Portable intelligent waveform recording four-channel partial discharge detector

A waveform recording, intelligent technology, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of accelerated insulation defects, residual insulation phenomenon, equipment failure power accidents, etc., to achieve the effect of simple trigger loop and economical detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

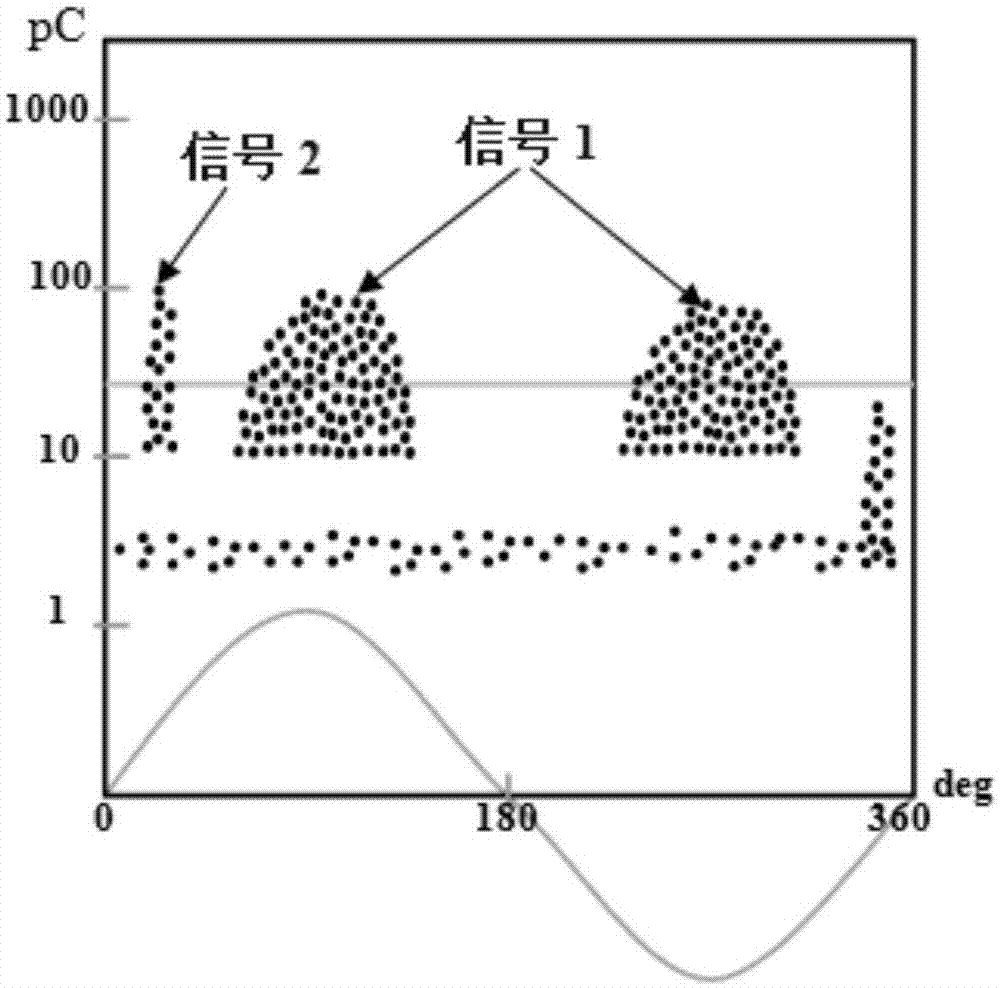

[0058] The trigger gate value is automatically set by the software, and the trigger value automatically set by the software is △t 1 , Δt 2 , Δt 3 three groups, of which

[0059] The trigger value automatically set by the software is △t 1 , the a signal is triggered,

[0060] The trigger value automatically set by the software is △t 2 , the b signal is triggered,

[0061] The trigger value automatically set by the software is △t 3 , the signals a and b are triggered,

[0062] Signal classification can be realized by automatically setting the interval trigger threshold value, as shown in the attached Figure 11-14 shown.

Embodiment 2

[0064] By manually setting the threshold value of the trigger interval, two trigger lines T1 and T2 are manually set, and the set trigger line determines the trigger threshold interval △t 1 , then △t 1 The signal in the interval is triggered, that is, the waveform b is triggered, as shown in the attached Figure 15-16 shown.

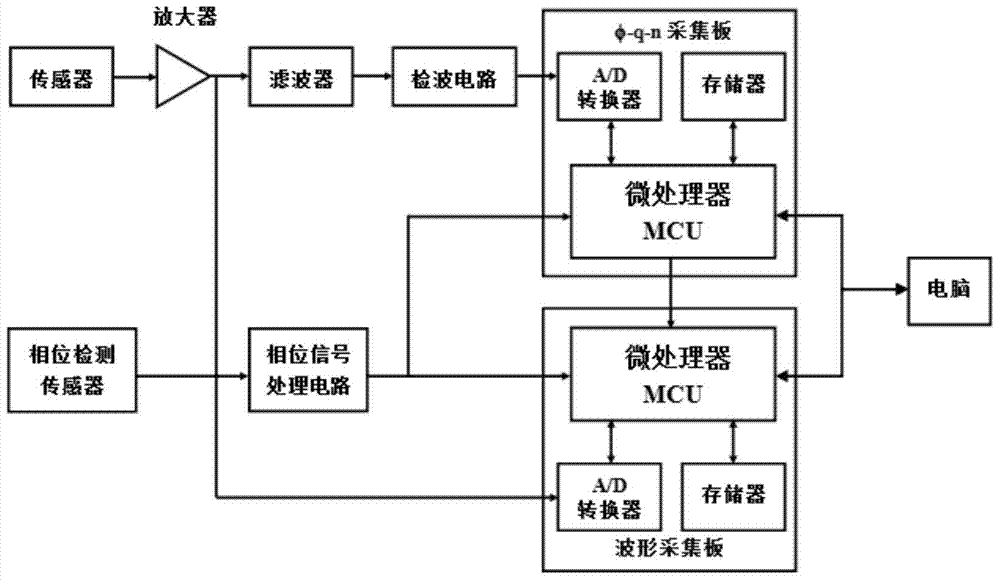

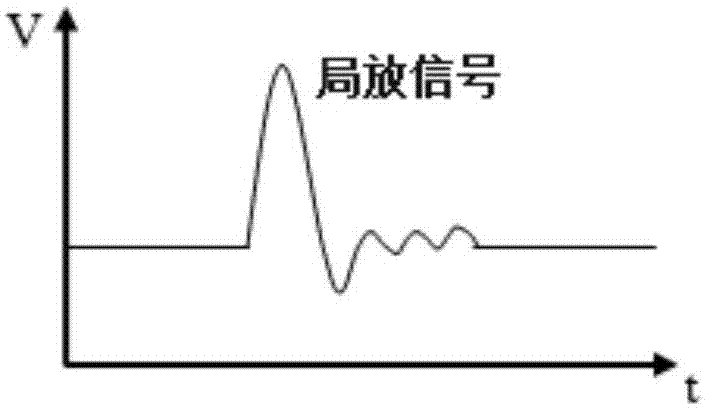

[0065] The working principle of the present invention is: the sensor collects the signal on the cable line, the analog signal collected is amplified by the amplifier and then transmitted to the first waveform acquisition board, and the A / D of the data is performed by the microprocessor MCU in the first waveform acquisition board Convert and store, and transmit to the computer to display various signal waveforms. At the same time, set multiple trigger thresholds according to the original waveform. The set multiple trigger values are transmitted to the second waveform acquisition board, and the second waveform acquisition board performs conditional sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com