromagnetic microvalve device in an open state according to an embodiment of the present invention; figure 2 yes figure 1 The longitudinal sectional schematic diagram of the electromagnetic microvalve device shown in the open state; refer to Figure 1~2 , the device includes: a sample reagent channel 3, a first liquid metal helical coil microchannel 5 filled with room temperature liquid metal, a second liquid metal helical coil microchannel 2 filled with room temperature liquid metal, and a flexible film 4;

[0026] The first liquid metal helical coil microchannel 5 and the second liquid metal helical coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com