Strip coal pillar stability testing device and testing method

A technology of stability test and strip coal pillar, which is applied in measuring device, using stable tension/pressure to test material strength and strength characteristics, etc., can solve the problem of ignoring the coupling effect of coal and rock mass size effect, which is difficult and has large errors. and other problems, to achieve the effect of simple assembly, convenient operation and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

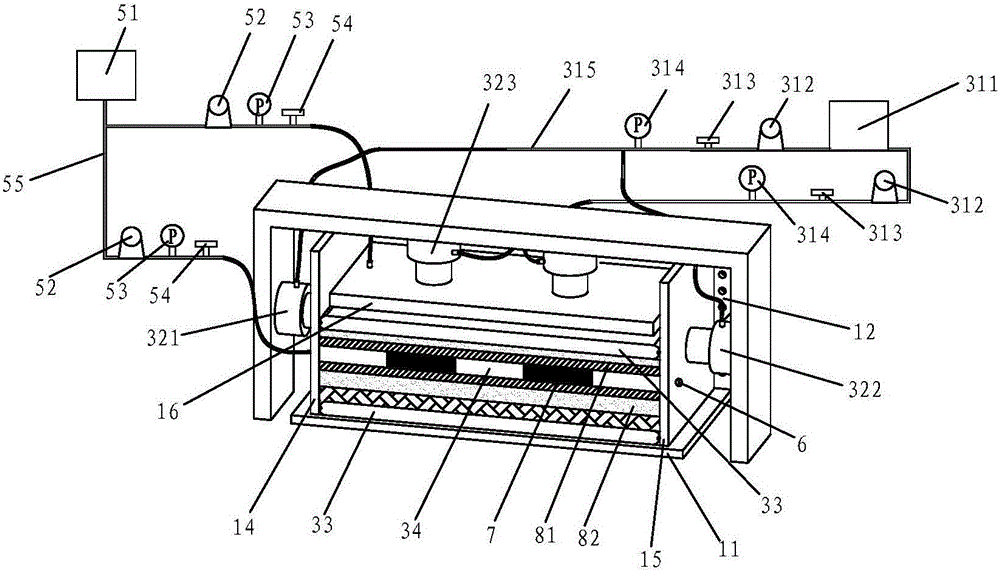

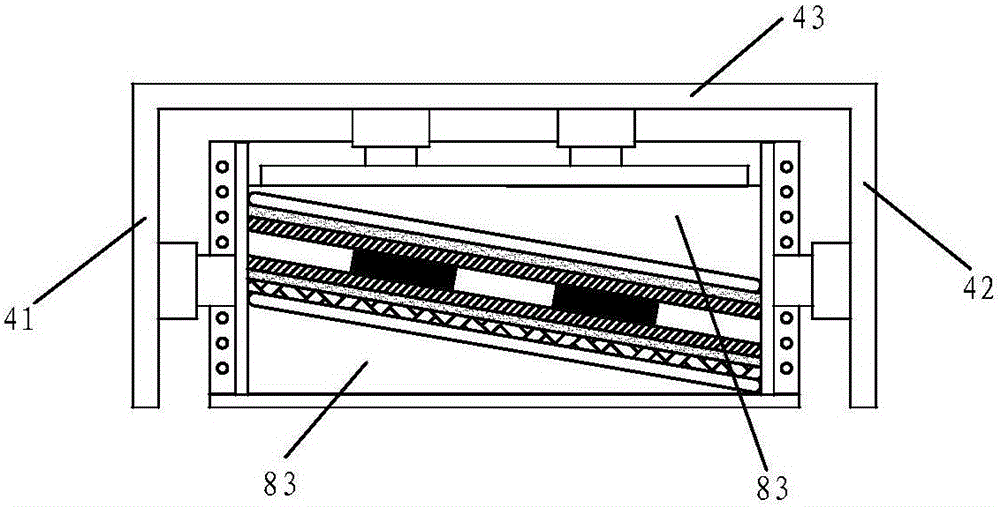

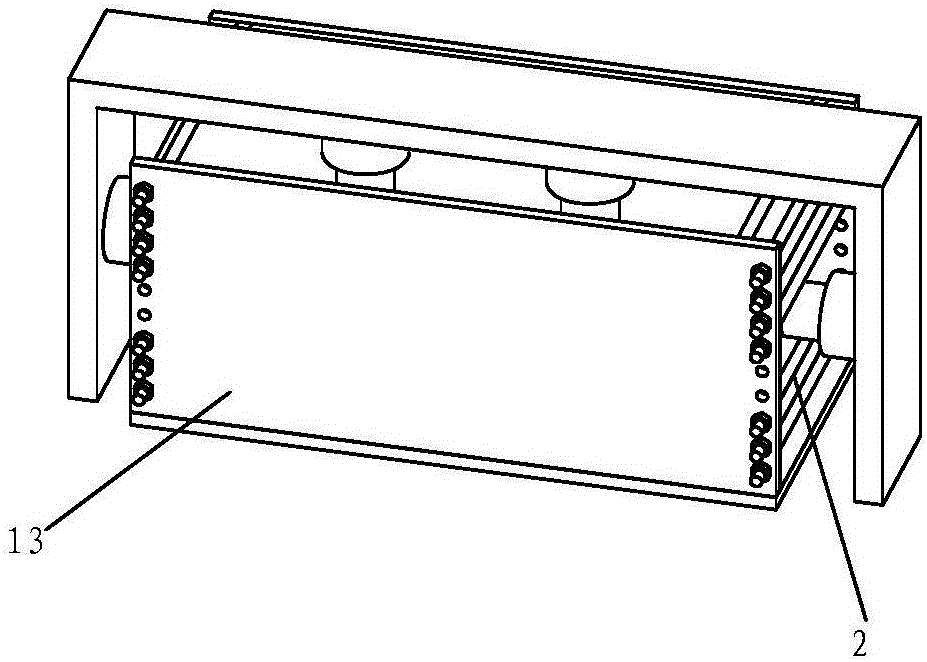

[0034] Such as Figure 1 to Figure 6As shown, this embodiment provides a strip coal pillar stability test device, including a test box, a loading unit, a test frame and a water supply unit. The test box includes a lower board 11 , a rear side board 12 , a front side board 13 , a left side board 14 , a right side board 15 and an upper board 16 . The left edge, the right edge and the lower edge of the left side plate 14 are provided with a groove 9, and a cylindrical rubber strip is assembled and connected in the groove 9, and the left edge, the right edge and the lower edge of the right side plate 15 are provided with a groove 9, A cylindrical rubber strip is assembled and connected in the groove 9 . The left side plate 14 or the right side plate 15 are provided with a test connection hole 6, and the signal line of the sensor and the water pipe 55 connected to the water bladder 34 pass through the test connection hole 6 to connect to the computer. After laying the required sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com