Underwater low-disturbance separation device

A separation device, low-disturbance technology, applied in the directions of mines, offensive equipment, weapon types, etc., can solve the problems that the warhead is difficult to maintain the vertical state, the separation device has a large separation stroke, and there is lateral moment, etc., to reduce the impact, The effect of short separation time and no hysteresis in response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

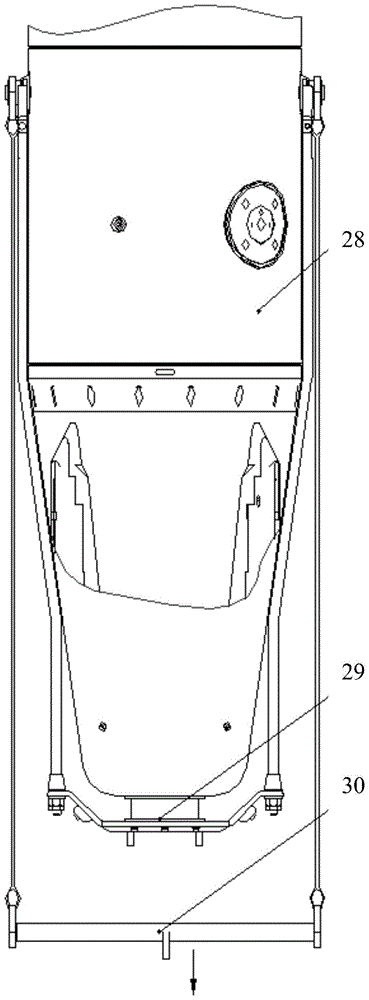

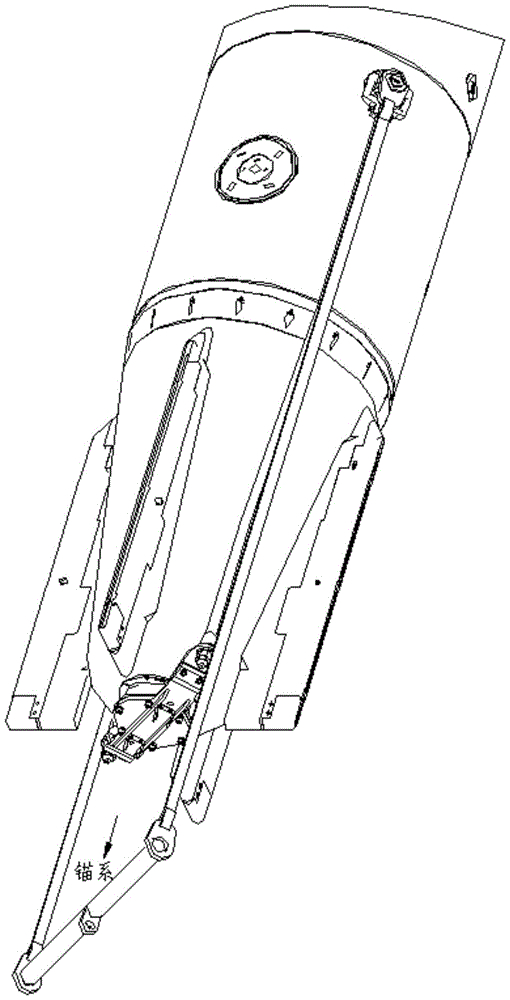

[0030] as attached figure 1 and 2 As shown, the present invention provides an underwater low-disturbance separation device. The separation device 29 connects the mooring system 30 and the floating warhead 28 into one body. The mooring system 30 makes the floating warhead 28 hover at a designated position underwater.

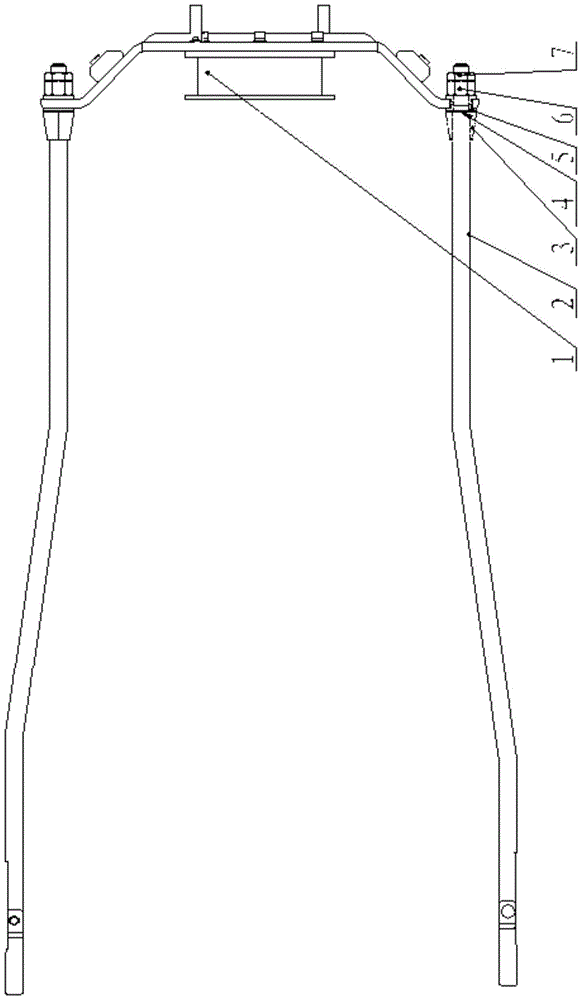

[0031] as attached image 3 As shown, the separation device 29 includes: a separation component 1 , a connecting rod set 2 , a sheath 3 , an adjusting washer 4 , an isolation washer 5 , a lock nut 6 and a lock nut 7 . The separating part 1 of the device is connected with the mounting surface of the tail of the floating warhead through screws, and an O-shaped sealing ring 10 is installed between the separating part 1 and the floating warhead for sealing. The clamping frame 25 of the connecting rod group 2 is connected with the mooring seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com