Display panel and manufacturing method thereof

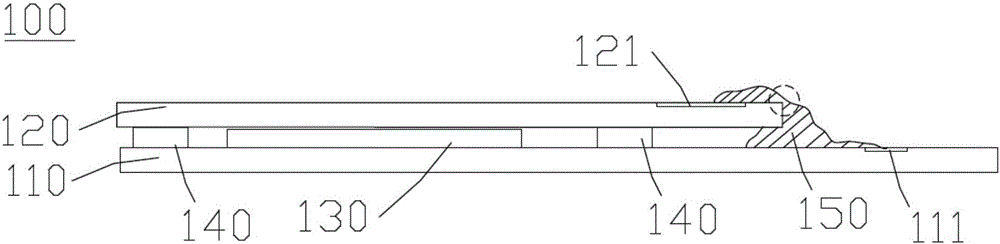

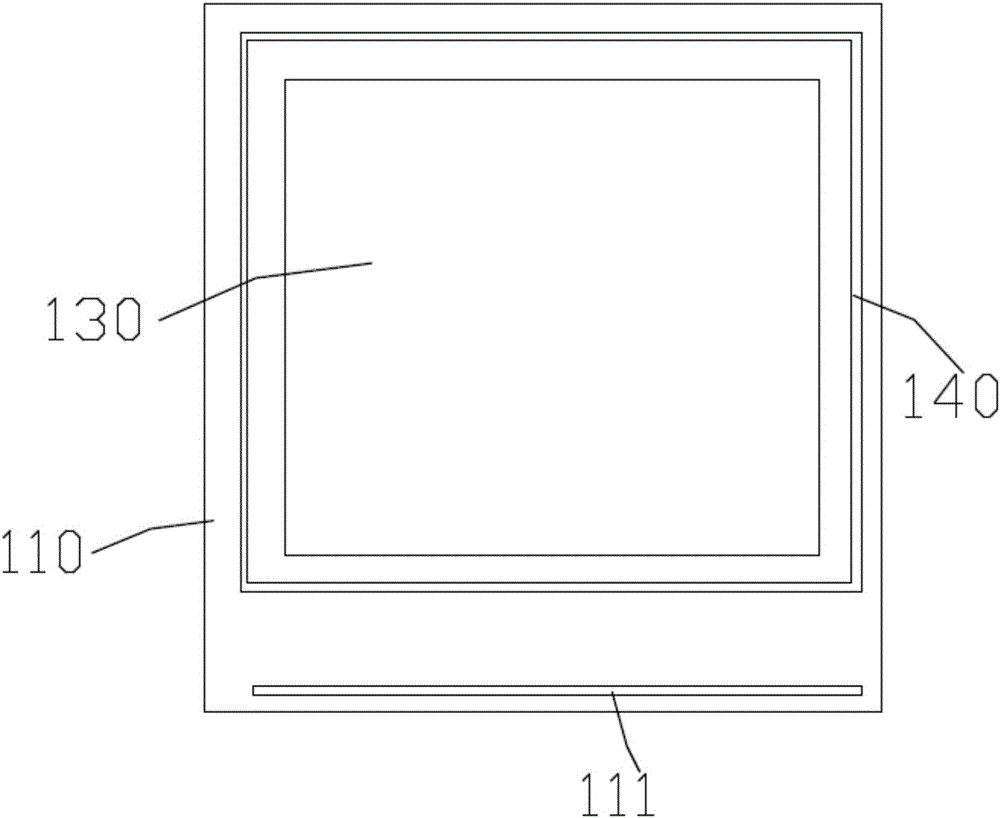

A display panel and manufacturing method technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of poor electrostatic discharge effect and the breaking width of conductive adhesive 150, achieve better electrostatic discharge ability, improve climbing ability, The effect of enhancing the strength of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

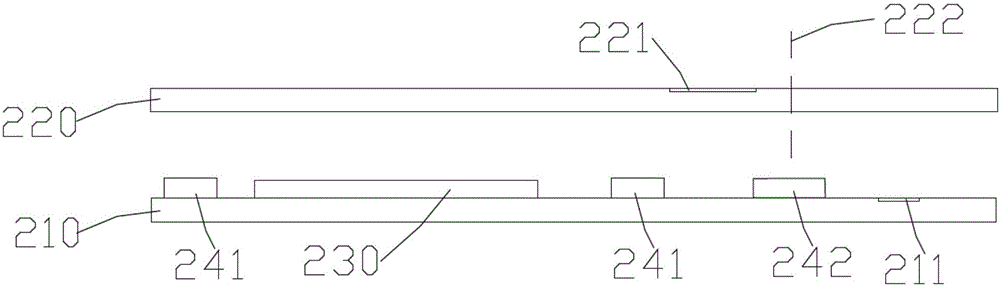

[0042] Figure 3 to Figure 6 It is a schematic diagram of each stage of the manufacturing method of the first embodiment of the display panel of the present invention, please refer to Figure 3 to Figure 6 .

[0043] like image 3 As shown, a first substrate 210 and a second substrate 220 are provided, the first substrate 210 has a conductive unit 211, and the second substrate 220 has at least one conductive pad 221;

[0044] A liquid crystal layer 230 is disposed on the first substrate 210;

[0045] A sealant layer comprising a first frame portion 241 and a second frame portion 242 is formed on the first substrate 210, the first frame portion 241 surrounds the liquid crystal layer 230, and the second frame portion 242 is located on the second substrate. On the cutting path 222, that is, the first frame sealing part 241 and the second frame sealing part 242 in this embodiment are obtained by one process;

[0046] Another example Figure 4 As shown, the first substrate 210...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com